RYKM High Speed Four Colors Flexo Printing And Slotting And Die-cutting And Stacker Machine

Cangzhou ROYAL Packing Machinery Co.,Ltd is one of the leading China rykm high speed four colors flexo printing and slotting and die-cutting and stacker machine manufacturers,Website:, welcome to wholesale cheap rykm high speed four colors flexo printing and slotting and die-cutting and stacker machine from our factory.Some Printing samples: TECHNICDETAILSMachine introduction:1.This machine is component with the feeding unit, printing unit, slotting unit, rotary die-cutting unit and stacker, can accomplish the process of the corrugate paperboard printing, slotting and die-cutting.2.The materials of the body is HT250,thickness of body is 60mm,after second stage annealing ,making by CNC machine,with high strength and high precision.3.All the transmission gear is spiral gear,with low noise and high precision,gears after high frequency heating and grinding,adopt automatic circle lubrication.4.The gear material is 20CrMnti alloy steel,after high frequency heating and grinding.and the main transmission gear and roller adopt expansion sleeve connection.5.Bearing adopt the famous brand made in China like HRB and WANXIANG.6.The mail motor adopt frequency converters adjust, the frequency is "Delta" brand made in Taiwan, the PLC also adopt "Delta" brand made in Taiwan, the contactor adopt "Seimens" brand.7.The rubber roller adopt Jizhou Chunfeng Yinxing rubber roller, famous brand in China.8.Anilox roller adopt "Haili" brand, famous brand in China.1.Cardboard feeding unit.⑴.Unit moving. ①.Each unit is electric moving left and right with warning bell. When unit moving, the bell will be warning to make sure the operator safe. The moving motor with constant torsional moment which can buffer the impact of the two units when the operation is wrong.②.After all the units closed, each part is pneumatic locked. There is also lead locked cylinder which can make each part locked with bottom-track lock. If the cylinder is not locked, the main motor will not work.⑵.Lead edge feed system.①.The Lead edge feed unit is made in Shanghai, with long life,and high precision for feeding.②.Wind absorbing auxiliary paperboard feeding, can make the cardboard feed favoringly. The volume of the wind can be adjusted accord the camber of the paperboard.③.Electric and PLC control the side baffles move left and right.electric control the behind baffles move back and front.The distance between the frontal baffles and the feed table is synchronous manual adjust.④.With colorful touch screen show the produce quatity and can be input the production plan and also show the produce sheets number. Once the plan is finished, the counter system stops the feeding part and warns.999 order can store in the touch screen.⑶.Dust clean.①.Brush dust-removal equipment with dust-absorption blower. This equipment can clear the dust on the surface of the cardboard,improve the printing quality.⑷.Cardboard feeding roller.①.The up cardboard feeding roller is steel tube without gaps,be covered with the hardwearing rubber, after balance correction.②.The down cardboard feeding roller is is steel tube without gaps,embossing and hard chromium plating, after balance correction.③.The distance between the up cardboard feeding roller and down cardboard feeding roller is adjusted by hands,while the dial show the adjust date,the adjusting scope is 2-12mm.The up and down feed roller adoptthe crosshead connect with the drive gears,when adjust the distance between the up and down rollers,the distance between the two driver gears of the up and down rollers will not changed.⑸."Automatic zero-returning" and "printing platecleaned memory" function.①.The feed unit, printing unit, slotting unit and die-cutting unit all have electric "Automatic zero-returning" and "printing platecleaned memory" function. ②Usually adjust the printing roller, slotting knife roller ,and die-cutting roller to the right printing location, it only need try to feed 2 sheets with use The "Automatic zero-returning" and "printing block cleaned memory" function. Decrease the cardboard waste.2.The printing Unit.⑴.The printing roller.①.The printing roller is steel material, after balance correction. ②.The surface of the printing roller is grinded, polished and hard chromium plating.③.The-printing-plate-reel structure is adopted. The pedal switch control the printing roller run clockwise and anticlockwise,makes change printing plate easy.④.A complete slot in the printing roller for hung the printing plate,the size of the slot is 9mm×3mm.⑵.The down press printing roller.①.The down press printing roller adopt steel tube without gaps, after balance correction.②.The surface of the down press printing roller is grinded, polished and hard chromium plating.③.The distance between the printing roller and down press printing roller is adjusted by hands,while the dial show the adjust date,the adjusting scope is 2-12mm.The printing and down press printing roller adopt the crosshead connect with the drive gears,when adjust the distance between the two rollers,the distance between the two driver gears of the two rollers will not changed.⑶.The anilox roller: ①.The material of the steel anilox roller is steel,usually chose 180#-250#.②.The steel anilox roller surface adopt advanced chromium plating.Smoothness and hard wearing.③.The ceramic roller is steel pipe cover with high hardness ceramic,with laser cutting the ink hole.④.The automatic Pneumatic control Up-down device of the anilox roller is synchronous with the cardboard feeding system.(when the cardboard is fed,the anilox roller is go down and touch the printing plate,when cardboard feeding is stop,the anilox roller will go up and separated from the printing plate.)The anilox roller also could be pneumatic controlled by manual button for up and down.⑷.The rubber roller.①.The rubber roller is steel roller covered with hardwearing rubber,this roller is especially grinded, after balance correction .the surface's diameter in middle part of rubber roller is bigger than two sides,so as to obtain good effect of ink transmission.⑸.The Up and down cardboard feeding roller.①.The diameter of the up cardboard feeding roller is 94mm,with four cardboard feed wheel . The up cardboard feeding roller is steel tube without gaps, been grinded, polished and hard chromium plating, and after balance correction.②.The down cardboard feeding roller is steel tube without gaps,been grinded, polished and hard chromium plating,and after balance correction.③.The distance between the up and down cardboard feeding roller is adjusted by hands,while the dial show the adjust date,the adjusting scope is 2-12mm.The up and down cardboard feeding roller adopt the crosshead connect with the drive gears,when adjust the distance between the two rollers,the distance between the two driver gears of the two rollers will not changed,it can make the machine have high printing precision,low noise,and the gears have longer useful time.⑹.The adjustive device of the printing roller.①.Adopt satellite gear structure for adjust the clockwise and the anticlockwise phase of the printing roller.②.The clockwise and the anticlockwise phase of the printing roller is adjusted by the PLC and electricity,360° could be adjusted while the machine running or stop.