Non-Alcohol Beer And No Alcohol Wine

Wine Separation and Extraction System Ideal Choice for wineries And Beer

Product Overview

JS-WSU-M2serie products are specially designed tomeet the brewing needs ofwineries. This wine extraction systemis different from the traditional pot distillation and extraction method. By using our unique wine ceramic membrane technology, the wine can be perfectly separated into brandy and alcohol-free wine without any waste liquid production, increase production, and significantly reduce energy consumption, and the brandy extracted by this system, with thorough removal of impurities, pure taste and natural fragrance.

Lower energy consumption, more compact footprint, better process control, no waste liquid production and a substantial increase in production capacity enable wineries of all sizes to further reduce operating costswhilemaintaining absolute respect for the quality characteristics of brandy.

Cost saving and good economic efficiency

Our JS-WSU-M2 series products adopt a new extraction process different from the traditional brandy brewing process, which makes the winery achieve lower energy consumption, better output and zero waste liquid production while ensuring the quality of brandy. The process characteristics of this series of products include:

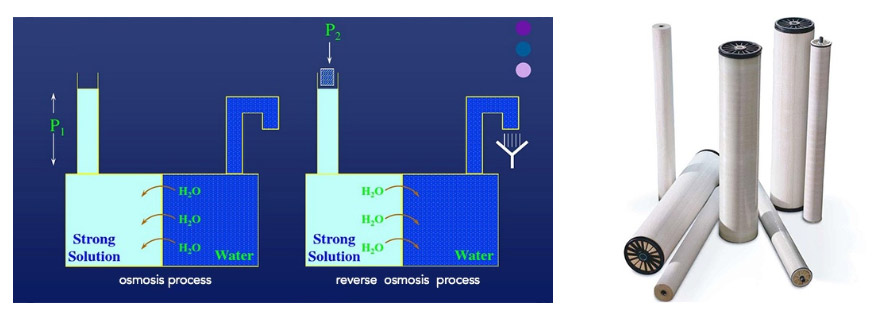

Wine membrane technology

Wine Membrane is a preferential selective membrane specially designed for wineries. Wineries can separate wines into brandy and alcohol-free wines in reliable, repeatable and single process steps. Wine Membrane products have been proved to have good selective separation and solvent resistance. It can ensure that the wine body is not polluted, and greatly increase the output.In addition: equipped with full automatic control, and a small footprint, is the ideal solution for extracting brandy from wine.

Composition of the membrane module:

Membrane: Special Composite Membrane Material

Pouring: Food grade epoxy resin

Sleeve: Food grade polypropylene wrapping net

Shell: Food grade 304 stainless steel

Sealing: Soft food grade epoxy resm

JS-WSU-M2 Series Components:

Feeding system

Membrane Separation System Vacuum system

Condensing system

Heating system

Electrical appliances and control systems

Executive standard

GB 4806.1 -2016 National Food Safety Standard General Safety Requirements for Food Contact Materials and Products

GB 31604.1 -2015 National Food Safety Standard General Rules for Migration Tests of Food Contact Materials and Products GB 4806.9 -2016 National Food Safety Standard Metal Materials and Products for Food Contact

Operating environment

|

Inlet pressure |

0-5 bar |

Raw material temperature |

40--45°C |

|

Vacuum pressure |

4000-8000Pa |

Condensation temperature |

-10 –15°C |

JIUWUis a professional Ceramic membrane factory, JIUWU is willing to offer you high quality products.

Send product request

Other supplier products

| Organic Membrane Filtration System | OMS skid-mounted (Organic Membrane FiltrationSystem) refers to a form of overall combination of equipment frame and whole equipment. Organic membra... | |

| EDI (Ultra-Pure Water System) | As a core technology, JIUWU has become the largest ceramic membraneelement producer and a world leader in cross-flow filtration.Electrodeionization... | |

| RO Membrane Technology | Reverse osmosis (RO) is a water purification technology that uses a semipermeable membrane to remove ions, molecules, and larger particles from dri... | |

| Ceramic Membrane Filtration System | Skid-mounted device ()effectively allocates and stores machine for process and modular systems in the field of solid-liquid separation.A CMF skid-m... | |

| Nanofiltration Ceramic Membrane Element | Ceramic Nanofiltrationmembrane is relatively recent membrane filtration system, with the purpose of softening and removal of disinfection by-produc... |

Same products

| Ceramic Beads (Foundry Spherical Sand) | Seller: Hebei Chida Manufacture and Trade Co., Ltd | Ceramic Beads (Foundry Spherical Sand) Product Description Ceramic beadsis high grade green cas... | |

| Machining Service In Machinery And Equipment | Seller: DONGGUAN SIBAI METAL WORKS LIMITED | Mechanical equipment refers to one or a group of devices, that have a certain mechanical structur... | |

| Conjoined Cartridge | Seller: NINGBO WANHAI CARTRIDGE TECHNOLOGY CO.,LTD | Ceramic disc cartridges are simply two ceramic discs with holes through them. One disc is held in... | |

| Wanhai Cartridge 40H-6 40mm High Torque Cartridge with Distributor | Seller: NINGBO WANHAI CARTRIDGE TECHNOLOGY CO.,LTD | Minimum Opening Angle 23° Maximum Turning Angle 100° Maximum Temperature 95°C Leve... | |

| Wanhai Cartridge 40H-2 40mm Cartridge with Distributor | Seller: NINGBO WANHAI CARTRIDGE TECHNOLOGY CO.,LTD | 40H-2 40mm Tap Valve Cartridge Minimum Opening Angle 23° Maximum Turning Angle 100° Max... |