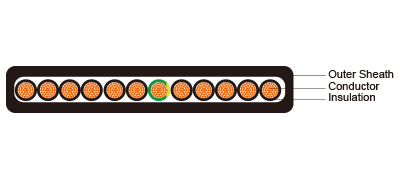

Single Core Cables To IEC 60502

Single Core Medium Cable to IEC 60502-2

Application:

The single core cables are designed for distribution of electrical power with nominal voltage Uo/U ranging from 1.8/3KV to 26/35KV and frequency 50Hz. They are suitable for installation mostly in power supply stations,Website:, indoors and in cable ducts, outdoors, underground and in water as well as for installation on cable trays for industries, switchboards and power stations.

Standards:

IEC 60502 Part 1(1.8/3KV)IEC 60502 Part 2(3.6/6KV to 18/30KV

Conductor:

Plain annealed copper or aluminium complying with IEC 60228/BS 6360. Copper conductors shall be stranded (class 2) and aluminium conductors shall be either solid or stranded (class 2).

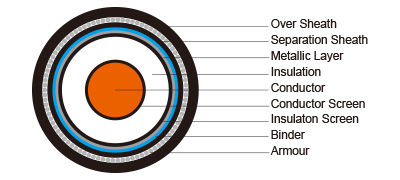

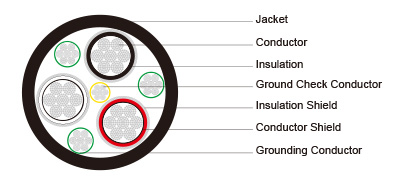

Conductor Screen:

The conductor screen consists of an extruded layer of non metallic, semi-conducting compound firmly bonded to the insulation to exclude all air voids. The conductor screen is not necessary for both PVC and EPR/HEPR insulated 1.8/3KV and 3.6/6KV cables.

Insulation:

Insulation is of polyvinyl chloride (PVC) intended for 1.8/3KV and 3.6/6KV cables, cross-linked polyethylene compound (XLPE) or ethylene propylene rubber (EPR/HEPR).

Table 1. Insulation Thickness Of XLPE Or EPR/HEPR Insulation

Nom. CrossSection Area

Insulation Thickness at Nominal Voltage

1.8/3KV (Um=3.6KV)

3.6/6KV

(Um=7.2KV)

6/10KV (Um=12KV)

8.7/15KV (Um=17.5KV)

12/20KV (Um=24KV)

18/30KV (Um=36KV)

21/35KV (Um=42KV)

26/35KV (Um=42KV)

mm2

mm

mm

mm

mm

mm

mm

mm

mm

XLPE/EPR

XLPE

EPR

XLPE/EPR

XLPE/EPR

XLPE/EPR

XLPE/EPR

XLPE/EPR

XLPE/EPR

Unscreened

Screened

10

2.0

2.5

3.0

2.5

-

-

-

-

-

-

16

2.0

2.5

3.0

2.5

3.4

-

-

-

-

-

25

2.0

2.5

3.0

2.5

3.4

4.5

-

-

-

-

35

2.0

2.5

3.0

2.5

3.4

4.5

5.5

-

-

-

50 – 185

2.0

2.5

3.0

2.5

3.4

4.5

5.5

8.0

9.3

10.5

240

2.0

2.6

3.0

2.6

3.4

4.5

5.5

8.0

9.3

10.5

300

2.0

2.8

3.0

2.8

3.4

4.5

5.5

8.0

9.3

10.5

400

2.0

3.0

3.0

3.0

3.4

4.5

5.5

8.0

9.3

10.5

500 - 1600

2.2-2.8

3.2

3.2

3.2

3.4

4.5

5.5

8.0

9.3

10.5

*Insulation Thickness of PVC is 3.4mm (1- 1600mm sq) for 3.6/6KV cables.

Insulaton Screen: The insulation screen consists of an extruded layer of non metallic, semi- conducting compound extruded over the insulation. The extruded semi-conducting layer shall consist of bonded or cold strippable semi-conducting compound capable of removal for jointing or terminating. As an option, a semi-conducting tape may be applied over the extruded semi-conducting layer as a bedding for the metallic layer. The minimum thickness is 0.3 mm and the maximum resistivity is 500 Ohm-m at 90°C. The screen is tightly fitted to the insulation to exclude all air voids and can be easily hand stripped on site. The insulation screen is not necessary for both PVC and EPR/HEPR insulated 1.8/3KV and 3.6/6KV cables. The screen may be covered by semi-conductive water blocking swellable tape to ensure longitudinal watertightness.Metallic Layer: The metallic layer may be applied over the individual cores or the core assembly collectively.The following types of metallic layers are provided:1) Metallic Screen2) Concentric Conductor3) Metallic Sheath4) Metallic armourThe metallic screen shall consist of either copper tapes or a concentric layer of copper wires or a combination of tapes and wires to provide an earth fault current path. The concentric conductor is applied directly either over the insulation, or over the insulation screen or over an inner covering. The metallic sheath consists of lead or lead alloy applied as a tightly fitting seamless tube. The metallic armour consists of either flat wire armour, round wire armour, and double tape armour.

