GYTA / GYTS Fiber Optic Cable

The structure of GYTA cableis that single-mode or multi-mode optical fiber is sheathed in a loose tube made of high modulus polyester material, and the tube is filled with waterproof compound. The center of the cable core is a metal reinforced core. For certain GYTA fiber cableor gyts fiber optic, a layer of polyethylene (PE) needs to be squeezed outside the metal reinforced core. The loose tube (and filling rope) is twisted around the central reinforcing core to form a compact circular cable core, and the gaps in the cable core are filled with water blocking fillers. Plastic-coated aluminum tape (APL) is longitudinally wrapped and then extruded into a cable with a polyethylene sheath.

As one of the professional fiber optic accessories suppliers, TUOLIMAcan customize the optical cable according to your requirements. If you need any technical support, we will also recommend the most suitable and cost-effective customized ADSS fiber optical cablefor you according to the use environment, laying method and terminal customer requirements of the optical cable. You can check the details of our gyta53 fiber cablebelow. If you have any questions, feel free to consult.

Specification of GYTA Fiber Optical Cable

|

Test |

Standard |

Specified value |

Acceptance criteria |

|

Tension |

IEC 794-1-E1 |

Short term (during installation): 1500N |

Short term tension: Every fiber in the cable elongation rate should be less than 0.33%, after the tension deleted, no fiber attenuation change happens. |

|

Long term (during operation): 600N |

Long term tension: The optical fiber shall have no distinct additional attenuation and strain. |

||

|

Crush |

IEC 794-1-E3 |

Short term (during installation): 1000 N/100mm |

Short term: Δα<0.2dB |

|

Long term (during operation): 300 N/100mm |

Long term: The optical fiber shall have no distinct additional attenuation and strain. |

||

|

Impact |

IEC 794-1-E4 |

500g, 1m |

The optical fiber shall have no distinct additional attenuation and strain after test. |

|

Repeated bending |

IEC 794-1-E6 |

15kg |

The optical fiber shall have no distinct additional attenuation and strain. |

|

Torsion |

IEC 794-1-E7 |

15kg, ±180° |

The optical fiber shall have no distinct additional attenuation and strain. |

|

Temperature cycling |

IEC 794-1-F1 |

-40℃~+70℃, 2 cycles |

Δα<0.2dB/km |

|

Water penetration |

IEC 794-1-F5 |

Sample 3m, water 1m, 24h |

No water leakage |

|

The tolerable bend radius of the cable |

Dynamic (during installation): |

||

|

20xCable OD |

|||

|

Static (during operation): |

|||

|

10xCable OD |

|||

|

Service Life Time |

25 years |

Test Requirement of GYTS Fiber Optical Cable

|

No |

Item |

Test standard |

Method |

Acceptance criteria |

|

1 |

Tensile |

IEC-60794-1-E1 |

-Fiber strain at maximum |

|

|

test |

Sample length:50 meters |

Load: max. 0.33% |

||

|

Time: 1minutes; |

-Attenuation increase≤0.1dB |

|||

|

2 |

Crush |

IEC-60794-1-E3 |

Load:1000N |

-No splits or cracks in the |

|

test |

Time: 1 minutes |

outer jacket; |

||

|

Length: 100mm |

-Attenuation increase<0.1dB, (After the test) |

|||

|

3 |

Impact |

IEC-60794-1-E4 |

Impact energy: 450g |

-No splits or cracks in the outer jacket |

|

test |

Height:1 meter |

-Attenuation increase≤0.1dB(After the test) |

||

|

Impact points: min.1 |

||||

|

Number of impacts: 5 |

||||

|

4 |

Repeated bending |

IEC-60794-1-E6 |

R=20×cable outer diameter |

- No splits or cracks in the outer jacket |

|

1m cable length with 150N weight,30 cycles |

-Attenuation increase ≤0.1dB(After the test) |

|||

|

5 |

Torsion |

IEC-60794-1-E7 |

1m cable length with 150N weight |

- No splits or cracks in the outer jacket |

|

test |

±180 degrees, 10 cycles |

-Attenuation increase ≤0.1dB(After the test) |

||

|

6 |

Bending |

IEC-60794-1-E11 |

Diameter of mandrel: 20×D |

- No splits or cracks in the outer jacket |

|

test |

Number of turns/helix:10 |

- No fiber break |

||

|

Number of cycles: 5 |

||||

|

7 |

Temperature cycling test |

IEC-60794-1-F1 |

Temperature step: +20℃→-40℃→+60℃→-40℃→ |

-Attenuation variation for reference value(the attenuation to be measured before test at +20±3℃) ≤0.1dB/km, |

