Conveyor belt repair materials

Conveyor belt repair materials

When mentioned about conveyor belt, many of us will think about the movement of materials, ore, coal and so on, which plays a great role in our daily life, improve work efficiency, while, along with the overload transportation and equipment installation problem, conveyor belt will be damaged from different levels, even endanger the safety of production.

Traditional conveyor belt repair is obsolete, such as belt buckles, wire ties and so on, “ as long as it doesn’t affect the normal operation, bundle it casually”, this is the original opinion to conveyor belt, however, which accompanies with conveyor belt surface damaged, longitudinal tear will be even worse, materials will be side leak from conveyor belt, which may even breaks and endanger the production safety, so you can image the availability of conveyor belt.

For sample, Ramimtech does conveyor belt repair in Sichuan province.

For our client’s request, we did conveyor belt repairing for a large scale state owned aluminium ore enterprise, in fact, our stuff have make full consideration for all problems, such as cold vulcanization repair, hot vulcanization repair and so on, but when we arrive at the site, we have faced all the problems that can reach, it is really a hard work for our stuff, conveyor belt was bundled tightly by wires, some damaged parts were screwed on, however, what can you imagine, here you can see.

There is no other methods, we have to combine cold vulcanization and hot vulcanization together, after 10 days’ fighting, we finished this construction work, however, the process is very awful, but the reward is high, more than 10 thousand RMB.

From this construction work, it proves that we should periodically maintain our conveyor belt, even small repair, we should find a good way, not use the traditional methods, or it will damage the conveyor belt deeply.

Since we have mentioned the traditional repair, also we will talk about the new repair technology- Rammimtech conveyor belt cold vulcanization repair.

