CN089 SMT Wave Soldering Machine Lead Free 670KG Weight With PID Control

CNSMT 10 years production WAVE SOLDERING MACHINE after dip component

Feature

| P C Broad width | Board width | Max200mm |

| PCB conveyor height | PCB transportation height | 700±20mm |

| PCB conveyor speed | PCB transport speed | 0-1.8m/min |

| Preheating length | Preheat zone length | 400mm |

| Preheating Temperatures | Preheat zone temperature | Room temperature ~ 180 degrees |

| Suitable solder type | Suitable solder type | Lead-free solder, ordinary solder |

| Preheating capacity | Preheat power | 2KW |

| Wave solder pot | Wave soldering furnace power | 6KW |

| Solder volume | Solder tin capacity | Lead-free 120KG |

| Solder temperature | Tin furnace temperature | Room temperature ~300 degrees |

| Temperature control | Temperature control method | PID control, SSR drive |

| Flux storage tank | Flux capacity | Max5.2L |

| Power requirements | power supply | 3-phase or single-phase 220VAC |

| Power for heating up | Starting power | 8KW |

| Power for operation | Normal operating power | 2.0KW-2.5KW |

| Air supply | Gas source | 4-7kg/cm2 12.5L/min |

| Control fashion | Whole control method | PLC+ Meter/PLC+Touch Screen |

| Weight | weight | Max 350kg |

| Dimensions | Dimensions | L2200xW1100xH1500 |

Application

Wave soldering machine basic operating procedures

(Reference)

B1 wave soldering machine basic operating procedures

B1.1 Preparation

a. Check whether the wave soldering machine is equipped with ventilation equipment is good;

b. Check the wave soldering machine timing switch is good;

c. Check if the tin bath temperature indicator is normal.

Method: Adjust the temperature indicator up and down, and then use a thermometer to measure the temperature of the tin bath surface 10-15 mm, and determine whether the temperature changes with it:

d. Check whether the preheater system is normal.

Method: Turn on the pre-heater switch and check if it is warm and the temperature is normal.

e. Check the operation of the cutting knife.

Method: Adjust the height of the blade according to the thickness of the printed circuit board and the length of the remaining component lead. Then tighten and stabilize the blade holder, start the visual inspection of the rotation of the blade, and finally check the failure of the insurance device;

f. Check whether the supply of compressed air to the flux container is normal;

Method: Pour the flux, adjust the inlet valve, start the flux foam, use the sample board to adjust the foam to 1/2 of the plate thickness, and then tighten the IOP valve until the formal operation. Then move this valve, just open the air intake switch;

Send product request

Other supplier products

| Black Color Fuji Nxt SMT Feeder Calibration Accuracy Machine With Computer | KJW-M1110-00 BODY ASSY 1 KJW-M112A-00 RACKING LEVER ASSY 1 KJK-M1120-00 SPROCKET ASSY 1 1 BODY 1 2 KJK-M1112-01 KNOCK PIN (FRONT) 1 3 ... | |

| YAMAHA YV100XG SMT Feeder CL24MM Pnematic Type Lightweight For Smt Factory | KHJ-MC501-00 BODY,FEEDER 12 KHJ-MC502-00 COVER,FEEDER 13 KHJ-MC106-00 PLATE,UNDER 14 KHJ-MC206-00 PLATE,UNDER 15 KHJ-MC50C-00 SEAL,MAIN LABEL 16 KH... | |

| Feeder JUKI FF12MM Lightweight For Assembly Full Line | JUKI FEEDER FF12MM FF16MM 24MM 32MM 44MM 56MM SMT FEEDER IC Component led feeder AQ02HP AQ02HP AF05HP AF081E AF08HE AF081P AN05HP AN081E AN08HE AN0... | |

| KHN-M7710-A1X 9498 396 02247 SMT YAMAHA NOZZLE 301A YS24 YG12 YS12 Original | KHN-M7710-A1X Part nr.: 9498 396 02247YAMAHA Original New 301A NozzleKHN-M7710-A1X YG12 Nozzle YS12 YS24 YG300 Nozzle YAMAHA 301A NozzleKHN-M7710-A... | |

| SMT fuji Nozzle NXT XP142 XP141 XP243 XP241 ORIGINAL NOZZLE FOR FUJI pick and | SMT fuji Nozzle NXT XP142 XP141 XP243 XP241 ORIGINAL NOZZLE FOR FUJI pick and place mahcineFUJI CP742 CP743 CP842 DGPK0131 PLATEFUJI CP732 CP733 SH... |

