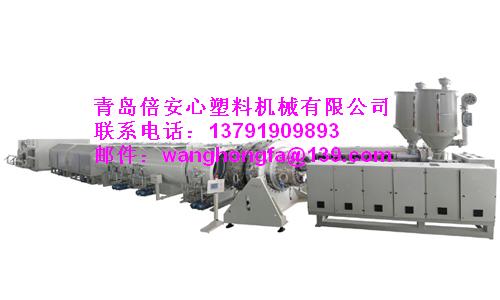

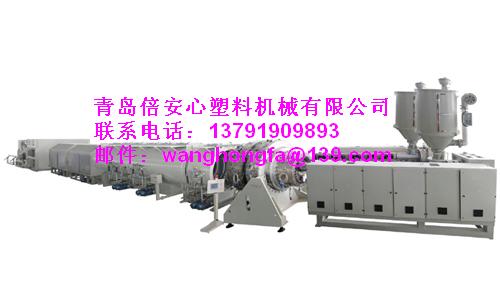

plastic extruding machine

1) Main machine uses PVC twin screw, and notch feeder with powerful water

cover cooler, which has greatly improved transmitting capability and ensured

extruding.

2) Adopting double pipe extrusion method, it can greatly increase productivity.

3) Adopting high efficiency double-cavity vacuum calibrating technology and spray-paint

cooler gullet, which improve the finished product passing rate, and meet

the requirements of high speed manufacturing. Vacuum calibrating platform and cooler

gullet are all made of stainless steel

4) Adopting multi-caterpillar haul-off, through the central motor to run all the caterpillar

to reach same height, and ensure roundness of pipes

5) Adopting fully automatic control system with high precision, reliable operation,

easy and convenient handling

6) Suitable pipe diameter: 20 - 630mm

Other supplier products

|

|

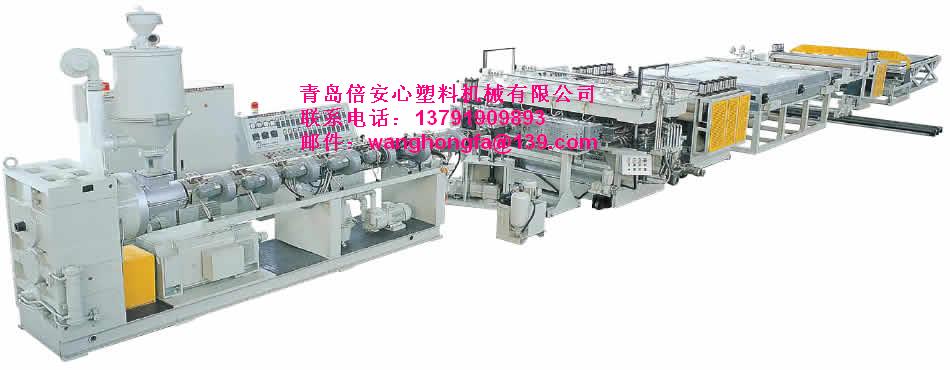

PET PP PE PS ABS SHEET PLATE PRODUCTION LIEN |

specialized in manufacturing pp, pe, ps, abs single layer and multi layer co-extrusion plate and board production line. Product thickness varies fr... |

|

|

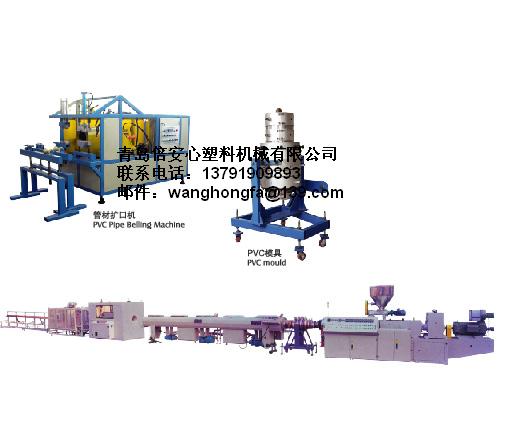

PVC WPC profile production line |

wood-plastic extrusion line uses a specially designed screw barrel, mold and extruding machine production of wood-plastic products processing produ... |

|

|

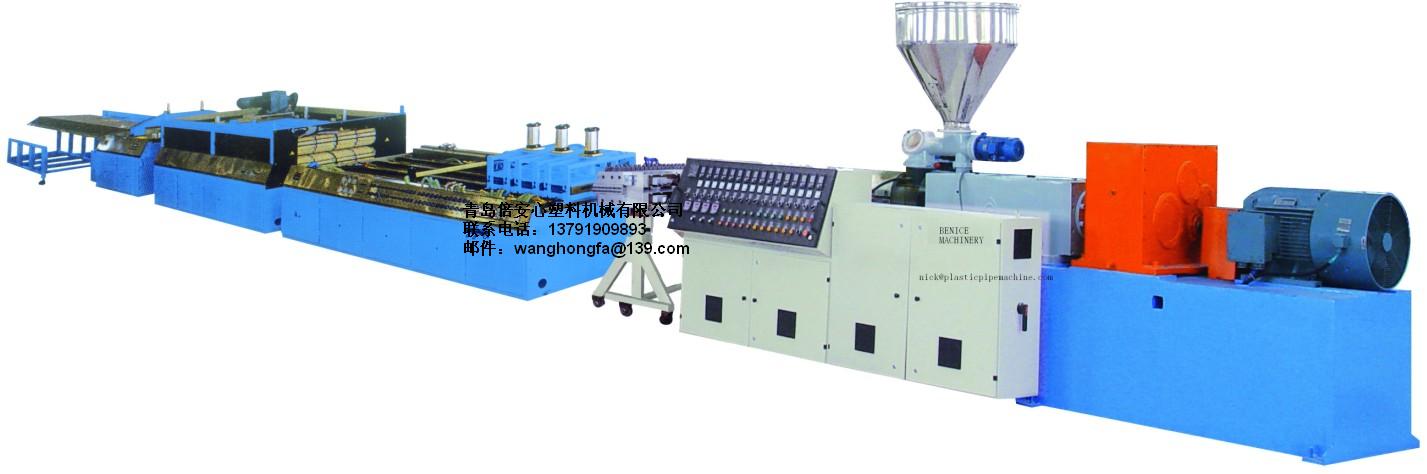

Widely used plastic hollow board production line |

Brief introduce :

The special equipment directly extruder molding hollow grid ,with the product bright surface ,clean artistical and compress... |

|

|

PS sheet production line |

PS Sheet Making Machine

PS sheet is a kind of new-type packing material with the features of shockproofing, sound insulation, heat preservation, da... |

|

|

PVC WPC door board production line |

the unit uses a specially designed sjsz80 conical twin-screw extruder, using imported inverter, use imported rck temperature controller, with a wid... |

All supplier products

Same products