Metal Scrap Briquetting Press

Brief introduction of metal scrap briquetting pressMetal scrap briquetting press is a kind of equipment which can press all kinds of metal scrap/metal filing/metal chips or metal powder such as scrap iron,Website:, iron powder, sponge iron, copper scale/copper filings, copper powder, aluminum scraps, aluminum powder etc into high density cylinder/square/rectangle blocks/briquettes without any adhesives added. The finished briquettes compressed by briquetting press are with high density, high strength, widely used in metallurgy, chemical industry etc. Not only easy to transport, but also take full advantages of resources, with good economic benefit and social benefit. It’s a wonderful energy saving and environmental protection equipment. Zhengke metal scrap briquetting press has been sold throughout China and the world, such as Shanxi coking group, Hebei Yuanbaoshan steel mill, Indian customers, Oman customers etc. All are in normal use, enjoyed good reputation from customers.Metal scrap briquetting press made by Zhengke has passed the inspection of Henan Quality Supervision Bureau, ISO9001 international quality management system certification, CE certificate standard, Russian GOST certificate etc. Meanwhile, we had applied many patents of scrap iron/iron powder briquetting press to State Patent Office and were well-known in metal scrap briquetting industry.Function of metal scrap briquetting pressMetal scrap briquetting press made by Zhengzhou Kehua Industrial Equipment CO., Ltd can be used for compressing all kinds of metal scrap such as iron scrap, sponge iron, copper filings, and aluminum scrap into blocks/briquettes without any adhesives added. The whole production process doesn’t need to heat, doping or other process, directly cold pressing molding, molding as well as to ensure that the original material of the same, so that the storage, transportation and recycling for furnace. It can be equipped with automatic screw feeder, chain type automatic discharging device according to user's situation, reduces the labor intensity of workers.Features of Zhengke metal scrap briquetting press1. Metal scrap briquetting press is specially designed with advanced hydraulic transmission technology, used of high quality wear-resistant oil seal, oil cylinder is used the latest domestic high-tech craft processing and assembly, thus ensuring continuous operation, don’t abate oil cylinder pressure, durable and smooth operation;2. Energy saving & environmental protection, no pollution, no noiseZhengke metal scrap briquetting press is mainly used to press industrial waste and dust into regular shaped briquettes for further usage, reducing dust pollution and improving resource utilization ratio. Meanwhile, metal scrap briquetting press is adopted special design in mechanical structure and power control; it can run in low power, it is a favorable energy conservation and environmental protection equipment. The metal scrap briquetting press produced by Zhengke is adopted enclosed structure design, during briquetting; there is no pollution and noise.3. Wide application and low requirement for working environmentZhengke metal scrap briquetting press is suitable for use in all countries around the world. According to different conditions of every country, metal scrap briquetting press can be reasonable adjusted for normal use, such as voltage, engineering design requirements, geographical conditions etc.Additionally, metal scrap briquetting press can be normally used in all kinds of severe environment, such as extremely cold weather, high temperature, plateau etc.4. Easy installation without foundation and simple transportationZhengke metal scrap briquetting press is designed with high strength steel plate as its support, enabling it to be directly used on hard flat area without foundation, there is no vibration during working; in addition, it is easy for users to transfer and transport this equipment.5. Few employing, simple operation and easy maintenanceThe metal scrap briquetting press can be designed with semi-automatic and full automatic based on customer’s requirements, thus ensuring less labor and simple operation. In daily use, you only need to do regular maintenance according to the maintenance instruction, it is very convenient to maintain.6. High safetyAll of drive parts of Zhengke metal scrap briquetting press such as drive shaft, gear, electric motor, belt pulley etc. are adopted enclosed or semi-enclosed design in strict accordance with the equipment safety standards, and it is outfitted with an observation table and hole on this machine, thereby ensuring equipment safety and personal safety.Main technical parameters:ModelBriquette's size

(mm)Briquette's density

(T/M3)Briquette's weight

(KG)Power

(KW)Capacity

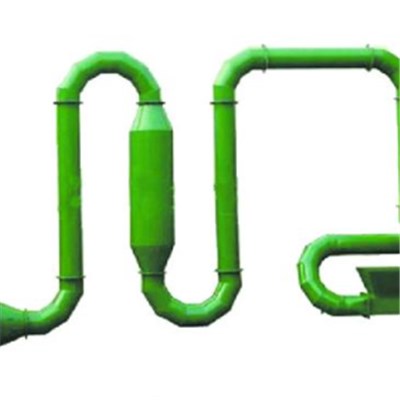

(Pcs/min)Operation MethodZK32-200Φ80-1004.0-5.22-3112-3Computer controlZK32-300Φ100-1204.2-5.ZK32-400Φ110-1404.2-5.ZK32-500Φ120-1504.5-5.55-8303-5ZK32-600Φ130-1604.5-5.ZK32-700Φ140-1604.6-5.58-10373-4Note: The density and weight of briquettes are vary with different raw materials.Metal scrap briquetting press production line process flow chart

Other supplier products

|

|

Hydraulic Briquetting Machine |

Introduction of Hydraulic Briquetting MachineHydraulic briquetting machine is a kind of mechanical equipment which can be used for converting powde... |

|

|

Hot Airflow Dryer |

Hot Airflow DryerHot Airflow Dryer also called pipeline type drier,Website:, Its one of the important equipment production mechanism charcoal.adopt... |

|

|

Coke Briquetting Press |

Brief introduction of coke briquetting pressCoke briquetting press is a kind of equipment which can press the coke powder,Website:, coke breeze, co... |

|

|

Mesh Belt Dryer |

Mesh belt dryer instructionMesh belt dryer is a batch type,Website:, continuously working drying equipment. Mesh belt dryer is usually used to dry ... |

|

|

Jaw Crusher |

Jaw Crusher Jaw crusher is one of the most popular crushing equiepments in the international market at present,Website:, which is mainly used for m... |

All supplier products

Same products

|

|

INTERFLON Food 2 Grease for the lubrication of foodstuff machines 400ml |

Seller: Dongguan Fuxiaojing New Materials Technology Co., Ltd |

Intended for the general lubrication of machine parts with slow to medium-fast movements and ligh... |

|

|

YAMADA MMG-80 MP 85ml for Bearing Sliding Parts |

Seller: Dongguan Fuxiaojing New Materials Technology Co., Ltd |

It is a heat-resistant, extreme pressure, water resistant, durable, lithium soap universal grease |

|

|

Mobil Grease Unirex N3 for High-Temperature Service in Rolling-Element Bearings |

Seller: Dongguan Fuxiaojing New Materials Technology Co., Ltd |

The Mobil Unirex N 3 Bearing Greaseprovides exceptional performance |

|

|

Double Column PV Mounting |

Seller: Taizhou Dongsheng New Energy Technology Co., Ltd. |

Double Column PV Mounting adopts a symmetrical double column structure, and the overall rigidity ... |

|

|

Coltri oil ST 755 Fully Synthetic compressor oil 1L Food Grade lubrication |

Seller: Dongguan Fuxiaojing New Materials Technology Co., Ltd |

COLTRI OIL ST 755 is a fully synthetic oil specifically developed for long durations of process g... |