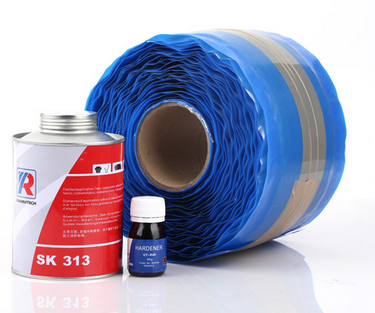

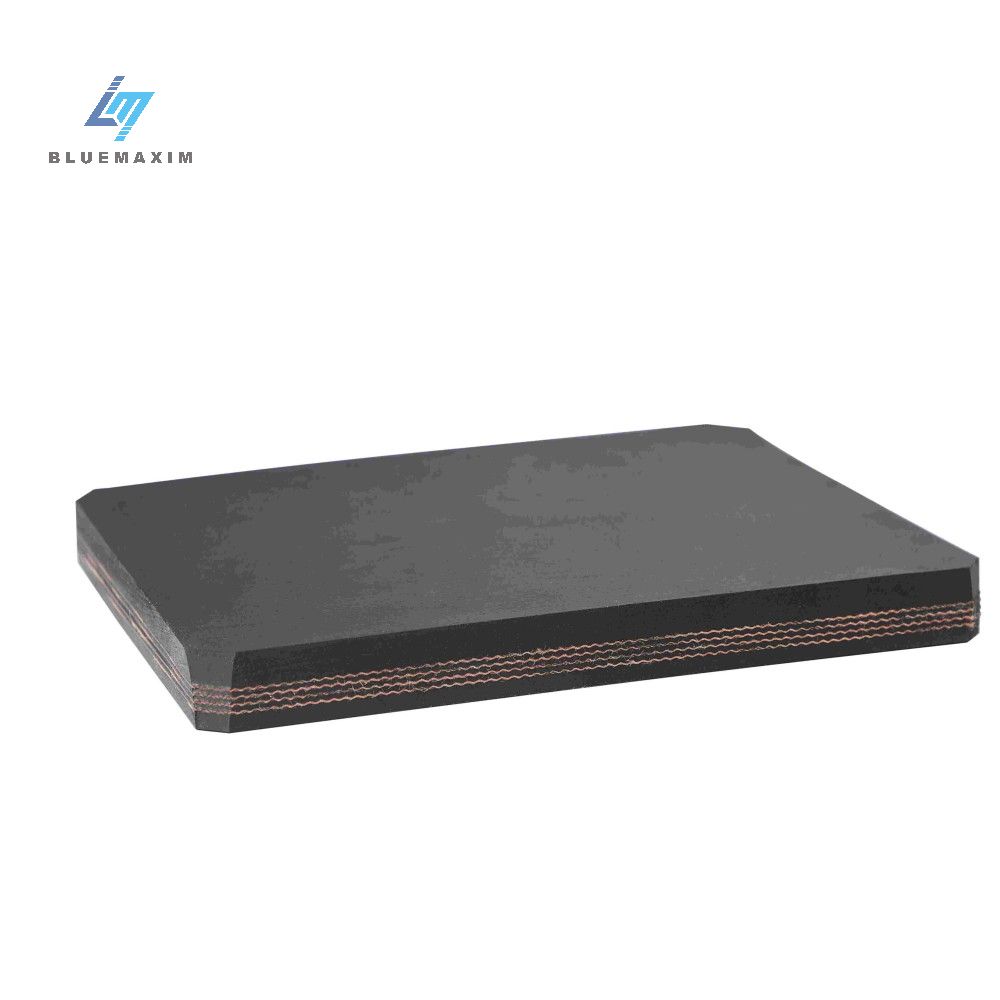

Above photo is conveyor belt part repair material, repair patches and cold vulcanization glue Sk313, repair patches with diamond design, this special industrial design that has the characteristics of “ middle high, surroundings low”, thus can avoid secondly damage to repair parts from sweeper, whose back side is designed by BL coat, will react with cold vulcanization glue SK313, thus it will tightly combine with the conveyor belt.

Above is the application of conveyor belt repair, pls notice that repair patch has limitation, just suitable for partly damages of conveyor belt, we have 3 kinds of repair patches, 160mm*130mm, 260mm*200mm and 360mm*270mm, they have two kinds of thickness, separately 2.4mm and 3.8mm, when choose repair patches, pls consider well.

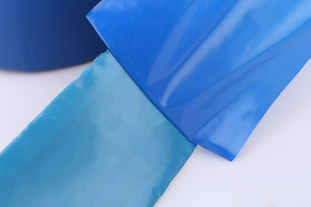

Above photo is long distance repair materials for conveyor belt, repair strip and cold vulcanization glue Sk313.

Obviously, the differences between repair strip and repair patch is that repair strip is for long distance scratching and tear, at present it has 4 dimensions, 100mm, 150mm, 220mm, 300mm and 400mm, each length is 10000mm, just the thickness is different, also repair strip is “middle high, surroundings low”, whose back side is also applied with BL coat, can vulcanize with Sk313 glue, thus increase the bonding strength.

So much of above, we will talk about sk313 glue, which is a high bonding strength glue that far more exceed Germany Industrial DIN standard, mainly for jointing rubber to rubber, rubber to metal, rubber to fabric, fabric to fabric, used for conveyor belt repair, conveyor belt cold vulcanization joints and pulley lagging, suitable for any extreme surroundings.

