Precision Shaft

Atlas metal manufactures high-quality precision shaft, available off-the-shelf or made to your exact needs. Atlas metal offers you all kinds of precision machining, milling, tapping and drilling in aluminum, stainless steel, steel alloys, and titanium.

Types of Precision Shaft

Fan Shaft

Atlas metal have 15 years experience in fan shaft, we offer fan shaft from OD 1.0mm to 12.0mm, which can be used in different motor fans.

Electric Toothbrush Motor Shaft

Besides the normal CNC turning process, we also can handle Sonic motor shaft in our special process, which leads better efficient and lower your budget.

Micro Shaft

We are very proud of our micro shaft, we are now sharing about 40% of the micro shaft in the whole world. We are able to control 0.6mm common vibrating motor shaft in tolerence of +-0.0002mm.

Auto Shaft

Ferrari, BMW, Mercedes, you can find our production in all the popular cars. Our products are widely used in fuel pump, water pump, air condiction valves.

Precision Shaft Alignment Benefits

Reduced Energy Consumption

Significant power savings can be made through accurate alignment. Precise alignment eliminates reaction forces and reduces energy consumption by up to 10%

Reduced Incidence of Repairs

Mechanical seal repairs decline by up to 65% when precision alignment is carried out on a regular basis.

The rate of repairs declines by up to 30% when precision laser alignment becomes an integral part of the pump repair schedule. Maintenance costs are also reduced through lower parts expenses and inventory levels.

Longer Machine Life

Relation between offset and bearing life cycle: The smaller the offset misalignment, the greater the expected bearing life cycle.

How the Shaft Manufacturing Process Works?

The most common process used to manufacture shafts is via CNC turning. Using this technique, workers or automated processes affix or clamp bars of materials to chucks and rotate them. While rotating, specialized tools use cutting and other subtractive processes to create and shape the end product.

As a leading metal products supplier, Atlas metal uses many different machining processes to create its precision ground shaft. Our facility houses a wide range of state-of-the-art equipment designed to optimize even the most complex aspects of the shaft-manufacturing processes. From custom tooling and fixturing to multi-axis equipment, we use all types of machinery to produce extremely precision shaft to tolerances within 0.00002mm.

Atlas Metal's Shaft-Manufacturing Capabilities

Atlas works with over three dozen types of raw materials to produce high-quality precision ground shafting that adhere to client specifications. We build shafts from materials ranging from.

Custom Precision Shaft Features

Atlas metal offers machined shafts to meet your custom requirements. Shafts are a key component in most rotating equipment. Shaft size greatly affects the torque characteristic in these machines. Hence, the precise design and prototyping of shafts is crucial for all applications.

Shafts at Atlas metal are available with diameters ranging from 0.010 to 1.00 inches and lengths ranging from 0.03 to 3 inches. Precision ground shafts, steering shafts, welded shafts, motor shaft, precision long turned shafts, auto shaft, linkages and component assemblies are some examples of the types of shafts we can produce. Our shafts have tight tolerance values of ± 0.00003 inches and are manufactured from materials of the finest quality.

Custom Precision Shaft Material

Atlas metal offers Products made of alloy steel, carbon steel, or stainless steel, and then case-hardened, through-hardened, or annealed. Alloy steels are ferrous alloys based on iron, carbon and high to low levels of alloying elements such as chromium, molybdenum, vanadium and nickel. Alloy steels have better hardenability properties than carbon steels. They also offer superior durability.

Stainless steels are corrosion-resistant, ferrous alloys that contain chromium or nickel additions. Precision shafting that is case-hardened is hard at the surface, but relatively soft at the core. Products that are through-hardened have the same hardness throughout the stainless steel shaft. Unhardened or annealed precision shafting is also available.

Over the years, the international department evolved to manufacture custom wire and metal products for many industries, including the medical, aerospace, automotive, home appliance, sporting goods, and foodservice industries. We are pleased to see our wire and metal products in such a broad range of industries and to be the OEM wire and metal supplier of choice for many companies. Manufacturing custom metal forms and wire products is our passion!

Other supplier products

|

|

Dual Hook Small Tension Spring |

Spring steels most commonly used in our process for manufacturing Extension Springs are Oil Tempered, Chrome Silicon, Music, and Stainless Steel wi... |

|

|

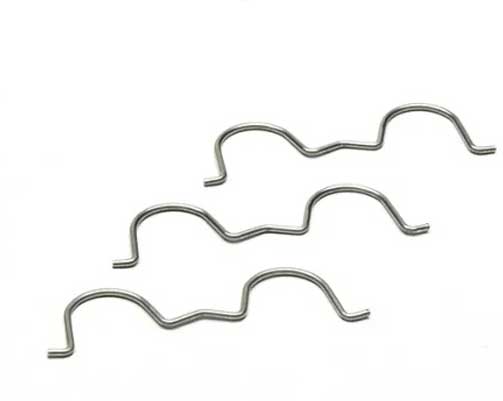

Bending Stainless Steel Wire |

There are no overall design equations for wire forms, meaning we will work with you to determine the best material, sizing, and manufacturing proce... |

|

|

Steel Wire Forming |

Steel Wire Forms

We also offer a wide range of finishing options on most fabrications including meeting OEM specifications or industry standards... |

|

|

Custom SS Compression Spring for Soap Dispenser Sprayer |

Custom SS Compression Springsfor Soap Dispenser Sprayer

Springs for lotion pump, spray bottle, soap dispenser, trigger sprayer is one of the the b... |

|

|

Bending Spring |

Internal Bending Springs

As a custom electrical conduit bending springmanufacturer, Atlas metal can produce custom springsto meet your specific ... |

All supplier products

Same products