PCB Wholesale Printed Circuit Board

Welcome to the world of Printed Circuit Board (PCB) technology from the GOLDEN TRIANGLE GROUP, one of the most professional printed circuit board China suppliers. PCB technology is an essential component of the ever-changing electronics industry. It is the foundation for modern electronics, allowing for faster, smaller, and more reliable electronic products.

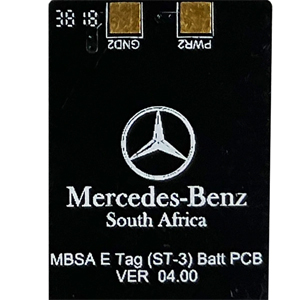

At GOLDEN TRIANGLE GROUP, we are committed to providing our customers with the best PCB OEM products available. Our custom printed circuit boards are designed to meet the highest standards of quality, performance, and reliability. We understand that PCBs are critical components in modern electronics and strive to ensure that our China PCB boards meet the needs of our customers.

As a leading China pcb board factory, GOLDEN TRIANGLE GROUP with strong PCB capabilities offers a variety of Printed Circuit Board products, ranging from single-sided boards to multi-layer boards. Our PCB ODM products are designed to meet a wide range of customer needs, from low-cost, single-layer boards to high-end, multi-layer boards. We also offer custom PCB fabrication designs to meet the specific requirements of our customers.

smt printed circuit board provide many advantages over traditional wiring and soldering. PCBs are cost-effective, easy to manufacture and maintain, and provide a much higher level of reliability than traditional wiring and soldering. Additionally, China PCB board can be used in a variety of applications, from consumer electronics to aerospace and medical equipment.

At GOLDEN TRIANGLE GROUP, we understand the importance of Printed Circuit Board technology and strive to provide our customers with the best fabrication board products available. We are committed to providing the highest quality PCBs including rigid PCB board, flex PCBs, and HDI circuit boards available, backed by our reliable customer service. We look forward to working with you to create the best PCBs available.

Printed Circuit Board Manufacturing Process

PCBs are the foundation of modern electronics and are the backbone of our digital world. They are used in almost all electronic devices, from the simplest of toys to the most complex of medical devices.

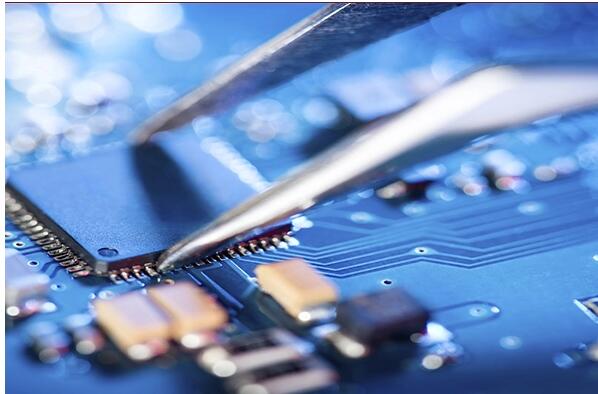

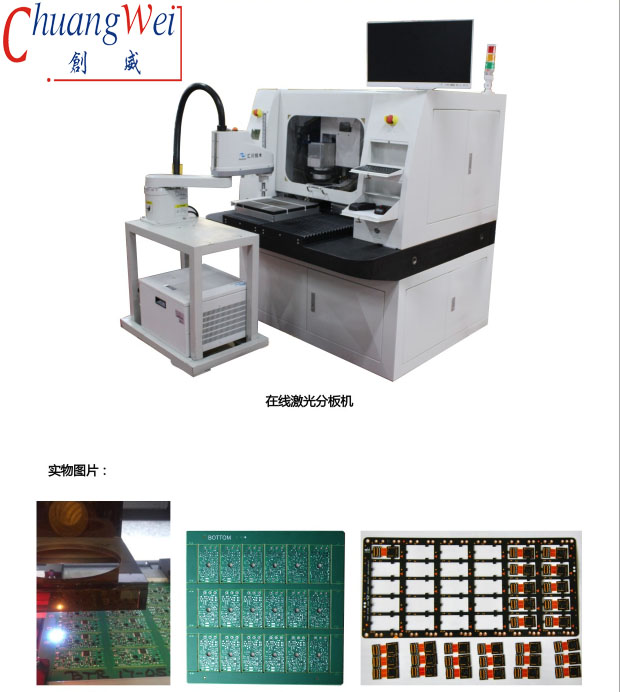

The smt control board manufacturing process is what makes PCBs possible. Without it, our world of electronics would look very different. This process involves a complex series of steps that must be followed in order to create a functional PCB. From design to assembly, each step is essential to ensure the highest quality product. The first step in the PCB manufacturing process is designing the fabrication board. This requires careful consideration of the features and components that will be present on the board, as well as the layout and design of the board itself. Once the design has been finalized, the PCB can be sent to the manufacturer for fabrication. During fabrication, the PCB is created using a combination of chemical and mechanical processes. This includes etching, drilling, and plating, as well as surface-mount technology. After fabrication, the PCB is ready for testing and assembly.

PCBs are essential for modern electronics, and the Printed Circuit Board manufacturing process is what makes them possible. As a smt pcb manufacturer, We hope you find the information on this page helpful and understand the importance of the PCB manufacturing process.

SMT Printed Circuit Board Main Purpose

A PCB is a very important component of electronic devices. It is a physical printed circuit fabrication board that is composed of layers of copper foil and other materials. The copper foil on a PCB serves as the main conductor and allows electrical signals to flow through the board. PCBs are used in a wide variety of electronic devices, from computers and s to TVs and gaming consoles.

The main purpose of a PCB is to provide an electrical connection between the various components of an electronic device. By connecting all of the components together, the device can function properly. The PCB also provides a way for the components to be organized and spaced out evenly. Without a PCB, all of the components would be jumbled together and the device would not be able to

For more information about pcb making service and pcb layout drawing, please feel free to contact us!

Send product request

Other supplier products

| PCBA Components Assembly | PCBA parts Assembly is a process of connecting components to a Printed Circuit Board (PCB) to form a functioning electronic device. It involves sol... | |

| SMT Printed Circuit Board Assembly | china smd assembly and manufacturing is the process of connecting components to a printed circuit board (PCB) to create an electrically functional ... | |

| Types of PCB Capabilities | PCB (printed circuit board) capabilities refer to the technology and processes that are used to manufacture printed circuit boards. This includes p... | |

| Flex PCB Solder Mask Black Silkscreen White | Flexible printed circuit boards (Flex PCBs) are a type of smallPCBthat use flexible and bendable materials for their substrate. These substrates ar... | |

| 2-Layers Rigid PCB White Silkscreen | Rigid PCBs are printed circuit boards with a solid substrate, usually made from fiberglass or epoxy. They are the most commonly used type of PCBs a... |