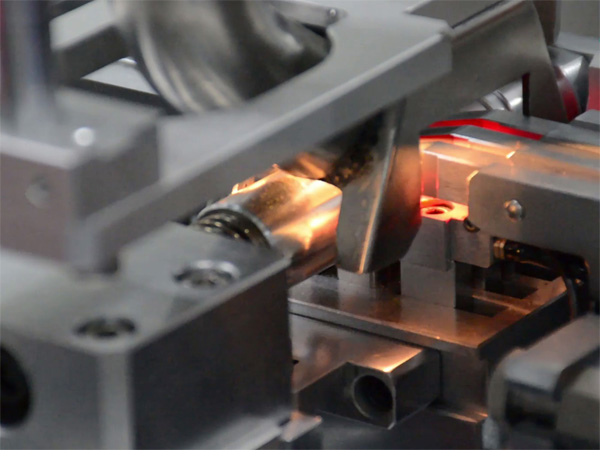

Automatic Welding

With the development automation technology, automatic welding technology is more advanced. Automatic welding machine plays an important role in the application of various industries, and its application is expanding rapidly. In the modern industrial production, the mechanization and automation of the automatic welding processare the inevitable trends of the manufacturing industryfor auto welding machine manufacturers. The automatic welding machine and supplywith automatic welding systemswe provided, with more efficient, high welding precision and fast welding speed, can be widely used in many fields.

In the past 20 years, with the development of digital, automation, computer, mechanical design technology and the importance of welding quality, automatic welding has developed into an advanced manufacturing technology, and role automatic welding equipment plays in various industrial applications is more and more important, and the scope of application is expanding rapidly. In modern industrial production, the mechanization and automation of the welding production process is an inevitable trend in the modernization of the welding mechanism manufacturing industry.

According to the degree of automation, automated welding equipment can be divided into the following three categories:

- Self-adaptive control automatic welding equipment The adaptively controlled welding equipment is a highly automated welding equipment, which is equipped with sensors and electronic detection lines, it can automatically guide and tracks the weld trajectory, and implements closed-loop feedback control of the main welding parameters. The entire welding process will be completed automatically according to preset procedures and process parameters.

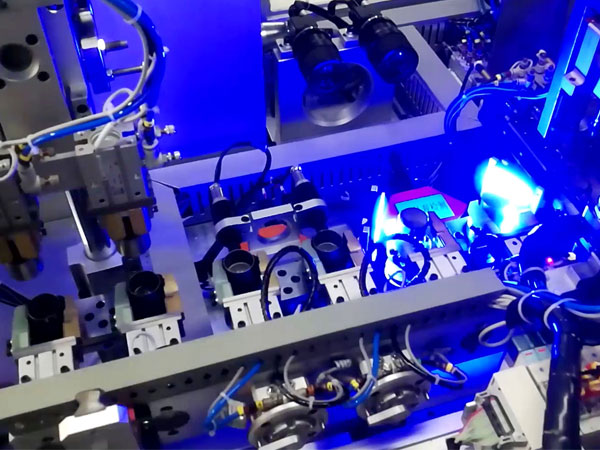

Intelligent automatic welding equipment

It utilizes a variety of advanced sensing components such as vision sensors, tactile sensors, auditory sensors and laser scanners etc., and it makes uses of computer software systems, databases and expert systems with functions such as identification, judgment, real-time detection, calculation, automatic programming, welding parameters storage and the ability to automatically generate weld log files.

The composition of automated welding equipment:

Application and value of automatic welding equipment in all-position welding

First, the automatic welding equipment is applied in the all-position welding, and the welding execution part is driven by the rotary pair to flexibly and reasonably change the posture of the welding torch, which is beneficial to the all-position welding work. At the same time, the motor power can be reduced while driving the same welding actuator. In the application, it is better to install the sensor at the welding position on the final stage deceleration shaft to detect the position of the welding gun. With this installation method, the control precision obtained is relatively high. In addition, by means of this memory on the automatic welding equipment, the parameters of the welding process and the weld tracking control program are stored, and the welding process parameters are stored in the arc welding power source, so that the advantages of the arc welding power source are further exerted. Through the cooperation of the two, it effectively solves various quality problems that may occur in all-position automatic welding operations.

