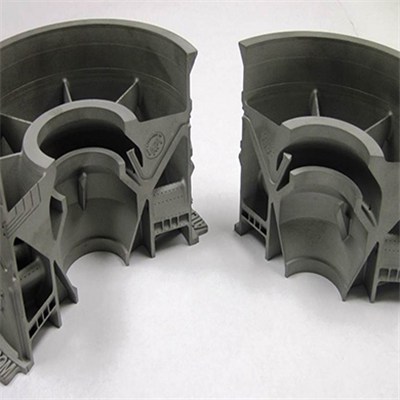

CNC Prototyping

Product Details:The main purpose for prototyping a design is to check whether it work mechanically or look as good as what was rendered on the computer screen. The best way to confirm the design is to make plastic and metal prototypes using real production materials rather than simulants. This makes CNC prototyping a far superior process when compared to popular processes such as SLA and 3D printing. We can machine hardened tool steel up to 1.7 m in length.We have a wide range of common production and engineering plastic materials available: POM (Delrin),Website:, ABS, polycarbonate (PC), PC/ABS, PBT, nylon 6 (PA 6), PA+30%GF, PC+30%GF, HDPE, PE, PEEK, PF, Acrylic (PMMA), polypropylene (PP), PP+20%GF, PVC. (contact us for more info on available plastics).Tasuns have a lot of experience machining the following metals: Titanium, stainless steels, brass, copper, bronze, steel, tooling steel, aluminium alloys (wide range available), zinc and magnesium.With our 24 hour CNC department we offer the fastest lead times in the industry guaranteed – as quick as 1 day from order to shipping.Advantages of CNC prototyping and production:1) High precision and repeatability can be achieved2) Low production start up costs for low volume production. Due to low machine rates CNC can more viable than injection molding.3) Fast lead times compared to casting and injection molding4) Use real production representative material rather than simulant material use by alternate prototyping methods (i.e. 3D printing, SLA, SLS etc.)5) Easily change or improve your designs without the need for expensive and time consuming mold modifications.To Customers: Dear Friends, That is very honor that you find our website!In order to fast efficient reply your requirements, please send us your RFQ to . Please also advice detail requirement like surface, quantities and tolerance. You can surely get reply within 24 hours!Best regards,Shenzhen Tasuns Industry Ltd.

Other supplier products

|

|

Brass Connectors |

Product Details:

Material Acceptable

... |

|

|

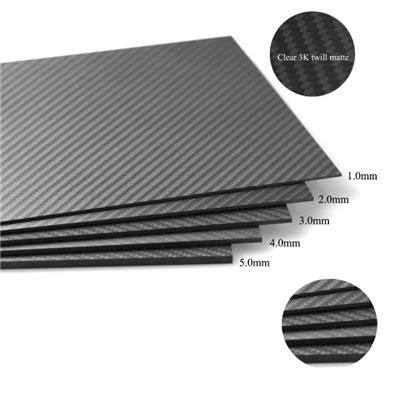

100% Carbon Fiber Plates |

Product Details: Place of Origin:ChinaSupply Type:Make-to-OrderRaw Material:Carbon Fiber Fabric&Epoxy ResinWeave:Twill/Plain/UDType:1K, 1.5K,3K,6K,... |

|

|

Precision Sheet Metal Product with Good Quality |

Basic InfoModel NO.: LFAL0146Certification: ISO9001Customized: CustomizedApplication: Metal Cutting Machine,Website:, Metal Straightening Machinery... |

|

|

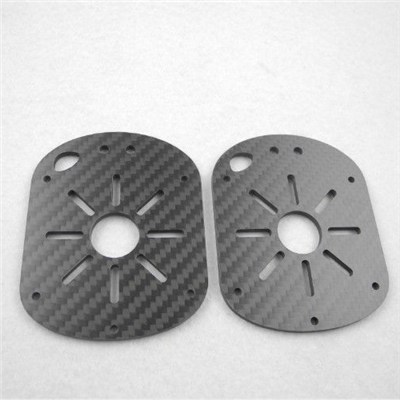

High precision cnc machining carbon fiber plate |

Product Details: Place of Origin:ChinaSupply Type:Make-to-OrderRaw Material:Carbon Fiber Fabric&Epoxy ResinWeave:Twill/Plain/UDType:1K, 1.5K,3K,6K,... |

|

|

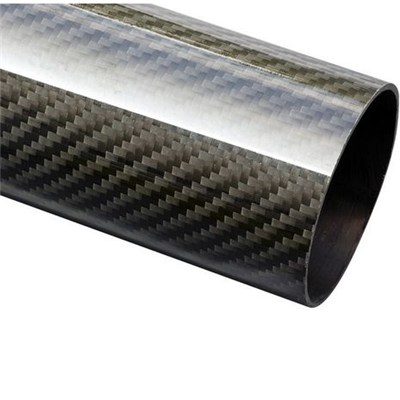

Twill Carbon Fiber Round Tube |

Product Details:Material:100% carbon fiberOuter Diameter:as your requestInner Diameter :as your requestLength:as your request (the regular model le... |

All supplier products

Same products

|

|

INTERFLON Food 2 Grease for the lubrication of foodstuff machines 400ml |

Seller: Dongguan Fuxiaojing New Materials Technology Co., Ltd |

Intended for the general lubrication of machine parts with slow to medium-fast movements and ligh... |

|

|

YAMADA MMG-80 MP 85ml for Bearing Sliding Parts |

Seller: Dongguan Fuxiaojing New Materials Technology Co., Ltd |

It is a heat-resistant, extreme pressure, water resistant, durable, lithium soap universal grease |

|

|

Mobil Grease Unirex N3 for High-Temperature Service in Rolling-Element Bearings |

Seller: Dongguan Fuxiaojing New Materials Technology Co., Ltd |

The Mobil Unirex N 3 Bearing Greaseprovides exceptional performance |

|

|

Double Column PV Mounting |

Seller: Taizhou Dongsheng New Energy Technology Co., Ltd. |

Double Column PV Mounting adopts a symmetrical double column structure, and the overall rigidity ... |

|

|

Coltri oil ST 755 Fully Synthetic compressor oil 1L Food Grade lubrication |

Seller: Dongguan Fuxiaojing New Materials Technology Co., Ltd |

COLTRI OIL ST 755 is a fully synthetic oil specifically developed for long durations of process g... |