Shelf Rack Machine

The profile drawing for shelf rack machineThe thickness of Material: 1.5-2.5mm Working flow of shelf rack machine: uncoiler—Leveling—Punching--roll forming--- hydraulic cut to length—output table Main Specification of shelf rack machine

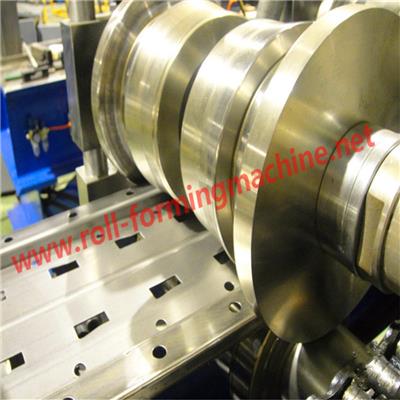

1) Main roll forming system

Main motor power: 18.5kw

Drive: Double Chain 1.2"

Main shaft dia: ¢76mm material: 45﹟forge steel and quenched

Roller material: Gcr5 bearing steel and quench treatment 58-62,Website:, chrome coated 0.05mm

Roll station:18 groups

Raw material: 1.5mm

Working speed: 0m--15m/min(include Punching time)

Coder: Omron

PLC: YASKAWA, made in Japan. 380V 50HZ

Computer operating panel: touching screen 5) Motor punching and hydraulic cutting

Hydraulic power: 5.5KW

Material of punching mould and cutting blade: Cr12,quenched 58°-62°

Working pressure:20mpa

Punching motor: 5.5KW

Punching frequency: 50/min

Power of Servo motor: 2.2KWEquipment list for shelf rack machine: NO.ProductQuant.15T Manual uncoiler12Separate Motor punching machine13Main Roll forming(cutting, PLC computer, Hydraulic system)14Output table(Freely)2Detailed information Terms of payment: 30%T/T ,Balance to be paid before shipping after inspection Deliver time: 60days after get 30% down payment Warranty: 1 year warranty from date of shipment Guarantee:

● Engineer will give free training lessons to labors in buyer’s factory.

● The Buyer will buy the round-trip air ticket for Engineer if visa application is approved. The buyer is also responsible to bear expenses generated, e.g. visa formalities, meals, accommodation and allowance of USD50 for engineer.

● During this guarantee period, we will provide spare parts without any charge in case of quality discrepancy caused by us. If the malfunctions are caused by your incorrect operations, we will provide the buyer spare parts at cost price.

● We will charge the buyer cost price of spare parts beyond one year and provide long-term technical guide.Photos for shelf rack machine: CertificatesExhibition

After sales service:

1).Engineer will give free training lessons to labors in buyer’s factory.

2).The Buyer will buy the round-trip air ticket for Engineer if visa application is approved.

3).The buyer is also responsible to bear expenses generated, e.g. visa formalities, meals, accommodation and allowance of USD80 for engineer per day.

4).During this guarantee period, we will provide spare parts without any charge in case of quality discrepancy caused by us. If the malfunctions are caused by your incorrect operations, we will provide the buyer spare parts at cost price.

5).We will charge the buyer cost price of spare parts beyond one year and provide long-term technical guide.

Other supplier products

All supplier products

Same products

|

|

INTERFLON Food 2 Grease for the lubrication of foodstuff machines 400ml |

Seller: Dongguan Fuxiaojing New Materials Technology Co., Ltd |

Intended for the general lubrication of machine parts with slow to medium-fast movements and ligh... |

|

|

YAMADA MMG-80 MP 85ml for Bearing Sliding Parts |

Seller: Dongguan Fuxiaojing New Materials Technology Co., Ltd |

It is a heat-resistant, extreme pressure, water resistant, durable, lithium soap universal grease |

|

|

Mobil Grease Unirex N3 for High-Temperature Service in Rolling-Element Bearings |

Seller: Dongguan Fuxiaojing New Materials Technology Co., Ltd |

The Mobil Unirex N 3 Bearing Greaseprovides exceptional performance |

|

|

Double Column PV Mounting |

Seller: Taizhou Dongsheng New Energy Technology Co., Ltd. |

Double Column PV Mounting adopts a symmetrical double column structure, and the overall rigidity ... |

|

|

Coltri oil ST 755 Fully Synthetic compressor oil 1L Food Grade lubrication |

Seller: Dongguan Fuxiaojing New Materials Technology Co., Ltd |

COLTRI OIL ST 755 is a fully synthetic oil specifically developed for long durations of process g... |