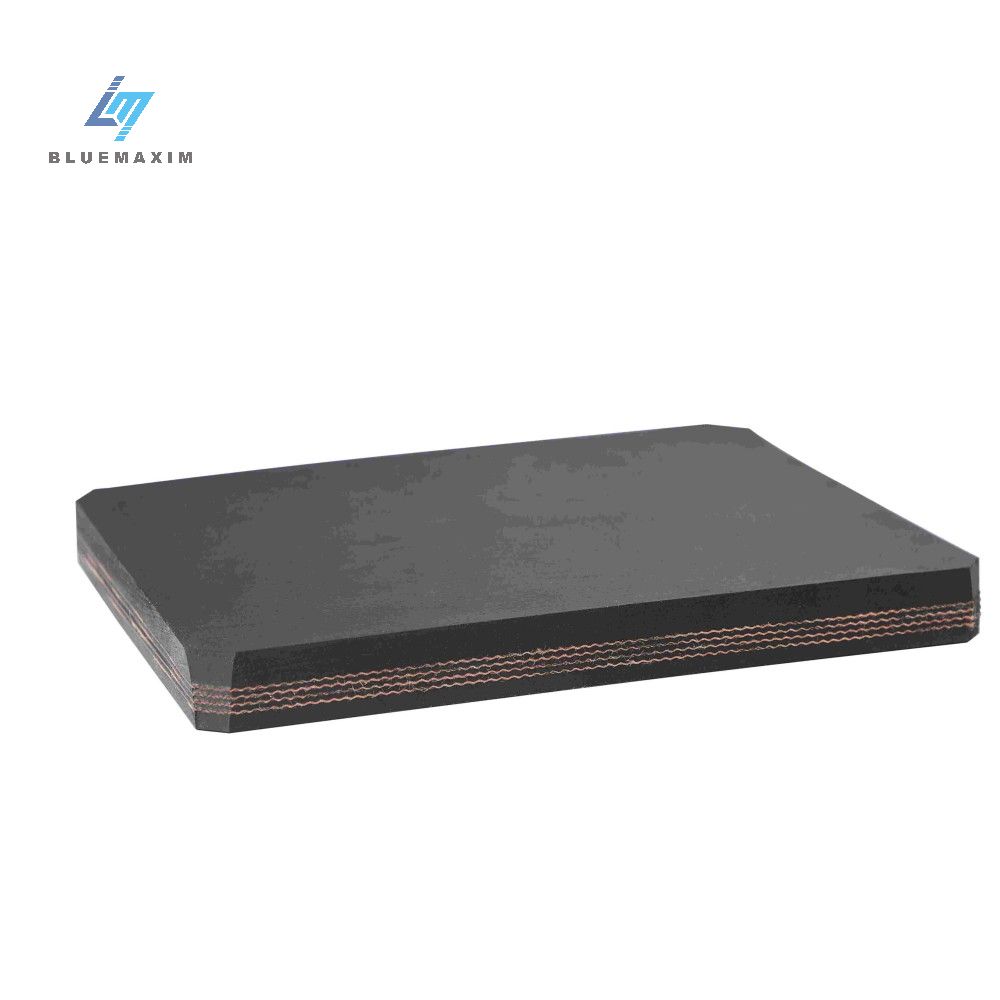

Above is Ramimtech conveyor belt cold vulcanization repair system, thus can realize conveyor belt cold vulcanization repair, not only save time, also after repair can use it immediately, will not cause secondly burden to conveyor belt, thus can increase productivity and service life, real benefits to enterprises.

Send product request

Other supplier products

| what kind of glue we should use when bond metal drum with rubber? | what kind of glue we should use when bond metal drum with rubber? when we do pulley lagging , we need bond metal surface of pulley with rubber shee... | |

| Abrasion Resistant Rubber Sheet | Abrasion Resistant Rubber Sheet Ramimtech abrasion resistant rubber sheet is the most excellent rubber sheet in the world, which suitable for high ... | |

| Ramimtech repair strip | Ramimtechrepair strip Ramimtech repair strip is a special material for conveyor belt repair, which is suitable for conveyor belt surface damage, sc... | |

| Rrepair strip with CN bonding layer need to be roughened when is it be bonded to conveyor belt ? | Rrepair strip with CN bonding layer need to be roughened when is it be bonded to conveyor belt ? If we don't roughten repair strip , could it be bo... | |

| How to use repair strip to repair conveyor belt? | How to use repair strip to repair conveyor belt?Repair strip is used for conveyor belt cold repair, but many customer do not know how to do after t... |

Same products

| anti radiation material | Seller: Xiongxian texcraf Technology Co., LTD | anti radiation material focuses on functional yarns and fabrics,and has a silver plating wor... | |

| Steel Cord Rubber Conveyor Belt | Seller: ZHEJIANG LONGSHENGHUA RUBBER CO.,LTD | are heavy-duty transportation solutions widely utilized across various industries, includin... | |

| Steel Reinforced Conveyor Belt | Seller: ZHEJIANG LONGSHENGHUA RUBBER CO.,LTD | **Product Description for Steel Reinforced Conveyor Belt** **Title: Heavy-Duty – Unma... | |

| Coal Mine Steel Core Conveyor Belt | Seller: ZHEJIANG LONGSHENGHUA RUBBER CO.,LTD | The is an essential component in the mining and materials handling industries, specifically... | |

| application of Conveyor belts in Construction | Seller: ZHEJIANG LONGSHENGHUA RUBBER CO.,LTD | Bluemaxim's conveyor belts are vital in the construction industry, facilitating the efficient... |