|

+60℃→+20℃ |

||||

|

Time per each step: 12 hrs |

||||

|

Number of cycles: 2 cycles |

||||

|

8 |

Water penetration test |

IEC-60794-1-F5 |

Water height: 1m |

-No water leakage at the end of the sample |

|

Sample length:3m |

||||

|

Duration of test: 24hrs |

||||

|

9 |

Drip test |

IEC-60794-1-E14 |

Five 0.3m samples suspended vertically in a climate chamber, raised temperature to +70℃ |

-No filling compound shall drip from tubes after 24 hr |

Packing and Comments of GYTA Fiber Optic Cable

Packing material: Non-returnable wooden drum.

Both ends of cable are securely fastened to drum and sealed with a shrinkable cap to prevent ingress of moisture.

Cable printing: The sequential number of the outdoor optical cable length shall be marked on the outer sheath of the cable at an interval of 1meter ± 1%.

The following information shall be marked on the outer sheath of the cable at an interval of about 1 meter.

Cable type and number of optical fiber

Manufacturer name

Month and Year of Manufacture

Cable length

Drum marking: Each side of every wooden drum shall be permanently marked in a minimum of 2.5~3 cm high lettering with following:

Manufacture name and logo

Cable length

Cable type and number of fibers

Roll way

Gross and net weight

Send product request

Other supplier products

| Rack Mount Patch Panels | As a fiber optic products supplierin the world, TUOLIMA has been operating in the optical communication industry since 2009, mainly fabricating and... | |

| Fiber Optic Terminal Box | Optical termination box (OTB), is a compact fiber management box used for FTTH application. Fiber optic cable terminal boxincludes faceplate and dr... | |

| C201 C202 C304 Stainless Steel Cable Strap | The stainless steel banding can guarantee extended service life; and attaching under significant mechanical loads. Minimal breaking load is also... | |

| Fiber Optic Tool Kits | A fiber optic tool kit contains go-to equipment. A must for any professional technician. With the correct product selection in portable cases, t... | |

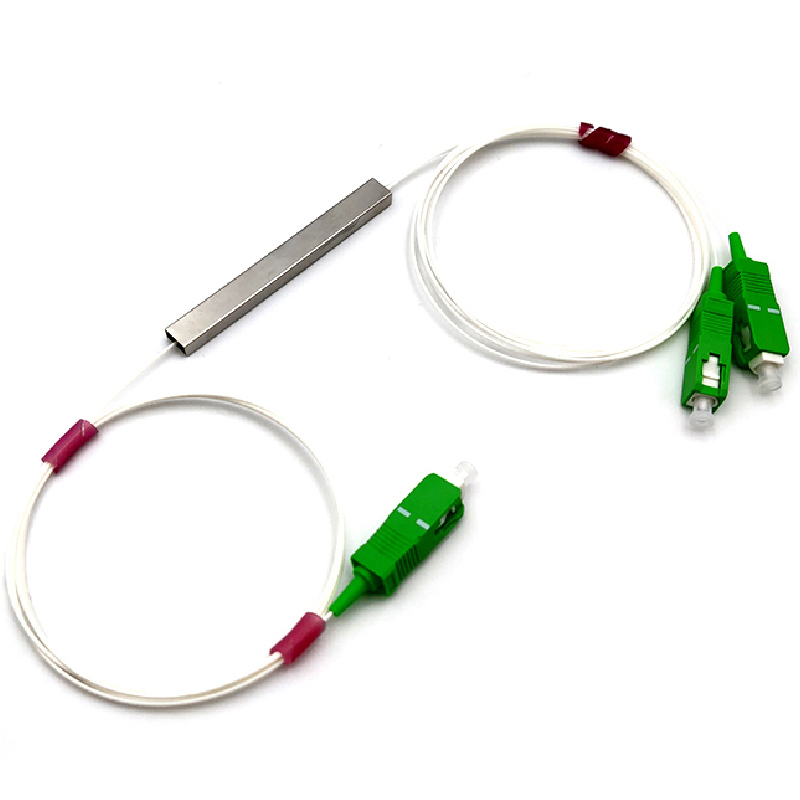

| 1*2 Mini Fiber Optic Splitter | Optical splitter is a part of passive components (also called optical passive components) in the process of optical transmission. Like coaxial cabl... |

