G1 Solar Cell

G1 solar cell sizeplays an important role in the first unified standard size of monocrystalline percin the module. G1 perc bifacial solar cellsize is 158.75mm, which has the advantages of lower production costs, higher power, and higher acceptance of the cell side on the premise of specsquare monocrystalline silicone sheet with thickness and diagonal line.

Sunrise Energy selected global high-quality G1 cells, equipped with non-destructive scratches, 9BB half cell, precision encapsulation, and other technologies, which can achieve the power of 415W.

High Precision , High Flatness Screen Printing

Solar Cells with high welding ability, optimized template design, zero defect appearance

Advanced PECVD Film

MBB solar cell with silicon nitride anti-reflective coating. Uniform navy blue

Perfect Texturing

MBB solar cell with monocrystal pyramid pattem surface and polycrystalline silicon volute pattern surface High nucleation density, large receiving area, low reflectivity

Sophisticated Warranty

MBB solar cell with parallel resistance test to reduce hot spot effect and test weak light response Precise and efficient selection of chips, sorted into 12 levels according to the power of a single chip, Accuracy up to + 0.1% Appearance sorting to ensure that all cells in the assembly are similar in color

G1 solar cell size is 158.75-158.75mm. The dicing process in module production is divided into full and half. There are 5BB and 9BB. The appearance of Sunrise selection is zero defects. G1 solar cell size mono cell with higher welding ability, considering cell efficiency, production yield, and market analysis, it is confirmed that 9BB is the best solution. Innovative PERC technology and 9BB design shorten the current transmission distance and reduce the resistance loss. So that the conversion efficiency of the MBB solar cellcan be improved, and the impact on the performance of the perc modulesis reduced.

9BB P-type bifacial half-cut cell can contribute up to 30% of the gain in the module power generation process. The half-cut cell technology has higher conversion efficiency than the full cell and has a lower rated operating temperature. Compared to the full cell module, the half cell module temperature is 2-3 degrees lower, and the hot spot temperature is 10-20 degrees lower. At the same time, MBB solar cell has a lower shadow mask loss.

It has better IAM performance than conventional flat ribbons when light is incident. The 9BB with a smaller ribbon design can reduce the impact of stress. Make the module resistant to high and low-temperature performance and mechanical load performance.

Applications of the G1Solar Cells

G1 cell is mainly used in 120, 132, 144 cell solar modules. It is representative of small size modules. The G1 module is encapsulated by Sunrise G1 solar cell with power up to 415w, and also provide full black, double glass andperc bifacialhalf cell and other customization.

As a solar products company, we can offer kinds of solar products chinafor sale, if you have needs, please leave us a message.

Send product request

Other supplier products

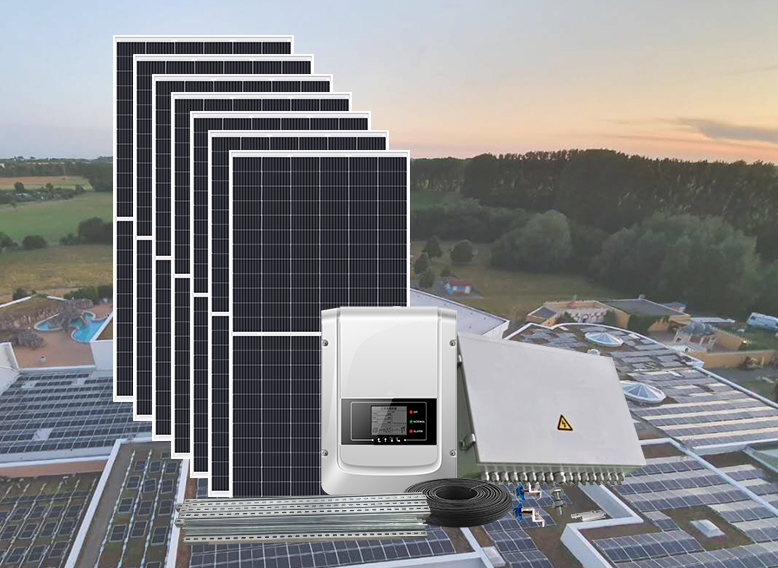

| Off Grid Industrial Solar Panels | The commercial off grid solar systems based on module design is also more widely used. It consists of solar modules, controllers, inverters, batter... | |

| MONOCRY STALLINE SOLAR CELLS | single crystalline solar cell monocrystalline solar cell efficiency difference between perc monocrystallineand polycrystalline solar cells Usi... | |

| Monocry Stalline Solar Cells | Perc MonocrystallineStalline Solar Cells Using diamond wire cutting technology and thin manufacturing technology, with high precision and high f... | |

| G12/M6 SERIES SOLAR MODULES | The Zeus series has enhanced module density and significantly increased module power and efficiency, with an output power of 505-605w. It also has ... | |

| On Grid Industrial Solar Panels | The industrial solar energy systemsbased on component design is different from the small and sophisticated households, but more large and complete.... |