Cylinder Liners

Mud Pump LinersGaoton can offer Bi-metal liners as well as ceramic liners for all popular mud pumps to suit any drilling condition, including Bi-metal Liners and Ceramic Liners.Bi-metal LinersOur bi-metal liners combine the strength of a forged steel outer shell with the abrasion and corrosion resistance of a high chrome inner sleeve. These liners feature a centrifugally cast high chrome iron sleeve which is machined and heat treated to a minimum uniform bore hardness of 59-65HRC. Each liner is machined to close tolerances to assure ease of installation and long liner life with the inside diameter of these premium liners honed to a mirror-like finish for smooth even wear during the life of the liner. Our premium liners are made for superior performance under tough corrosive and abrasive conditions.Bi-metal Liners is the main expendable parts of the mud pump,it adapts double metal fix together.The outer sleeve is forged steel with quality carbon steel,the inner sleeve is casted with high carbon and high chromimum use the technology of centrigual casting, after treatment ,the hardness of it can reach to a level of 59-67HRC.The bi-metal liners produced by us strictly control the tolerance ,assure the easy installation, inner sleeve is highly polished whit abrasion&corrosive resistance,can used in various bad working environment with linger service life.Liner Outer Sleeve: 45# forged steel,tensile strength is δb ≥610Mpa ,yield strength is δs≥450Mpa,elongation hardness is E≥17%,hardness is HRC180-200Liner Inner Sleeve :high chromium cast iron(centrifugal forged). Annealing hardness is HRC≤ 40.Quenching hardness is HRC59-67Chemical Composition C 2.8%-3.1% Cr 26%-28% Si 0.6%-0.9% Mn 0.5%-1% Mo 0.5%-0.8% S.P≤0.05%Ceramic Liners:Our ceramic liners combine the strength of a forged steel outer shell with the abrasion and corrosion resistance of a ceramic inner sleeve. We provide Zirconia(ZrO3) Sleeves as well as Alumina(Al2O3.) sleeves., of which Zirconia exhibits better impact strength, higher hardness and be honed to finer surface finishes than alumina. Ceramic cylinder inner sleeve is used zirconia toughening alumina ceramics obtained the national patent, using zirconium oxide the characteristics of high fracture toughness and high hardness of alumina, the combination of these two can improve the fatigue strength of the product, its performance is superior to the traditional alumina ceramics. Its coat uses 45 steel forging with good mechanical properties. After tempering heat treatment, hardness of HB235-265, the tensile strength is not less than 655 mpa.If you have any further requirements, please feel free to contact us

Other supplier products

|

|

Rotary Kelly |

Rotary KellyKelly is the drive part of whole drill string, it transmit the torsional energy from the rotary table to the bit in the bottom of the h... |

|

|

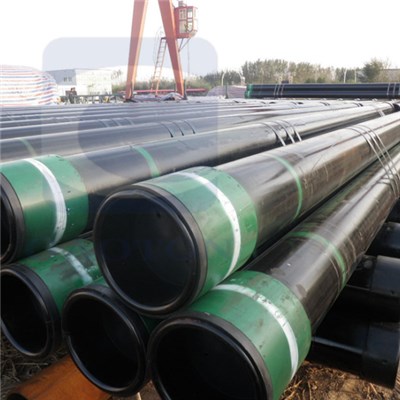

Oil Country Tubular Goods |

Oil Country Tubular Goods is also shorted as OCTG, mainly used for oil and gas well drilling, gas transmission. It include oil drill pipe, casing, ... |

|

|

Float Valve Sub |

Float Valve SubFloat Valve Sub is usually connected on the top of the bit to control down hole liquid. While stopping pump and connecting with sing... |

|

|

Casing Head |

Casing HeadCasing head is used to fixed well drilling wellhead, connecting wellhead casing string, to support the gravity of the technology of casi... |

|

|

Type DD Elevator |

Type DD ElevatorType DD center latch elevator with square shoulder are suitable for handling drill collar, casing and tubing. The load ranges from ... |

All supplier products

Same products