free flow drag conveyor chain with powder /granular

free flow drag conveyor chain

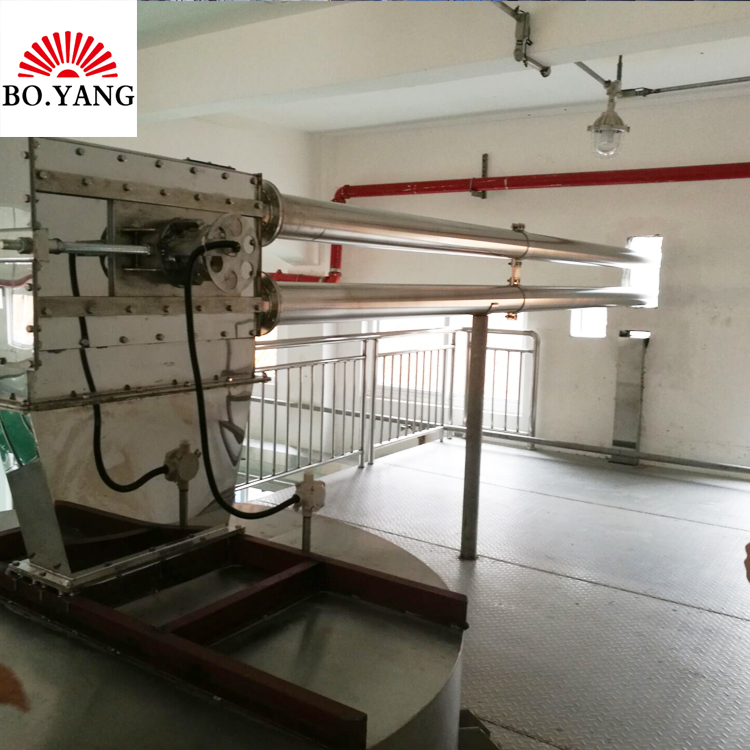

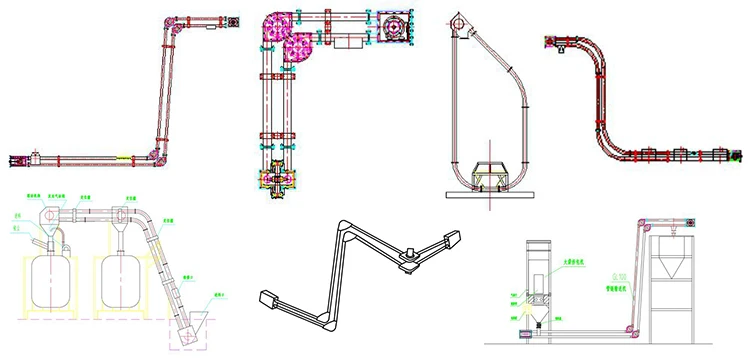

The Chain Conveyor,alsocalledplatechain conveyor,is a mechanical system that operates in a seal pipe.Its feature is the stable property and saving the energy consumption in conveying system.It can contiguously conveybulky material, such aspowder,fineparticle and small lump and so on. Itcan convey in the level,the incline and the vertical.It widely applies in the chemical industry,the chemical fiber,the agricultural chemicals,ore,the food industry,thebuilding materials,ect..

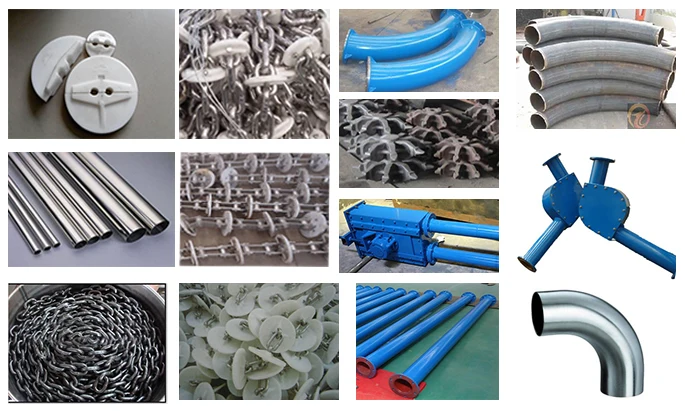

Mainstructure ofchainsconveyer

1.Active part(handpiece)

1)motor reducer2)drive sprocket 3)box 4)bearing 5)seal

2.Middle nodule

The middle pipe(including frange)

