Continuous Filament Winding Machine

CFW Machines for Manufacturing Quality FRP Pipes

Continuous filament winding machine, abbreviated to CFW machine, is designed to manufacture FRP or GRP pipes with similar work principle toDFW machines. However, CFW machine has different areas where filament winding is laying out - continuous winded steel bands with smooth surface.

CFW machines can be used to produce various types of pipes such as polyester pipe, polyester sand inclusion pipe and epoxy or PVC composite pipe. These pipes manufactured by our CFW have excellent axial strength and widely used for storing drinking water, building water sewage projects, drainage engineering and various anti-pollution projects in chemical industries.

Continuous filament winding machine

Feature:

- Ideal for produce pipes in a wide range of diameters from 0.25m to 4m.

- High productivity - the production speed of CFW machine is over 60m per hour.

- Microcomputer control system allows stable performance and easy operation - just inputting small amount of parameters that effectively reduces human errors.

- Superb feeding system ensures the raw materials are distributed evenly for higher pipe quality and lower material waste.

- Sand premix system reduces resin content for saving cost up to 25%.

- Improved system allows for about 40% time reduction in full diameter range.

Composition:

- Horizontal cantilever mandrel system - driving device, aluminum beams, roller bearings.

- Band circulation system - steel band pusher, band exit head, placement head and circulating head.

- Pipe raw material mixing & storage system.

- Feeding system.

- Curing system for infrared heating and pipe solidifying.

- Winding system - mylar winder, surface veil winder and external layer winder.

- Pipe holding, anti-distortion, cutting and unloading system, etc.

- Liner chopper device.

- Chopped roving shelf and hoop roving shelf, etc.

Operation process of CFW machine

Process:

Step 1:Mounting roller bearing

Slip the outward-facing roller bearings on the principal axis.

Step 2:Mounting aluminum beams

Fix aluminum beams to the grooves of roller bearings.

Step 3:Steel band winding process

Wind steel band around the forward moving mandrel with the help of a placement head on the mandrel’s supported end. Normally, the steel band is about 2” in width, and the mandrel moves forward about one band width when it rotates a circle. Then the steel band is winded to form a smooth mandrel for raw material feeding. At the end of the mandrel, the steel band is guided by exit head to turn back to the mandrel’s core. And then the placement head re-direct the band on the mandrel again for recycling usage.

Step 4:Feeding process

After the circle system of steel band is finished, then wind a layer of lining film around the steel band and make processed pipe raw materials winded around steel band and gone forward with the mandrel.

Step 5:Solidifying & extraction

Cure the winded pipe until it is solidified. Then extract the pipe from mandrel system.

Step 6:Cutting & unloading

Cut the pipes into custom length and transport them to the construction site.

Specification:

| Model | Pipe diameter |

| CFW1200 | 250mm to 1200mm |

| CFW2600 | 300mm to 2600mm |

| CFW3000 | 300mm to 3000mm |

| CFW4000 | 400mm to 4000mm |

Send product request

Other supplier products

| FRP Grating & Stairs | Fangchen specializes in designing, manufacturing and selling FRP grating and FRP stairs in an extensive range of styles and sizes that are needed i... | |

| Extraction Machine | Extraction Machine Provides Reliable Demoulding Extraction machine, also known as demoulding machine, is specially made to strip finished FRP, RPMP... | |

| Discontinuous Filament Winding Machine | DFW Machines - Precise, Versatile & Convenient Discontinuous filament winding machine, also known as DFW machine, is an auto device for winding... | |

| Trimming Machine | Mandrel & Pipe Trimming Machines in High Precision We all know that mandrels are musts and represent the industrial standards for manufacturing... | |

| FRP & RPM Pipe Production Line | FRP & RPMP production line is the best solution for manufacturing reinforced plastic mortar pipe (RPMP) and other fiberglass reinforced plastic... |

Same products

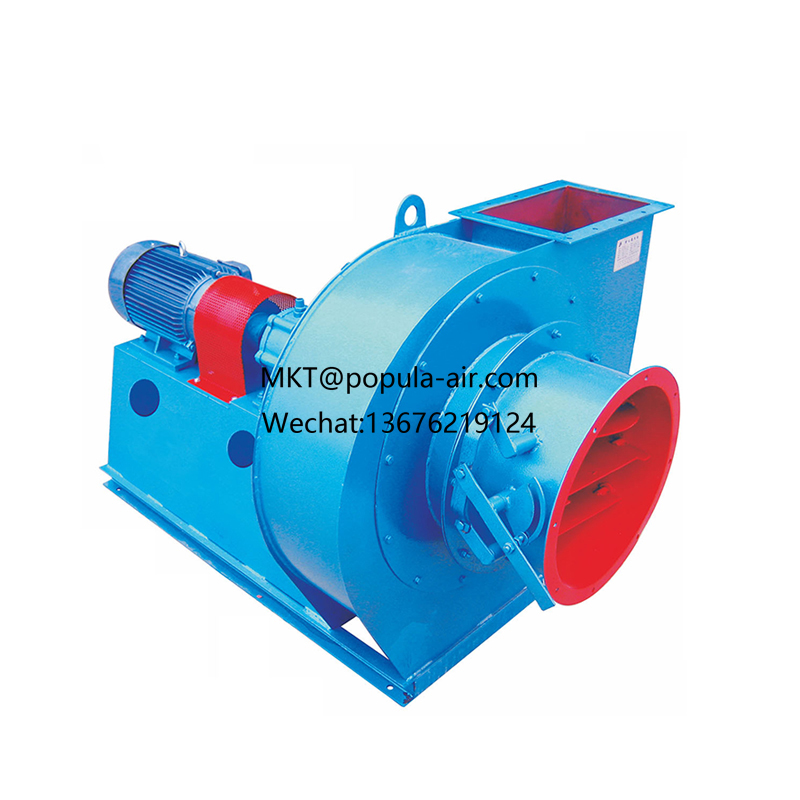

| Y9-35-13.5D-75KW with volume 2834-2893 pressure POPULA boiler centrifugal induced draft fan | Seller: Popula Group Company Limited | Puduct Name: Y9-35-13.5D-75KW with volume 2834-2893 pressure POPULA boiler centrifugal induce... | |

| Ultrasonic Computerized Tape Cutting Machine (Right Angle) JM-2100 | Seller: Zhejiang Huaqi Information Technology Co., LTD | Fully automatic cutting, easy operation. Wide application range, high cutting quality, smooth cut... | |

| 24 Cavity Cap Compression Machine | Seller: Zhejiang Huaqi Information Technology Co., LTD | The 24 Cavity Cap Compression Machine is an advanced piece of equipment designed to meet the dema... | |

| 24 Cavity Cap Compression Machine | Seller: Zhejiang Huaqi Information Technology Co., LTD | The 24 Cavity Cap Compression Machine is an advanced piece of equipment designed to meet the dema... | |

| SWT-UME Hot Air Welder Pvc Tarpaulin | Seller: HEBEI MINGMAI TECHNOLOGY CO.,LTD | SWT-UME Banner Hot Air WelderVoltage: 220V/110VPower: 3000W/2200WFrequency: 50/60HzTemperature: 2... |