Table 2. Minimum Total Cross Section Of Metallic Screen

Nom. Cross-Section Area of Cable

Min. Cross-Section of Metallic Screen

DC Resistance of the Copper Wire Screen

mm²

mm²

mm

up to 120

16

1.06

150-300

25

0.72

400-630

35

0.51

800-1000

50

0.35

Separation Sheath (for armoured cable): The separation sheath comprises a layer of extruded PVC, PE or LSZH, applied under the armour .The nominal thickness is calculated by 0.02Du + 0.6mm where Du is the fictitious diameter under the sheath in mm. For cables without a lead sheath, the nominal separation sheath thickness shall not be less than 1.2mm. For cables where the separation sheath is applied over the lead sheath, the nominal separation sheath thickness shall not be less than 1.0mm.Lapped Bedding (for armoured lead sheathed cable): The lapped bedding consists of either impregnated/synthetic compounded paper tapes or a combination of two layers of these paper tapes followed by a few layers of compounded fabulous materials. The thickness is around 1.5mm.Armour (for armoured cable): The armour consists of round aluminium wire armour applied helically over an extruded separation sheath.Table 3. Round Armour Wire Diameter

Fictitious Diameter Under the Armour

Armour Wire Diameter

mm

mm

>

<< p=""><

-

10

0.8

10

15

1.25

15

25

1.6

25

35

2.0

35

60

2.5

60

-

3.15

Over Sheath: Overall sheath comprises a layer of extruded thermoplastic compound (PVC, PE or LSZH can be offered as an option.) or elastomeric compound (polychlorprene CSP or chlorosulfonated PE). The nominal oversheath thickness is calculated by 0.035D+1 where D is the fictitiuous diameter immediately under the oversheath in mm. For unarmoured cables and cables with the oversheath not applied over the armour, metallic screen or concentric conductor, the nominal oversheath thickness shall not be less than 1.4mm. And for cables with oversheath applied over the armour, metallic screen or concentric conductor, the nominal oversheath thickness shall not be less than 1.8mm.PHYSICAL PROPERTIES:Operating Temperature: up to 70°C (PVC insulation); up to 90°C (XLPE or EPR insulation)Temperature Range: -5°C ( PVC sheath ); -20°C ( PE sheath )Short Circuit Temperature( 5 seconds maximum duration ): 140-160°C (PVC insulation);250°C (XLPE or EPR insulation)Bending Radius: 12 x ODTable 4. Nominal /Operating /Testing Voltages

Rated Voltage Uo/U

Operating Voltage (Um)

Testing Voltage (rms)

1.8/3KV

3.6KV

6.5KV

3.6/6KV

7.2KV

12.5KV

6/10KV

12KV

21KV

8.7/15KV

17.5KV

30.5KV

12/20KV

24KV

42KV

18/30KV

36KV

63KV

21/35KV

42KV

73.5(53)*KV

26/35KV

42KV

91(65)*KV

*21/35KV and 26/35kV power frequency voltage test can be made under the following conditions: 2.5Uo x 30mins or 3.0Uo x 15mins. Numbers in brackets refer to the test values for 3.0Uo x 1.5mins.Single Core 1.8/3KV (Um=3.6KV) Dimensional Data

