CVD Diamond

Industrial diamond powdershas the characteristics of high thermal stability, high chemical stability, good conductivity, good physical properties (high compressive strength, good heat dissipation, strong corrosion resistance, low thermal expansion rate) and so on. It has high hardness and good wear resistance, and can be widely used for cutting, grinding and drilling. Diamond abrasive powderhas high thermal conductivity and good electrical insulation, can be used as a heat sink for semiconductor devices, has excellent light transmission and corrosion resistance, and is widely used in the electronics industry.

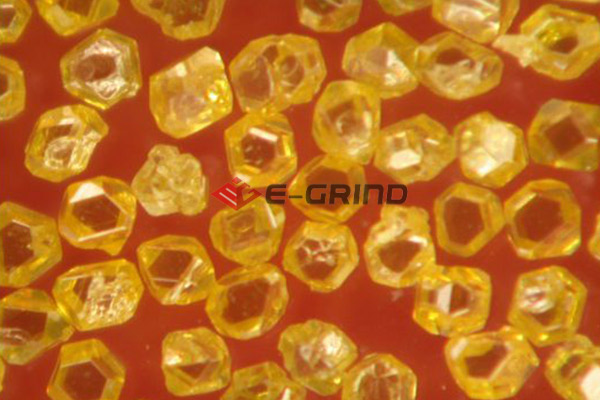

CVD (Chemical Vapor Deposition) diamond. The mixture of carbon-containing gas and oxygen is excited and decomposed at a high temperature and a pressure lower than the standard atmospheric pressure to form an active diamond carbon atom, and the deposit is alternately grown on the substrate to form a polycrystalline diamond.

The high hardness and high wear resistance of diamond make diamond films an excellent tool material. One of the important properties of chemical vapor deposition diamondis its extremely high thermal conductivity. At room temperature, the thermal conductivity of diamond is five times that of copper. At the same time, it is an excellent insulating material. Therefore, diamond films can be used to make high-power optoelectronic components of the heat sink material. Application of vapor deposition diamondoptical properties. Diamonds have very high spectral passivities over a long wavelength range from ultraviolet to far infrared. In addition to the outstanding mechanical and thermal properties of Diamond, Diamond Film is an excellent cvd diamond windowmaterial that can be used in harsh environments.

In other applications, acoustic waves produce high-quality diamond thin-film acoustic devices at extremely high propagation speeds in diamonds, using chemical stability of diamonds to make various types of biosensor devices.

E-Grind supplies various shaped CVD diamond. CVD has very similar features as diamond.

Our Polycrystalline CVD diamond is manufactured by DC Arc Plasma Chemical Vapor Deposition (CVD) method. They can be made into dressing tool blanks, wire drawing die blanks, laser windows, domes and thermal mounts etc in mechanical, thermal management, optical windows industries. E-Grind CVD provides long using life and high working efficiency.

CVD diamond can be used for Dressing application in grinding process. It is suitable for the single point, multipoint, blade, rotary, roller etc It has superior thermal characteristics and very wearing resistant.

CVD diamond can be used in mechanical working for non-ferrous materials such as ceramics, high silicon-filled aluminum, abrasive composites, graphite etc. With high thermal conductivity, low friction index, high anti-wearing features, it provides premium performance as cutting tool application.

CVD diamond has unique characteristics of thermal conductivity, which is five times higher than that of copper. We supply thermal management grade of CVD, which with thermal conductivity between 1000-2000 W/mK,

Application

Laser diodes, high-power integrated circuits, a heat spreader for satellite and GaN on Diamond.

Specifications

Density: 3.5g/cm3

Young's modulus: 1000-1100Gpa

Growth side surface finish: <100 nm Ra

Nucleation side surface finish: <30 nm Ra

With the advantages of thermal conductivity, broad-band optical transparency and hardness, CVD diamond can be used for microwave windows, laser windows... In these fields, our CVD diamond provides high transparency, low scattering in infrared, high thermal conductivity.

Advantages

Application

1) For Cutting tools

Monocrystal CVD diamond is widely used for cutting tool industry, including Turning Drilling Boring, Milling cutting tools.

2) The workpieces for cutting are as below:

The CVD Mono Diamond is suitable for being used as Optical Window, Laser Crystal of High Power Laser Device, Camera Lens of Large Power UV/IR Optical Instrument and sensor, Detector needs to be worked in extreme environment.

CVD Mono crystal diamond can be applied to High-power laser, microelectronics Heat Sink component, etc.

CVD Mono crystal diamond can be made into a variety of high-end luxury jewelry diamond.

Send product request

Other supplier products

| CBN Powder | The cubic boron nitride has a molecular formula of BN. Its atomic structure is similar to the structure of carbon atoms in diamond. Therefore, it h... | |

| Diamond Wire Drawing Die Blanks | E-Grind is a professional PCD wire drawing dies supplier and manufacturer, we provide two series of Diamond Wire Drawing DieBlanks: CDB Series and ... | |

| E-Grind Superabrasives Product | E grindis a professional superabrasive ltd, we provide superabrasive, pcd diamond cutting tools, pcd diamond inserts, pcd diamond tools, diamond po... | |

| Saw Grit Diamond | E-Grind's Saw Grit series are with cube-octahedron particles, for stone and construction engineering industries such as Granite, Marble, Concrete, ... | |

| CBN Powder | The cubic boron nitride has a molecular formula of BN. Its atomic structure is similar to the structure of carbon atoms in diamond. Therefore, it h... |

Same products

| 8×8mm Asscher Cut Blue Diamond Color Moissanite 10K Rose Gold Engagement Ring | Seller: Guangxi Wuzhou Starsgem Co., Ltd | 8×8mm Asscher Cut Blue Diamond Color Moissanite10K Rose Gold Engagement Ring Product Descr... | |

| Starsgem 1ct D VVS2 Oval Brilliant Cut IGI HPHT Lab diamond | Seller: Guangxi Wuzhou Starsgem Co., Ltd | Starsgem 1ct D VVS2 Oval Brilliant Cut IGI HPHT Lab diamond Product Description Material:HPHT L... | |

| Wafer Back Grinding Wheel | Seller: Henan E-Grind Abrasives Co., Ltd. | E-Grind Back-Grinding wheels have developed the technology to combine diamond and bond to meet yo... | |

| Vitrified Bond Grinding Wheels | Seller: Henan E-Grind Abrasives Co., Ltd. | The diamond and CBN are held in place by ceramic components that are fused to form the abrasive p... | |

| Metal Bond Diamond Grinding Wheels | Seller: Henan E-Grind Abrasives Co., Ltd. | The metal bond diamond wheelis made from the sintering of alloy powders and other fillers with ei... |