Zinc Alloy Casting Washing Machine Spare Part

Product Description Product nameZinc Alloy Casting Washing Machine Spare PartProcess MethodDie castingMaterial:Zinc Alloy 8#FinishPearl Chrome PlatedColorSilverDimension470x270x85mmShapeIrregularCavity1Production ProcessDie casting,Website:, deburring , CNC machining, Drill&tapping, Chrome plated , full inspection and packing.ApplicationWashing machineCustomizeOEMTooling lead time35 working daysMass production lead time25 working daysMOQ/batch200pcsPackingSeparate Packing, 4 pcs/carton, 30 cartons/palletTooling payment term50% in advance, balance after send the successful samplesMass order payment term30% deposit, 70% T/T before shipmentPrice termEXW, FOB, CIFFOB portShenzhen or HongkongPlace of originGuangdong, China.CertificationISO9001:2008Production Process Product PictureMore InformationAvailable Die Casting Material3#, 5#, 8# zinc alloyAvailable Surface TreatmentChrome plated, Zinc plated, Nickle Plated, PaintingSoftwarePro/E,UG, Solidwork, Auto CAD, PDFAdvantages1. Own factory2. We can provide competitive price.3.High precision, tolerance can be within ±0.02mm.4.We can also provide one stop service,including mould making, die casting, CNC machining, surface treatment and assembly.5. With individual working instruction instruction.6.With individual quality instruction.7.100% inspection before shipment.Confidential service1.Your information is confidential.2.Your drawings are confidential.3.Your products are only for you.Guarantee2 yearsQuality Control Management ItemQuestionAnswer1.1Is there quality control on all production lines?Yes, all production lines have adequate quality control.1.2Do the QA/QC inspectors work independently from the production line?Yes1.3Who does the QC/QA Manager / Supervisor report to?Yes1.4How many QA/QC inspectors in total?Yes1.5Does the company prepare all of the necessary working instruction and inspection instruction before the mass production start?Yes1.6Does the Working instruction contain all of the requirements from customer?Yes1.7Does the worker been trained by the working instruction?YesAfter Sales Service ItemQuestionAnswer1.1Is customer feedback including complaints, clearly recorded and maintained?Yes, with a standard feedback form and records.1.2Are there any clear procedures for handling customer complaints?Yes, with clear procedures and written records1.3Is there a closed-loop corrective action system in place?Yes1.4Can finished/packaged products be traced by lot identification to the appropriate raw material test reports?Yes, with procedures to trace raw materials.

Other supplier products

|

|

Black Chrome Plating Die Casting Led Heatsink |

Product Description Product nameBlack chrome plating die casting led heatsinkProcess MethodDie castingMaterial:Zinc Alloy 5#FinishBlack Chrome Plat... |

|

|

Die Casting Aluminum Electric Motor Spare Part |

Product Description Product namedie casting aluminum electric motor spare partProcess MethodDie castingMaterial:Aluminum Alloy ADC12FinishPaintedCo... |

|

|

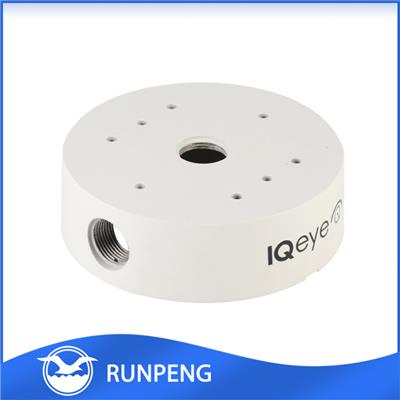

OEM Aluminum Die Casting Camera Housing |

Product Description Product nameOEM Aluminum Die Casting Camera HousingProcess MethodDie castingMaterial:Aluminum Alloy ADC12FinishPowder CoatedCol... |

|

|

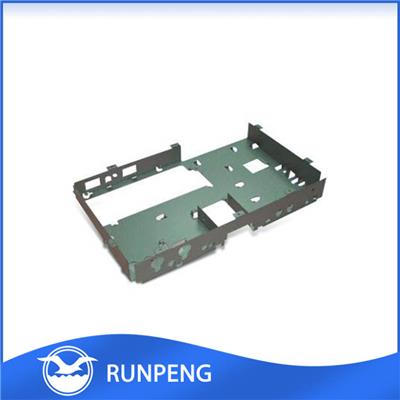

Zintec Stamping Power Box |

Product Description Product nameZintec Stamping power boxProcess MethodStampingMaterial:Galvanized sheetFinishNaturalColorNaturalDimension290x130x2... |

|

|

Aluminum Stamping Electronic Case |

Product Description Product namealuminum stamping electronic caseProcess MethodStampingMaterial:AluminumFinishPowder CoatedColorSilverDimension580x... |

All supplier products

Same products

|

|

INTERFLON Food 2 Grease for the lubrication of foodstuff machines 400ml |

Seller: Dongguan Fuxiaojing New Materials Technology Co., Ltd |

Intended for the general lubrication of machine parts with slow to medium-fast movements and ligh... |

|

|

YAMADA MMG-80 MP 85ml for Bearing Sliding Parts |

Seller: Dongguan Fuxiaojing New Materials Technology Co., Ltd |

It is a heat-resistant, extreme pressure, water resistant, durable, lithium soap universal grease |

|

|

Mobil Grease Unirex N3 for High-Temperature Service in Rolling-Element Bearings |

Seller: Dongguan Fuxiaojing New Materials Technology Co., Ltd |

The Mobil Unirex N 3 Bearing Greaseprovides exceptional performance |

|

|

Double Column PV Mounting |

Seller: Taizhou Dongsheng New Energy Technology Co., Ltd. |

Double Column PV Mounting adopts a symmetrical double column structure, and the overall rigidity ... |

|

|

Coltri oil ST 755 Fully Synthetic compressor oil 1L Food Grade lubrication |

Seller: Dongguan Fuxiaojing New Materials Technology Co., Ltd |

COLTRI OIL ST 755 is a fully synthetic oil specifically developed for long durations of process g... |