③.The horizontal move of the printing roller is adjusted by PLC and electricity, the adjusting distance is 10mm.④.The"Automatic zero-returning" and"printing plate cleaned memory" function can make the machine adjust the printing plate to the right printing location quickly.(The "Automatic zero-returning" function is for clear the print plate,when you use this function,the printing roller will automatic run to the best location which for wash the print plate, after finish washing, "printing plate cleaned memory" can make the print roller automatic return to the location before wash the printing plate,it will save time for adjust the print block again after clear printing plate)⑺.Inking system.①.Inking system adopts pneumatic diaphragm pump inking with the ink cup to prevent the ink splashing. Steady inking and easy to maintain.②.Have ink dust gauze,make the ink more clear,improve the printing effect.③.When the machine stop,the anilox roller and rubber roller could running independently for transmission ink and prevent the ink dry out.④.With ink sensor,while ink level lower or empty,the unit will warning for add ink,save wast paper.⑻.Fix system of the printing unit.①.Self-locking system is used in the distance adjustment of the feeding roller,down printing press roller,anilox roller and rubber roller.②.There is a device for fix the "printing clockwise and anticlockwise phase",a cylinder is used,when the unit is opened and when the phase of the printing roller is adjusted,the cylinder will brake all the units rolling running and keep the original location of the gears.3.The slotting unit.(single screw shaft slotting)⑴.The line creasing device.①.Creasing wheel roller material is steel tube with out gaps.②.The surface of the creasing wheel roller is grinded, polished and hard chromium plating. And after balance corrective. ③.The distance between the up and down line creasing wheel roller is adjusted by hands,while the dial show the adjust date,the adjusting scope is 2-12mm.The up and down line creasing wheel roller adopt the crosshead connect with the drive gears,when adjust the distance between the two rollers,the distance between the two driver gears of the two rollers will not changed.⑵.The slotting knife plate moving device.①.The slotting knife plate roller is after two times grinded.Be polished and hard chromium plating. And after balance corrective. ②.The width of the slot is 7mm.③.The slotting knife is sawtooth, adopt alloy steel material and after heat treatment and grinded, more hardwearing and sharp-edged.④.The cardboard cutting knife is adopted alloy material after heat treatment and grinded, more hardwearing,sharp-edged and high precise.⑤.The slotting knife plate and line creasing wheel are synchronous move left and right,adjust by electrically,control by button and colorful touch screen.⑥.The four slotting knives are synchronous moving for adjust the high of the carton box,adjust by electrically,control by button and colorful touch screen.⑦.The distance between the up and down slotting knife plate roller is adjusted by hands,while the dial show the adjust date,the adjusting scope is 2-12mm.The up and down slottingknife plate roller adopt the crosshead connect with the drive gears,when adjust the distance between the two rollers,the distance between the two driver gears of the two rollers will not changed.⑵.The clockwise and anticlockwise phase adjustment of the slotting unit.①.Adopt satellite gear structure for adjust the clockwise and the anticlockwise phase of the slotting knife plate.②.The clockwise and the anticlockwise phase of the slotting knife plate is adjusted by the PLC and electricity,360° could be adjusted while the machine running or stop running.4.The die-cutting unit.⑴.The rubber cushion roller.①.The rubber cushion roller is steel material,the surface is grinded and hard chromium plating.②.The rubber cushion roller after balance correction.③.Rubber cushion adopt fastening-type excellent rubber.Easy to install and uninstall. Long service life,can be cutted 4million to 6million times.④.Adopting mechanical control the position move left and right of the rubber cushion roller.The movement distance is 40mm. This structure makes the rubber covers equally wear,which can increase the use time.⑤.The automatic Pneumatic control Up-down device of the rubber cushion roller is synchronous with the cardboard feeding system.(when the cardboard is fed,the rubber cushion roller is go down and cut the cardboard,when cardboard feeding is stop,the rubber cushion roller will go up and separated from the die. )⑥.The unique speed compensation device can make the fine rubber cushion roller rolling running with the die,no matter how the diameter of the rubber cushion changed,the surface speed of the rubber cushion is completely controlled by the die.This could make the shape of the carton sheet absolutely equal to the die pattern without people operation.⑦.There is a rubber cushion repair device with the machine,the rubber cushion can be used again after be repaired.⑵.The die roller.①.The die roller is steel material,the surface is grinded and hard chromium plating.After balance correction.⑶. The clockwise and anticlockwise phase adjustment of the die-cutting unit.①.Adopt satellite gear structure for adjust the clockwise and the anticlockwise phase of the die roller.②.The clockwise and the anticlockwise phase of the die roller is adjusted by the PLC and electricity,360° could be adjusted while the machine running or stop running.5.The stacking unit. 1.Stripper arm can be operated in inching or automatic mode. 2.Stripper arm belt can be independently adjusted for degree or tightness. 3.Collection platform elevation be driven by strong chains. 4.Collection platform inclination height can be adjusted with the carton stack height and the elevation motor incorporating electric braking function to keep the platform stable. 5.Stripper carrier acting afterwards by carrying cardboards with automatically stretching collection plate when the cardboards are stacked up to the preset heigh. 6.Stacking heigh is 1600mm.6.The drive gears.⑴.All the drive gears is adopted 20CrMnTi high quality alloy steel,after thermal refining, high frequency hardening and high-precision gear grinding.⑵.Gears hardness is HRC55,long use time,low noise and high produce precision.⑶.The gears adopted automatic and circularly lubricate.7.Mail technic parameter Items/modelRYKM9522RYKM1224RYKM1228Max. feeding size950×2400mm1270×2600mm1270×3000mmMin. feeding size270×600mm380×600mm380×600mmMax. Printing Area920×2200mm1200×2400mm1200×2800mmSkip Feeding1100×2400mm1450×2600mm1450×3000mmMin. Slotting space (mm)280×80×280×80mm(Normal knife)160X160X160X160(Reverse knife)280×80×280×80mm(Normal knife) 160X160X160X160(Reverse knife)280×80×280×80mm(Normal knife) 160X160X160X160(Reverse knife)Max. Slotting depth235mm320mm320mmPrinting plate thickness7.2mm7.2mm7.2mmPaperboard thickness2-11mm2-11mm2-11mmMax. Machine speed (pcs/m)180pcs/min180pcs/min160 pcs/minFeeding precision±1.0mm±1.0mm±1.0mmPrinting precision±0.5mm±0.5mm±0.5mmSlotting precision±1.5mm±1.5mm±1.5mmDie-cutting precision±1.0mm±1.0mm±1.0mmSome of the machine photos: Other model machine photos:Main Models: Spare Parts: Our Workshop: Container Loading:Exhibitions:Company Certificates:

