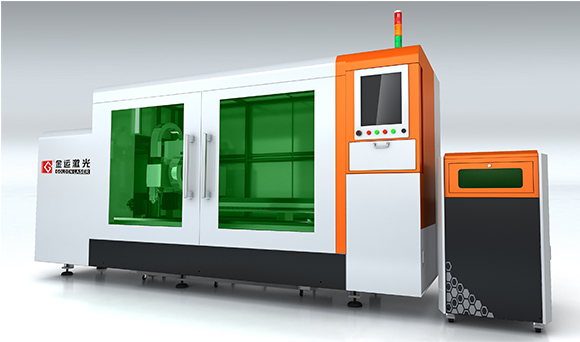

Overview of Heavy Duty Tube Laser Cutting Machine

Large tube laser cuttinguses a focused high-power-density laser beam to irradiate the workpiece, so that the irradiated material quickly melts, vaporizes, ablates, or reaches the ignition point while blowing away the molten material. And with the help of a high-speed airflow coaxial to the beam, thus realizing the cutting of the workpiece. Laser cutting is one of the thermal cutting methods.

We have launched the heavy-duty tube large cutting machine, a large cutting machine, for processing super-long and super-heavy pipes. From automatic feeding to stable clamping, and finally, to automatically receive the finished workpiece, the whole process can be fully automated. Save time and labor for you.

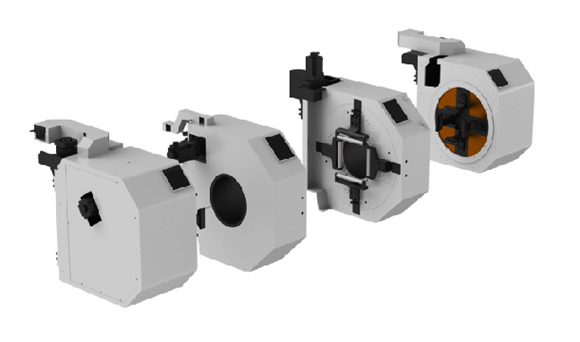

Professional Heavy Chucks

Compared with the general laser pipe cutting machine, the load-bearing weight of the chuck of a large laser cutter is increased to 500kg. The maximum load-bearing capacity of a single tube can reach 1.8 tons. The most extended length supports automatic loading and cutting of 12 meters of pipes.

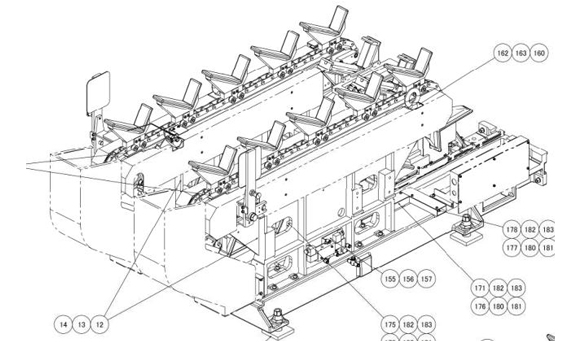

Friendly Operation

The equipped chain-type automatic loading and unloading system can support up to 12 meters of heavy-duty pipe loading and unloading. The number of single preparations can reach 6 to ensure the continuity of the processing process and reduce equipment downtime. Only one person can efficiently complete the entire process.

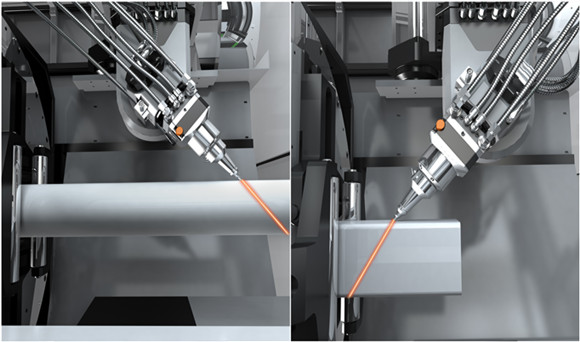

Supports Multiple Types Of Pipes

Large cutting machine fully supports the cutting of round pipes, square pipes, rectangular pipes, elliptical pipes, channel steel, angle iron, I-beams, slats, profiles, special-shaped pipes, etc., and supports bevel processing.

CE Standard

The large cutting machine strictly adheres to the CE standard. The overall safety protection reaches the highest level without worrying about safety.

Application Of Heavy Duty Tube Laser Cutting Machine1

Construction machinery industry:

Many major load-bearing structures in construction machinery use ultra-long and ultra-thick channel steel, I-beams and other pipes. The traditional plasma cutting and flame cutting methods have low processing efficiency and quality. But the china cnc fiber laser cutting machinecan completely solve the problem of heavy pipe processing. In the future, cnc profile cutting will gradually replace these methods. The material texture and style are maximized, and the building's proportions, texture, and space are rigorously expressed. With the delicate mind of laser process, all the structural elements are fully expressed in the sectional plane.