Same products

| Hc-501s Low Noise Energy Saving Rotary Air Blower | Seller: Greentech International (Zhangqiu) Co., Ltd | HC rotary air blower structure and working principleThe rotary blower has an exquisite structure ... | |

| Common Rail Injector Nozzle 880P119092 Common Rail Injector Nozzle A6510702887 | Seller: China lutong | Common Rail Injector Nozzle 880P119092 Common Rail Injector Nozzle A6510702887Chris Whats/ app:+... | |

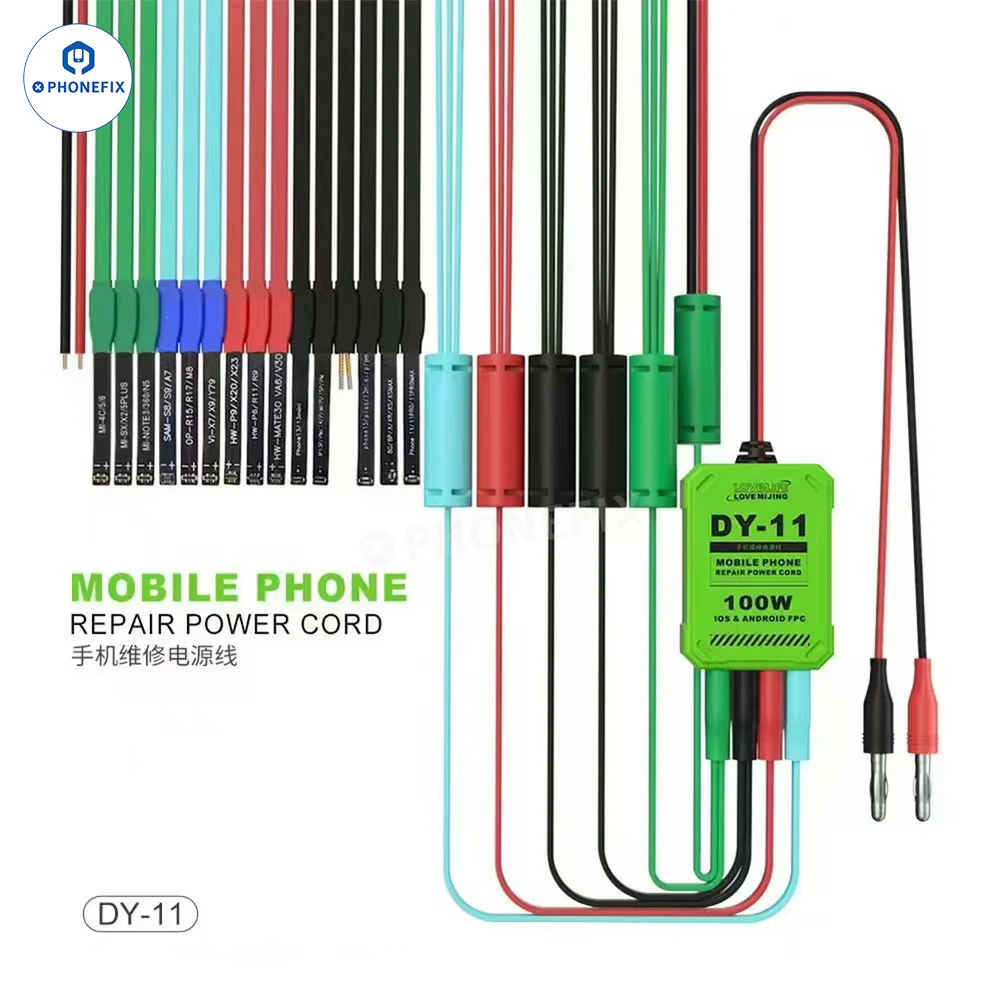

| MIJING DY-11 Power Cable for iPhone and Android Phone Boot Testing | Seller: Phonefix | The MiJing DY-11 mobile phone repair power cable uses iOS and Android FPC interfaces, specificall... | |

| AI845 Analog Input Module 3BSE023675R1 | Seller: Hangzhou Perfect Technology Co., Ltd. | General Information Product ID: 3BSE023675R1 Medium Description: AI845 Analog Input Module, 8 c... | |

| T9401 T9402 Digital Input Module | Seller: Hangzhou Perfect Technology Co., Ltd. | The 9401 (8 channel) and 9402 (16 channel) are 24Vdc digital input modules. They accept galvanica... |