Nom. Cross-Section Area

Unarmoured Cables

Steel Wire Armoured Cables

Nom. Insulation Thickness

Copper Tape Thickness

Copper Wire Screen Area*

Nom. Sheath Thickness

Approx. Overall Diameter

Approx. Weight

Nom. Bedding Thickness

Armour Wire Size

Nom. Sheath Thickness

Approx. Overall Diameter

Approx. Weight

CU

AL

CU

AL

mm2

mm

mm

mm2

mm

mm

kg/km

mm

mm

mm

mm

kg/km

10

2.0

0.1

16

1.8

13

240

180

1.2

1.6

1.8

18

460

400

16

2.0

0.1

16

1.8

13

300

200

1.2

1.6

1.8

19

530

430

25

2.0

0.1

16

1.8

15

410

250

1.2

1.6

1.8

20

650

500

35

2.0

0.1

16

1.8

16

510

300

1.2

1.6

1.8

21

780

560

50

2.0

0.1

16

1.8

17

640

350

1.2

1.6

1.8

22

930

640

70

2.0

0.1

16

1.8

19

850

440

1.2

1.6

1.8

24

1170

750

95

2.0

0.1

16

1.8

20

1130

540

1.2

1.6

1.8

26

1460

870

120

2.0

0.1

16

1.8

22

1370

630

1.2

1.6

1.8

27

1730

990

150

2.0

0.1

25

1.8

23

1650

730

1.2

1.6

1.8

29

2030

1110

185

2.0

0.1

25

1.8

25

2010

860

1.2

1.6

1.9

30

2430

1280

240

2.0

0.1

25

1.8

27

2570

1050

1.2

1.6

2.0

33

3040

1530

300

2.0

0.1

25

1.8

29

3160

1250

1.2

2.0

2.1

36

3760

1860

400

2.0

0.1

35

1.9

33

3980

1560

1.2

2.0

2.2

39

4660

2230

500

2.2

0.1

35

2.1

35.5

4910

1905

1.3

2.5

2.5

43

5930

2930

630

2.4

0.1

35

2.2

39.7

6340

2420

1.4

2.5

2.6

49

7370

3430

800

2.6

0.1

50

2.3

44.5

7890

2980

1.4

2.5

2.7

52

9070

4230

1000

2.8

0.1

50

2.5

49.4

9890

3700

1.5

2.5

2.9

56

11100

4950

*Optional wire screen can be provided in combination of copper tapes. Nominal screen area, as stated in the table, can be supplied as standard.Electrical Data

Nom. Cross-Section Area

D C Resistance CU / AL

A C Resistance CU / AL

Short Circuit Rating of Conductor CU / AL1 sec

Capaci-tance

Charging Current

Short Circuit Rating of Copper Wire Screen1 sec

Short Circuit Rating of Copper Tape Screen1 sec

Reactance

Inductance

Impedance

Trefoil

Flat Spaced

Trefoil

Flat Spaced

Trefoil

Flat Spaced

cu

AL

cu

AL

mm2

μΩ/m

μΩm

kA

pF/m

mA/m

kA

kA

μΩ/m

nH/m

μΩ/ m

μΩ/ m

10

1830/3080

2330/3920

1.4/0.9

182

0.27

2.6

0.2

151

201

384

558

2332

3846

2332

3840

16

1150/1910

1460/2420

2.2/1.4

201

0.29

2.6

0.3

140

193

362

546

1462

2411

1478

2420

25

727/1200

927/1538

3.6/2.3

222

0.32

2.6

0.3

131

185

345

535

936

1544

952

1554

35

524/868

668/1113

5.0/3.2

251

0.35

2.6

0.4

122

178

327

524

679

1121

695

1131

50

387/641

494/822

6.8/4.4

281

0.39

2.6

0.4

116

172

313

514

511

834

527

844

70

268/443

343/568

9.8/6.3

341

0.45

2.6

0.5

110

165

300

495

364

583

386

597

95

193/320

248/410

13.3/8.5

397

0.50

2.6

0.5

104

160

287

485

272

427

300

446

120

153/253

196/325

17.2/11.0

430

0.55

2.6

0.6

104

159

283

480

225

345

257

367

150

124/206

159/266

21.2/13.5

464

0.59

4.3

0.6

100

156

280

475

193

287

229

313

185

99.1/164

128/211

26.6/17.0

513

0.65

4.3

0.7

98

154

274

465

165

237

206

267

240

75.4/125

98/161

34.9/22.3

573

0.70

4.3

0.9

94

150

267

459

Other supplier products

All supplier products

Same products

|

|

PMMA VR Lens For Google Cardboard |

Seller: Jinhua Kaiyue Photoelectric Technology Co.,Ltd |

PMMA VR Lens For Google Cardboard,Double Convex Lens |

|

|

PMMA Double Convex Lens |

Seller: Jinhua Kaiyue Photoelectric Technology Co.,Ltd |

PMMA Double Convex Lens,Double Convex Lens |

|

|

6X21 PBinoculars |

Seller: Jinhua Kaiyue Photoelectric Technology Co.,Ltd |

6X21 PBinoculars,Porro Prism Binoculars |

|

|

Night Vision Binoculars |

Seller: Jinhua Kaiyue Photoelectric Technology Co.,Ltd |

Night Vision Binoculars,Porro Prism Binoculars |

|

|

10X25 High Power Binoculars |

Seller: Jinhua Kaiyue Photoelectric Technology Co.,Ltd |

10X25 High Power Binoculars,Binoculars & Scopes |