Technical Data of Heavy Duty China Laser Tube Cutting Machine

|

Model name |

P35120 |

|

Workpiece length |

0-12000mm |

|

Tube diameter range |

20-350mm |

|

Type of tube |

Round tube, square tube, rectangular tube, oval tube, channel steel, I-beam, etc. |

|

Single Tube Loading Weight |

|

|

Laser source |

IPG/nLIGHT/Raycus |

|

Laser power |

1500W-6000W |

|

Positioning accuracy |

±0.03mm |

|

Rotational speed |

70r/min |

|

Support bevel cutting |

Yes |

|

Automatic deslag function |

Option |

|

Weld recognition |

Option |

|

Auto feeder |

Standard chain loading and unloading system |

|

Loading size |

6* 12000mm |

|

Laser Cutting Metals And Laser Powers |

||||||

|

Material |

1500W |

2000W |

2500W |

3000W |

4000W |

6000W |

|

Carbon steel |

10 |

12 |

14 |

16 |

20 |

25 |

|

Stainless steel |

6 |

8 |

10 |

10 |

12 |

16 |

|

Galvanized steel |

5 |

6 |

8 |

8 |

10 |

12 |

|

Aluminum |

4 |

5 |

6 |

6 |

10 |

16 |

|

Brass |

3 |

4 |

5 |

5 |

8 |

10 |

|

Copper |

2 |

2 |

3 |

3 |

4 |

6 |

Highlights of Heavy Duty Tube Laser Cutting Machine

Chain Drive Loading and Unloading System

The loading and unloading adopt a chain drive model without manual intervention. Chain drive, choose the chain type and length and tensioning method according to the primary factors such as load, speed, and working environment. The large laser cutter can ensure an accurate transmission ratio, transferring more power and acting on the shaft with less force and high transmission efficiency.

Intelligent Heavy-duty Chuck With Large Clamping Range

Large laser cutter adopts 3 heavy-duty pneumatic chucks with a maximum load of 500kg and a 20-350 mm clamping range. The clamping pressure of the pneumatic chuck supports digital visual adjustment, which is precise and easy to control.

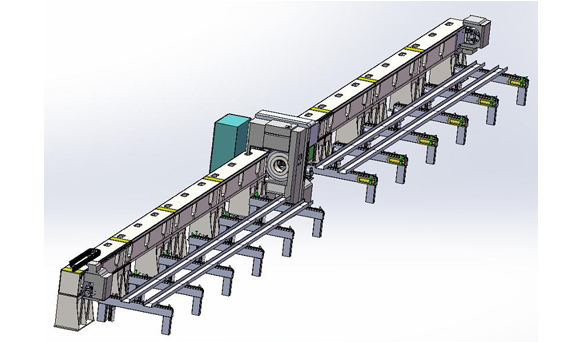

Servo Reducing Wheel Support System

Both the loading end and the unloading end are equipped with servo reduction wheel brackets to increase the load-bearing capacity. When cutting different types of pipes, input the pipe diameter data through the cnc laser pipe cutting system to automatically adjust the wheel support angle. Servo motor control, positioning is more accurate.

No manual adjustment is required, and the operation is more straightforward and safer.

Modular Mechanical Structure Of Side Rail

The large laser cutter adopts the side rail design and chuck suspension type, accommodating larger pipes. The large cutting machine structure adopts the modular design, realizing segmental splicing installation and convenient installation and disassembly. Even if the length of the whole machine exceeds 24 meters, there are no restrictions on transportation.

Send product request

Other supplier products

| 3D 5-axis Laser Tube Cutting Machine Manufacturer | Total 160° flexibility, broader tube processing range and more opportunities to be exploited. Get a quote General Information Overview of 3D 5... | |

| Brass Tube - Laser Cutting Machine Be Applied | Brass is an alloy of copper and zinc. Brass has long been a popular material for decoration for its bright gold-like appearance, e.g. for drawer pu... | |

| Types Of Fiber Laser Tube Cutting Machine For Sale | Golden Laser Smart Laser Tube Cutting Machine Golden Laser Smart Laser Tube Cutting Machine, the leader of the new generation laser tube. Tube las... | |

| 3D 5-axis Laser Tube Cutting Machine P2060A-3D / P3080A-3D | Total 160° flexibility, broader tube processing range and more opportunities to be exploited. Overview of 3d laser cutting machine for sale G... | |

| Heavy Duty Tube Laser Cutting Machine Manufacturer | Automatic 3D laser cutting solution specifically designed for long, heavy tube and profile work. General Information Overview of Heavy Duty Tube L... |

Same products

| SLA 3D UV Laser Printer Machine with Resin China | Seller: Beijing JCZ Technology Co., Ltd | The SLA 3D UV Laser Printer Machineis an advanced and highly precise solution for high-quality 3D... | |

| High-Precision CW Laser Cleaning Machine for Rust & Coating Removal | Seller: Beijing JCZ Technology Co., Ltd | The High-Precision CW Laser Cleaning Machineis engineered for industrial rust removal, coating st... | |

| Tabletop Laser Marking and Engraving Machine for Precision Marking | Seller: Beijing JCZ Technology Co., Ltd | The Table Laser Marking Machineis a high-precision engraving tool designed to meet the demanding ... | |

| ZEUS | Large Size Intelligent-Continuous Laser Processing Software | Seller: Beijing JCZ Technology Co., Ltd | System Advantages High PrecisionCombining multiple correction technologies including autofocus, ... | |

| Single Workstations Cigarette Tipping Paper Laser Perforating Machine | Seller: Wuhan Guan You Technology Co., Ltd. |