Secondly, the driving of the welding torch is carried out by means of a stepping motor (the stepping motor is an open-loop control element stepping motor part that converts the electric pulse signal into angular displacement or line displacement). The digital input pulse model is effectively converted into a rotary motion by this motor. The accuracy of the component itself is high, and there is neither drift problem nor problems such as accumulated error. The application of this component in all-position welding not only keeps the rotational speed unchanged, but also controls the frequency signal to be relatively stable, and the torch displacement is more accurate.

Thirdly, in the all-position welding operation, the welding head and the arc welding power source are organically combined, which not only can achieve the purpose of full-position automatic welding, but also can reduce the price of the automatic welding equipment to a certain extent. In this way, not only can automatic welding be achieved, also the semi-automatic welding can be carried out by means of the arc welding power sources and the utilization of the semi-automatic welding torches.

Yiheda specializes in designing and manufacturing the custom automation solution to customers, such as automation equipment, semi automatic welding machine, industrial automation designand custom assembly machine.If you are interested, you can contact us, and we will share automatic welding machine pdfand our automatic welding machine price.

Send product request

Other supplier products

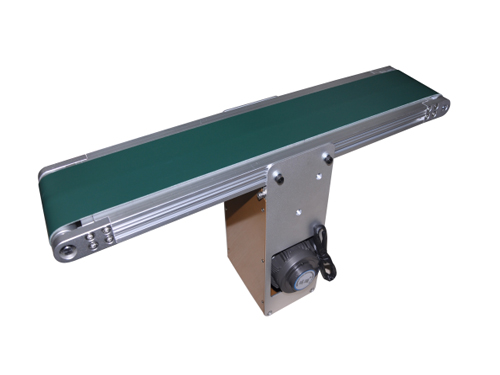

| Conveyor | The conveyor includes flat belt conveyor, synchronous belt conveyor, plastic chain conveyor, nets chain conveyor, jig straight return conveyor, spe... | |

| Visual Inspection | With the combination of lighting, image and data processing, the visual inspection system can detect and monitor the production process and product... | |

| Belt conveyor (Short type) | The conveyor works with automatic machine and other conveyors. There are many kinds of materials that can be conveyed by the conveyor, with complet... | |

| Electromagnetic Core Assembly Line | Electromagnet is one of automotive engine accessories, automotive engine electromagnet assembly machine is fully automatic production machines. The... | |

| Central Bolt Automatic Assembly Line | Machine Features ofCentral BoltAssembly Line Automation Equipment 1. Frame: The safety guard door frame uses aluminum alloy profiles2. Machine part... |

Same products

| RESSA RMD-RPB02 Mortised Automatic Door Sweep | Seller: HEILONGJIANG RESSA CO., LTD. | When the door is opened, the internal seals of RESSA automatic door sweep will automatically rise... | |

| RESSA RMD-RPB01 Mortised Automatic Door Sweep | Seller: HEILONGJIANG RESSA CO., LTD. | When the door is opened, the internal seals of RESSA automatic door sweep will automatically rise... | |

| HRTC-B1 Control Modules | Seller: Tinko Instrument (Suzhou) Co., Ltd. | Tinko HRTC-B1 plc temperature moduleis a LED display with dual row and dual colors module. It is ... | |

| Hot Runner Control Modules | Seller: Tinko Instrument (Suzhou) Co., Ltd. | As basic unit of hot runner control system, hot runner control module consistent temperature cont... | |

| Hot Runner Controller | Seller: Tinko Instrument (Suzhou) Co., Ltd. | Hot runner temperature controller systemsplay a particularly important role in injection molding ... |