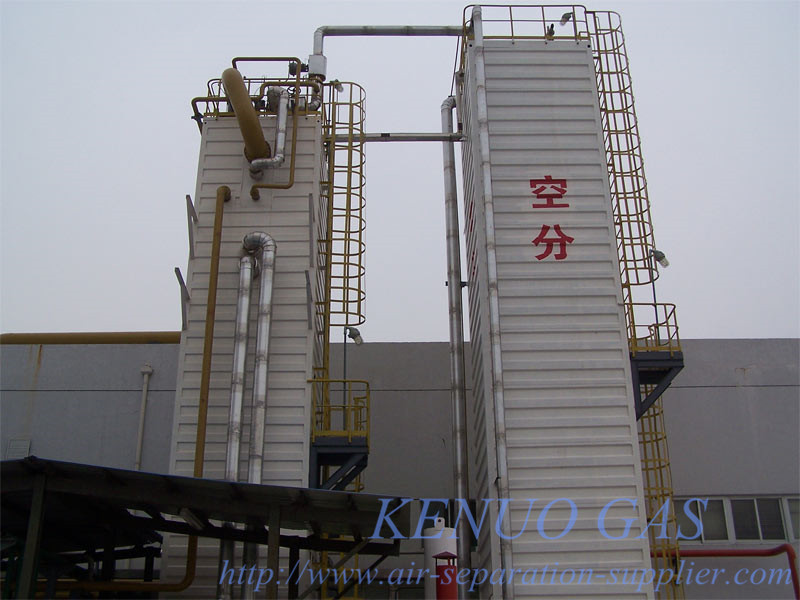

Air Separation Plant

Air which was sucked in from air intake tower enters the suction air filter and after being removed of dust and other mechanical contaminants in it, it is compressed to the pressure of 0.55MPa by centrifugal air compressor. Air from the air compressor is cooled to 10C in the direct contact after cooler and refrigeration unit after the water being separated its condensed water, taken into the molecular sieve adsorber for removing H2O, C2H2 and CO2. There are two molecular sieve adsorbers which operate on a staggered cycle, i.e. one vessel is adsorbing the contained impurities while the other is being reactivated by waste nitrogen from the rectifying column.

Then the cleaned air is divided into two streams, one of them is taken into the rectifying column and cooled by the returned waste nitrogen, oxygen and nitrogen through the main heat exchanger. The steam-liquid air mixture is taken into the lower column for rectifying, and herein the pure nitrogen of 99.99% from the top of the column enters into the evaporator-condenser and condensed by liquid oxygen from the upper column. A part of the liquid nitrogen is fed to the lower column as reflux. The other part is divided into two streams, one of them after subcooling enters into the top of the upper column after throttled, the other enters crude argon condenser of crude argon column, after vaporized, it enters in upper column.

Another cleaned stream is compressed in booster end of the booster expansion turbine, and then enters the main heat exchanger. Two streams of air from the middle and cold end of the main heat exchanger joint together and enter into the turbine expansion to generate most refrigeration for need of the plant's operation. After the expanded air is removed of overheat through the thermosyphon heat exchanger, it enters to the middle of the upper column for rectifying.

A stream of 8% Ar is drawn from middle-lower section of upper column and enters Crude Argon Column I to be rectified. Gas is drawn from top of Crude Argon Column I and enters Crude Argon Column II, then enters condenser as its reflux. The liquid at the bottom of Crude Argon Column II is pumped into top of the Crude Argon Column I as reflux, the crude argon is drawn from Crude Argon Column I and enters heat exchanger then enters pure argon column, pure liquid argon of 99.99% Ar is drawn from bottom of pure argon column and enters Lar storage & gasification system.

The product oxygen with the purity of 99.8% O2 gained at the bottom of the upper column is warmed up through the heat exchanger and then delivered to the compressed oxygen system.

The LOX of 99.8% O2 is drawn from oxygen side of the evaporator-condenser, some of them enters storage tank as product. The product nitrogen of 99.99%N2 from recycle N2 compression system is supplied to the user for use.

The waste nitrogen from the top of the upper column is warmed up, one part goes to the regeneration molecular sieve adsorber, another goes to waste nitrogen tower to cool the water.

Other supplier products

|

|

Air Separation Plant |

Air which was sucked in from air intake tower enters the suction air filter and after being removed of dust and other mechanical contaminants in it... |

|

|

Energy-Saving Oxygenerator |

Technology IntroductionThe ASP generates oxygen and nitrogen by cryogenics and is comprised of high-efficiency centrifugal compressor, molecular si... |

|

|

Molecular Sieve 13X |

Product Description: Kenuo’s molecular sieve 13X used in cryogenic air separation process has the advantages of excellent adsorption capacity... |

|

|

Movable Motor Drive Screw Air Compressor |

Increasing gas pressure according to individual requirement

Working process: Increasing gas pressure in the cylinder by piston motion |

|

|

Cryogenic Air Separation Nitrogen Generator |

Air which was sucked in from air intake tower enters the suction air filter and after being removed of dust and other mechanical contaminants in it... |

All supplier products

Same products