Other supplier products

|

|

MJSF-320FX Single Facer (Square Model) |

Cangzhou ROYAL Packing Machinery Co.,Ltd is one of the leading China mjsf-320fx single facer (square model) manufacturers,Website:, welcome to whol... |

|

|

MJNC-2 NC Cutter |

MJNC-2 NC Cutter,Website: Paperboard NC Cutter |

|

|

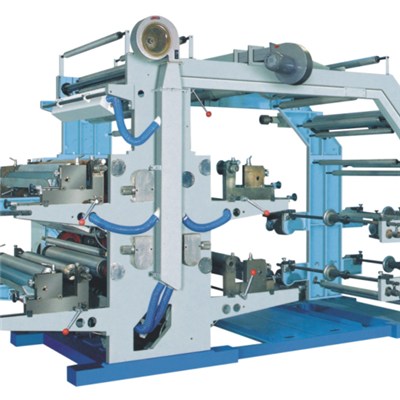

RYTY-Flexography Printing Machine |

Cangzhou ROYAL Packing Machinery Co.,Ltd is one of the leading China ryty-flexography printing machine manufacturers,Website:, welcome to wholesale... |

|

|

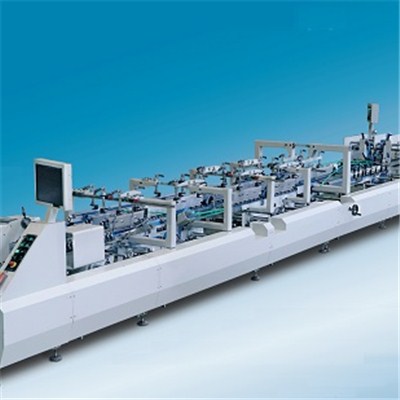

RYJE High Speed 4,6-Corner Box Automatic Folder Gluer |

RYJE High Speed 4,6-Corner Box Automatic Folder Gluer,Folder Gluer Machine |

|

|

MJFM-2 Water-Base Film Laminated Machine |

MJFM-2 Water-Base Film Laminated Machine,Film Laminating Machine |

All supplier products

Same products