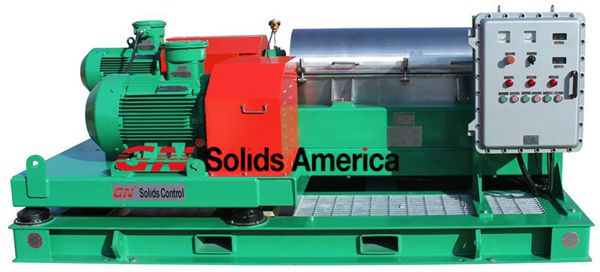

Decanter Centrifuge

GNLW means horizontal spiral type which is a normal model of decanting centrifuge GN Solids.Decanter Centrifugeis the last stage equipment in drilling mud system for solids control and mud cleaning. The superiority of Decanting Centrifuge is embodied in the solids processing size. Decanter Centrifuge could remove the solid particles with size 2-7 microns using the principle of centrifugal action, it is an ideal choice for separating particles in drilling mud. Always there is a screw pump or submersible pump to feed the mud to Decanter Centrifuge. After the drilling fluids being fed into the centrifuge drum, under the function of centrifugal force, solid phase particles are pushed to the internal wall of the drum, then to the solid discharge export of the small end of the drum and excreted. While the fluids is excreted from the overflow hole of the large end. Such cycle is to achieve the purpose of continuous separation. High speed decanting centrifuge are more effective for separation of fine solids.

High Configuration Decanter Centrifuge Features:

- Patent Design with the highest configuration and best material for long and reliable service.

- Decanter Centrifuge Bowl Cylindrical and Conical section made from Duplex Stainless Steel 2205 by centrifugalcasting.

- Centrifuge Other Parts of the bowl assembly material: stainless steel SS316L.

- Screw protection: Tungsten Carbide Tiles for longer life and easier replacement.

- Centrifuge Screw flow distribution port and bowl solids discharge port protected by tungsten carbide alloy.

- Easily adjustable liquid discharge weir height for flexible decantrer centrifuge application.

- Bowl assembly supported by tighten belt for protection of bearing in moving.

- Pressurized EX Proof VFD control cabinet with PLC controlled.

- Genuine SKF bearing for longer and reliable operation

Economic Configuration Decanter Centrifuge Features:

- Patent Design with the economic configuration for the centrifuge

- Centrifuge Bowl Cylindrical and Conical section made from Duplex Stainless Steel 2205 by centrifugal casting or SS 304 Material

- Other Parts of the bowl assembly material: stainless steel SS304.

- Screw protection: Ceramic Tiles for longer life and easier replacement.

- Screw flow distribution port and bowl solids discharge port protected bytungsten carbide alloy.

- Easily adjustable liquid discharge weir height for flexible application.

- Bowl assembly supported by tighten belt for protection of bearing in moving.

- Pressurized EX Proof VFD control cabinet for the centrifuge

- Decanter Centrifuge with Genuine NSK/FAG bearing

Decanter Centrifuge for Drilling Mud Solids Control System:

Decanter centrifuge is the final processing units in the arrangement of solids control equipment. It could be used to process unweighted and weighted, water-based and oil-based drilling fluids (muds).

On oilfield, middle speed centrifuge is used to recycle the barite and bentonite in solids control system, high speed decanter centrifuge could separate the fine solids in drilling mud after the desilter unit. Meanwhile, high speed centrifuge centrifuge is always applied in drilling waste management to recover the valuable drilling fluids. Typically, oilfield decanting centrifuge is preceded by gas busters, gumbo removal equipment (if utilized), shale shakers, mud Cleaners (if utilized), Vacuum degassers and hyrdocyclones.

GN Solids America, your reliable supplier for drilling mud Decanter Centrifuge.

Send product request

Other supplier products

| Vacuum Degasser | Vacuum Degasser GN ZCQ Vacuum Degasser Dicription GNZCQ seriesVacuum Degasseris adapted to get rid of various cut-in gases in the drilling fluids.... | |

| Centrifugal Pump | Centrifugal Pump Long-life mechanical seal Thick, strong, concentric casing Famous brand bearing Open impeller design, lower axial thrust loads, e... | |

| Mud Agitator | Mud Agitator GNJBQ Mud Agitator Discription: GN Mud agitator JBQ series mud Agitator, Less than 5.5 kW drilling mud Agitator adopts the blender cyc... | |

| Mud Cleaner | GNZJ Mud Cleaner Description GNZJMud Cleaneris the second stage and the third stagesolids control equipmentwhich is a combination of Desander, Desi... | |

| Shale Shaker | Shale Shaker GNZS Linear Motion Shale Shaker Features & Benefits: Ajustable High G force for primarysolids controlor cuttings drying. Heat tr... |