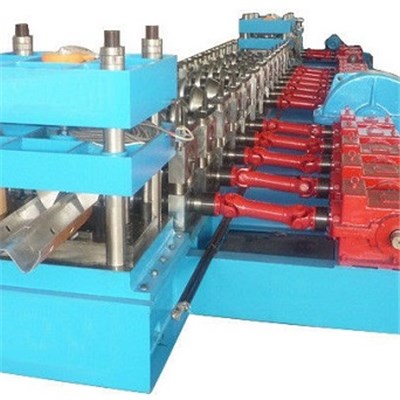

Two Waves W Beam Roll Forming Machine

Working flow:Decoiler-----feeding----- leveling and guiding ------roll forming ------ punching-----cutting----output table Machine components:

No.

Name

Qty

1.

De-coiler

1 Set

2.

Feeding and Guiding Device

1 Set

3.

Roll Forming Machine

1 Set

4.

Punching device

1 Set

5.

Hydraulic Cutting Device

1 Set

6.

PLC Control Box

1 Set

7.

Output table

1 Set

Technical description:

Decoiler

Type

Manual decoiler

Bearing capacity

5T

Inner diameter

508-600mm

Outer diameter

1200mm

Leveler device

Number o leveling rollers

7 (with 2 guiding rollers)

Leveling roller diameter

100mm

Roller material

45# steel polished and coated with chrome HRC55-60°

Hydraulic punching machine

Hydrauilc pump power

11kw (share with cutter)

Punching moulds

Cr12 material, quenching HRC55-60°

Cold roll forming machine

Roll forming stations

according to customers'sectional profiles

Roller material

GCr15, precision machining, polishing and quenching HRC 55-60

Shaft diameter

90mm

Shaft material

high grade forge 45# steel, heat treatment

Driven

1.5"chain

Main power

18.5KW AC motor

Length error

±2mm

Hydraulic cutter

Cutting length control way

PLC ,computer counter

Cutting tolerance

±2mm

Cutting mould material

Cr12, quenching HRC 55-62

Control system

Type

PLC Frequency Control System with touch screen

PLC brand

Japan Panasonic

Encoder Brand

Omron

Our ServicesTermsPayment type: 30% T/T prepaid and balance should be paid before loadingDelivery time: 40days after receiving advance payment.Guarantee period: 18months free service/ pay service all the machine lifeInstallation and training:If buyers visit our factory and check the machine, we will teach you how to install and use the machine, and also train your workers/technician face to face.Without visiting,we will send you user manual and video to teach you to install and operate.If buyer needs our technician to go to your local factory,please arrange board and lodging and other necessary things.

We can produce machine as different profile drawing.Advantages

1.We are factory and located in Shanghai,China,offer best quality machines

2. Customers Design ,Size,Color&Logo are accepted.3. With20 years professional manufacture experience4. Prompt Delivery&Competitive Price5. Main markets:Middle East, Europe, North America, Africa,Southeast Asia.

We can produce machine as different profile drawing.

FAQWHY CHOOSE AOFA COMPANY1) Q: Do you have after sales support? A: Yes, we are happy to give advice and we also have skilled technicians available across the world. We need your machines running in order to keep your business running. 2) Q: How do your machines compare with other big companies in this market? A: We are up to date with the latest technology and improve our machines accordingly 3) Q: Will you deliver the right goods as ordered? How can I trust you? A: Yes, we will. The core of our company culture is honesty and credit. AOFA is ALIBAB's Gold supplier with BV assessment and CE certificate. 4) Q: What can you do if the machine broken? A: Our machine's warranty period is 18months,if the broken parts can't repair,we can send the new parts replace the broken parts freell,but you need pay the express cost yourself.if after warranty period,we can through negotiationfor to solve the problems,and we supply the technical support for the whole life of the equipment. 5) Q: Can you be responsible for transport? A: Yes,please tell me the destination port or address.we have rich experience in transport. 6) Q: Can you supply the raw materials? A: Yes,we can supply the galvanized steel coil,galvalume steel coil,color steel coil,and aluminum coil.

Other supplier products

|

|

UBM K Span Roll Forming Machine |

TechnicalSize: 9000mm × 2250mm × 2300mmTotal Weight: about 11000KGMain Motor Power: 18.5KW forming power is 7.5kw ; bending power is 4.0kw;cu... |

|

|

Ladder Type Cable Tray Roll Forming Machine |

Working flow:Decoiler-----feeding and guiding----- leveling ------roll forming -----punching------ cutting----output

Machine components:... |

|

|

Seaming Type K Span Roll Forming Machine |

TechnicalSize: 9000mm × 2250mm × 2300mmTotal Weight: about 11000KGMain Motor Power: 18.5KW forming power is 7.5kw ; bending power is 4.0kw;cu... |

|

|

Three Waves W Beam Roll Forming Machine |

Working flow:Decoiler-----feeding----- leveling and guiding ------roll forming ------ punching-----cutting----output table Machine components:No.N... |

|

|

Conner Roll Forming Machine |

Working flow:Decoiler-----feeding------roll forming ------ punching-----cutting----output tableMachine components:No.NameQty1.De-coiler1 Set2.Roll ... |

All supplier products

Same products

|

|

INTERFLON Food 2 Grease for the lubrication of foodstuff machines 400ml |

Seller: Dongguan Fuxiaojing New Materials Technology Co., Ltd |

Intended for the general lubrication of machine parts with slow to medium-fast movements and ligh... |

|

|

YAMADA MMG-80 MP 85ml for Bearing Sliding Parts |

Seller: Dongguan Fuxiaojing New Materials Technology Co., Ltd |

It is a heat-resistant, extreme pressure, water resistant, durable, lithium soap universal grease |

|

|

Mobil Grease Unirex N3 for High-Temperature Service in Rolling-Element Bearings |

Seller: Dongguan Fuxiaojing New Materials Technology Co., Ltd |

The Mobil Unirex N 3 Bearing Greaseprovides exceptional performance |

|

|

Double Column PV Mounting |

Seller: Taizhou Dongsheng New Energy Technology Co., Ltd. |

Double Column PV Mounting adopts a symmetrical double column structure, and the overall rigidity ... |

|

|

Coltri oil ST 755 Fully Synthetic compressor oil 1L Food Grade lubrication |

Seller: Dongguan Fuxiaojing New Materials Technology Co., Ltd |

COLTRI OIL ST 755 is a fully synthetic oil specifically developed for long durations of process g... |