Tool Design

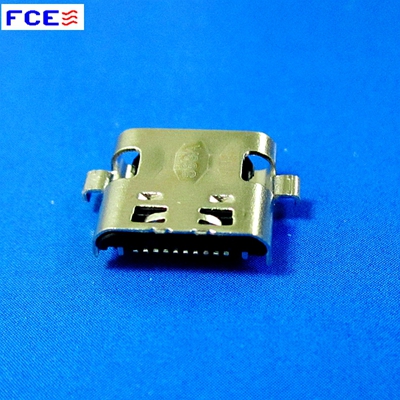

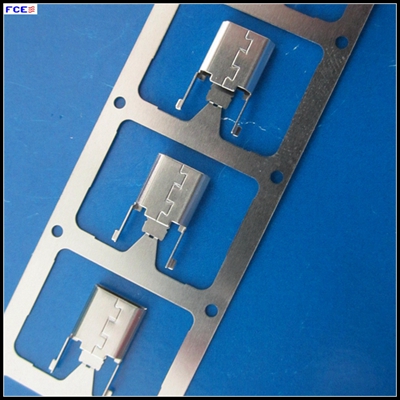

Tool & Die Design & ManufacturingAtFce,Website: preciseleadframe,Fceoffersourcustomersawidevarietyofdiesandstampingincluding:stamping,forming,blending,andprogressiveandtransferstamping.Design Engineering ServicesFceoffers excellent design engineering. Our R&D, consulting, design, prototyping and reverse engineering are hard to beat and we are proud that the geometry of our drawings (CAD, CAM) will carry over to a wide variety of machines. We offer an amazing array of services (CNC machine, wire and sinker EDM, drilling, countersinking, tapping and reaming, just to name a few) and we provide tooling to make your parts.Creative Design SolutionsWe work closely with our clients to create solutions and innovations that work! We have creative design strategies and critical problem solving that will lead to increased revenues for our clients.Tool & die design key technology analysisThe successful development of a set mold is based on proper design,we after many times test mode just know how to achieve good design,but it is too late.Then we need to spend a lot of time and manpower to correct.Key technology of stamping die design &analysis contains mold design,application of CAD technology and application of CAE technology.Mold design contains project planning or material list,which includes die stress balance and adjustment engineering and space station design,and the die structure design,which includes design pressure plate pressure,mold rigidity and strength design,die edge design control insert design.Application of CAD technology includes computerized design date,standardization of parts,module and unit,the parametric design method,application of CAD technology,Two dimensional CAD system(continuous die).Three dimensional CAD system(sheet metal die),Specific CAD design software user guide.Application of CAE technology includes simulation analysis of being spring back、simulation analysis of the forming limit of sheet metal,the text mode of computer technology.Through the application of CAE analysis software at present,we can make the mold design quality better in the design phase to simulate forming process in order to understand the die design of the appropriate degree of surface when design changes.Meanwhile we can reduce the number of test mode and mold development time.

Other supplier products

All supplier products

Same products