GSET-551 Steel Wire Eddy Current Flaw Detector 1024

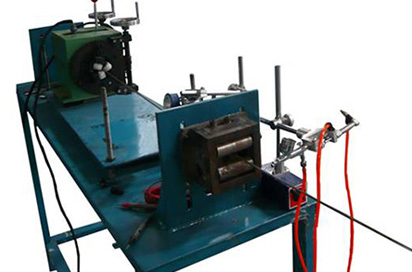

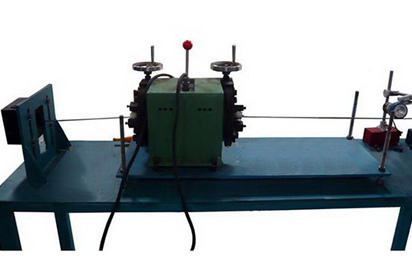

GSET-551 Steel Wire Eddy Current Flaw Detector Brief

Using the eddy current signal processing method and high-performance DSP algorithm, the NDT wire rope testerdetection ability of micro-crack is as high as 0.05mm deep crack.

Using computer digital technology and "digital eddy current detection technology" to achieve high-speed data processing capabilities, detection speed can be reached to 1~500m/min. Technology can effectively suppress all kinds of interference signals. It has waveform, amplitude, phase, X-axis and Y-axis signals.

The professional "digital filtering" is adopted to effectively suppress the interference signal in the field and ensure the accuracy and stability of the detection.

Features of GSET-551 Steel Wire Eddy Current Flaw Detector

The detector detects the minimum metal cross-sectional area change and the minimum length of the damage length corresponding to the local damage.

The detector detects the minimum metal cross-sectional area change and the damage length minimum size corresponding to the metal cross-sectional area loss.

The maximum value of the random error obtained by performing multiple consecutive measurements of the same metal cross-sectional area change in the same test sample under the same test environment and conditions within the instrument range.

Within the range of the instrument, the metal cross-sectional area of the test sample is linearly proportional to the absolute value of the maximum deviation between the measured curve of the instrument and the calibration curve fitted by the measured value of the cross-sectional area of the metal.

The value of the metal cross-sectional area loss measured by the instrument minus the actual value of the metal cross-sectional area loss within the instrument's range.

In the range of the instrument range, under the condition of the length loss of the cross-sectional area of the metal, the cross-sectional area loss of the metal on the wire rope measured by the detector is matched with the value of the loss of the cross-sectional area of a group of wire ropes measured by the instrument. The absolute value of the maximum deviation between the calibration curves.

The detector is capable of detecting the resolved minimum distance.

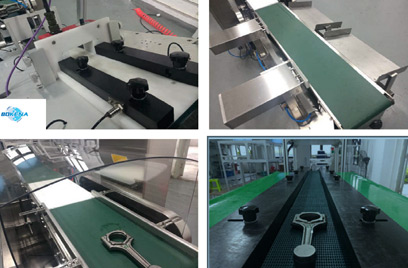

The detector can detect and display changes in metal cross-sectional area loss (LMA) on one channel, and detect and display local damage (LF) on the other channel. The detector recording device can be a computer, graphic recorder or other matches. device.

The detector cannot simultaneously detect and display metal cross-sectional area loss changes and local damage, and can only detect and display one of them. The detector recording signal device can be a computer, a graphic recorder or other matching devices.

The detector principle and composition meet the requirements of the GB/T 21837-2008 standard, and it has a detector for detecting distance display, data storage or recording function.

GSET-551 Steel Wire Eddy Current Flaw Detector performance

|

Detection channel |

Single-channel |

|

Detection speed |

1~500m/min(on-line) |

|

Frequency range |

100Hz-10MHz |

|

gain |

0~99dB,step size 0.1dB |

|

Advanced filtering |

have |

|

High pass |

|

|

Low pass |

1Hz~10000Hz |

|

Phase rotation |

0-360 ° step 1 ° |

|

Synchronized alarm output controlled by an internal and external clock |

|

High precision end and end-to-tail signal removal |

|

High precision real-time, delayed alarm output |

|

Fast digital/analog electronic balance |

|

Memory track delay blanking function |

|

Real-time impedance plane display |

|

The instrument a match any probe |

|

Remote automatic help system |

|

Computer full digital parameter adjustment |

|

Non-equal amplitude phase/amplitude alarm domain |

As one of the most professional ndt testing equipment suppliersin China, BKNhas formed a social scientific research cooperation network with well-known universities and research institutes in China, which has a strong R&D and production capacity. It guarantees the leading and word-class technology position of BKN industrial nondestructive testing technology.

Send product request

Other supplier products

| GTET-02 Cylinder Liner Eddy Current Testing Machine | GTET-02 Cylinder Liner Eddy Current Machine Introduction The rate of missed standard defect is 0%; the rate of false positives (only misidentifi... | |

| EDM Notch | An electric pulse is a pulse generated by electrons, and a pulse is a process of changing a voltage in a short time. Electropulsing is an unsteady ... | |

| GSET-551 Steel Wire Eddy Current Flaw Detector | GSET-551 Steel Wire Eddy Current Flaw Detector Brief Using the eddy current signal processing method and high-performance DSP algorithm, the NDT ... | |

| Portable Magnetic Flux Leakage Testing Equipment | Magnetic flux leakage test refers to the formation of a leakage magnetic field on the surface of a test piece after it is magnetized due to defects... | |

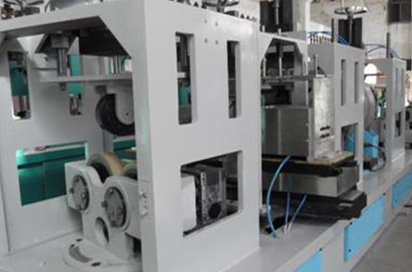

| BKNET-101 Automatic Eddy Current Testing | The eddy current testing (BKNET-101) is a fully automated eddy current inspection systemthat uses large-scale imported integrated circuits combined... |

Same products

| Cash Register Scale BL-A | Seller: SHANGDELI ELECTRONIC INSTRUMENT LIMIED. | The Cash Register ScaleBL-A features a large touch screen display, available in either a 12.1" or... | |

| Cash Register Scale GL-A | Seller: SHANGDELI ELECTRONIC INSTRUMENT LIMIED. | The Cash Register ScaleGL-A is equipped with a capacitance touch screen, which solves the problem... | |

| TDP-B+ Electronic Price Computing Apparatus | Seller: SHANGDELI ELECTRONIC INSTRUMENT LIMIED. | The TDP-B+ digital price computing scaleis a versatile device that offers optional digital filter... | |

| Cash Register Scale ADS-P | Seller: SHANGDELI ELECTRONIC INSTRUMENT LIMIED. | The Cash Register ScaleADS-P is a user-friendly and efficient weighing device that simplifies the... | |

| Double Printing Cash Register Scale DL-A | Seller: SHANGDELI ELECTRONIC INSTRUMENT LIMIED. | Two-in-one checkout and labeling. The Double Printing Cash Register Scale DL-A is a multi-functio... |