Same products

| YCS MAi 6-in-1 Power Cable for iPhone 6S -14 Pro Max Android Huawei | Seller: China PHONEFIX Technology Co., Ltd | YCS Soldered MAi Power boot Cable for iPhone 6S-X/11/12/13/14 Pro Max, Huawei Mate40, Xiaomi and ... | |

| Car CarPlay Super Fast Charging Cable USB Type-C Lightning Data Cord for iPhone and Android | Seller: Phonefix | Description Super Fast Charging Retractable Car Spring USB Type-C Data Cable with CarPlay Compati... | |

| QianLi iCopy Plus 2.2 Mobile Programmer for iPhone | Seller: Phonefix | Description Qianli iCopy Plus programmer 2024 version 6 in 1 set for iPhone Face ID True Tone Bat... | |

| MIJING DY-11 Phone Repair Power Cable for iPhone 8-16 iOS Android | Seller: Phonefix | MiJing DY-11 Mobile Phone Repair Power Cord with iOS & Android FPC for iPhone 8/X/11/12/13/14... | |

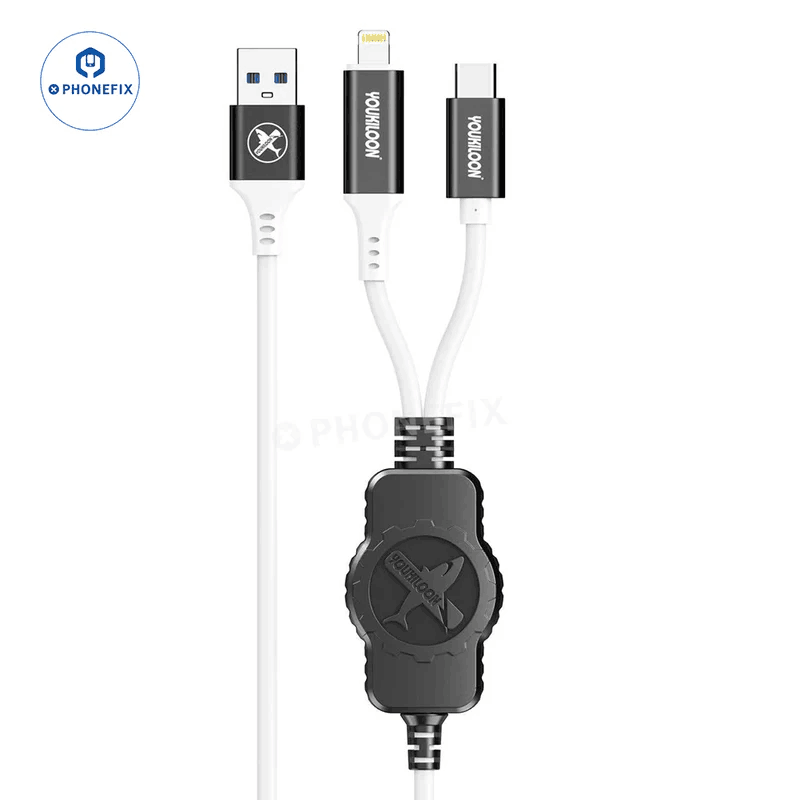

| YOU-IR2 Restore Easy Lightning Type-C 2-In-1 Recovery Cable for iPhone YOU-IR2 Restore Easy Lightning Type-C 2-In-1 Recovery Cable for iPhone | Seller: SHENZHEN PHONEFIX TECHNOLOGY CO.,LTD (CHINA PHONEFIX) | Description YOUKILOON YOU-IR2 Restore-Easy Cable with Lightning Type-C dual interface fo... |