3.drivepart

1)chains2)discs3)wall-cleaning device

4.The turning part

1)steering gear:the steering body,steering wheel,bearing block 2)The big bend(turn the elbow)

5.Inlet and outlet

(depend on certain requirement)

6.The passive part

1)the driven sprocket 2)passive box 3)Tensioner4)bearing 5)seal

Technical parameter

|

Model |

conveyingcapacity (m³/h) |

Sprocket speed (r/m) |

Chainsline speed (m/s) |

Power of motor (kw) |

|

GL80 |

4 |

20 |

0.29 |

4 |

|

GL100 |

8 |

18 |

0.31 |

5.5 |

|

GL150 |

16 |

15 |

0.31 |

7.5 |

|

GL200 |

28 |

12 |

0.3 |

11 |

|

GL250 |

48 |

10 |

0.3 |

15 |

|

GL300 |

60 |

8 |

0.28 |

18.5 |

|

GL400 |

80 |

8 |

0.28 |

22 |

Technology advantage

1.Scientific Design--Inchain conveyor design, we have anti-off chain device and chain-brokenprotection device, matching color disc, the chain reverse recognition; add emergency outlet toensure resume production rapidly.

2.Perfect Service--Have rich experience on manufacturing and installing. There are enough spare parts.

3.Rich Experience--Boyang chain conveyors haverich experiencebased on being use in most industriesandtreatwidest range materials. Max Capacity is 300m³/h.Vertical conveying length up to 40 m,and horizontal conveying length up to 60 m.

4.PowerfulStrength--Boyang Machinery Company is strong in technology andestablished research base with universities. It has two research centers. It is high-new-tech enterprise with more than 30 engineers and technicians.

5.Advanced Technology--Advanced control system,with online status detection system,could timely alarm interlock in the case of abnormal running to avoid equipment accidents.

6.Excellent Performance--The sofe disc could bear high temperature up to 250℃.The system could working at 500℃.

|

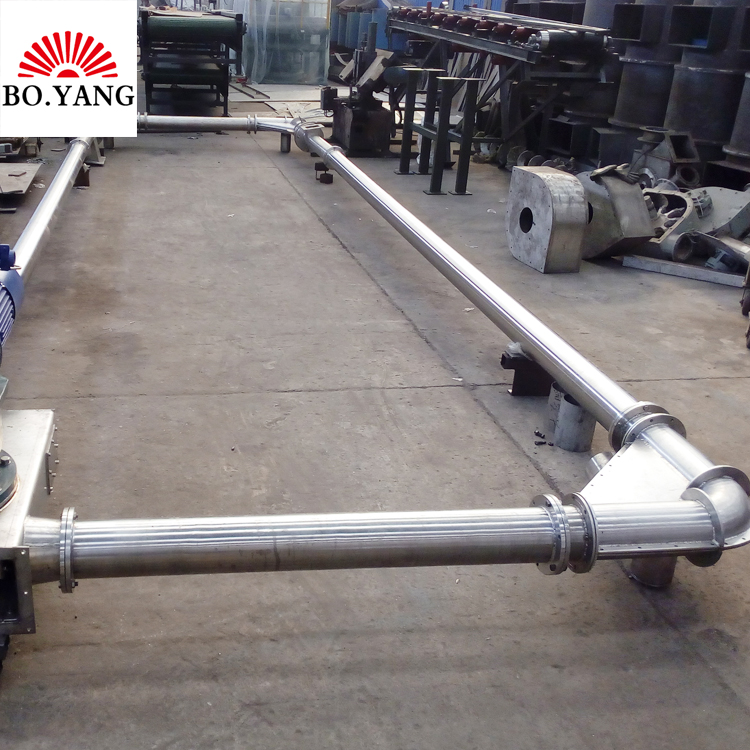

1.Ring chainsconveyor

|

1.Compact structure: changetransport direction of the three-dimensional. 2.Fully enclosed transport, no dust spills, clean and environment friendly. 3.Lowest energy consumption, maximum lower operation cost during material conveying. 4.Maximnm conveying: 60m horizontal and 40m vertical,Maximnm capacity:300 m³/h 5.No dead area 6.No metal friction and lowest noise 7.Low maintenance costs 8.Longservice life 9.Explosion and pressure shock resistant design 10.Can start with load. 11.Minimal ensure material integrity. |

|

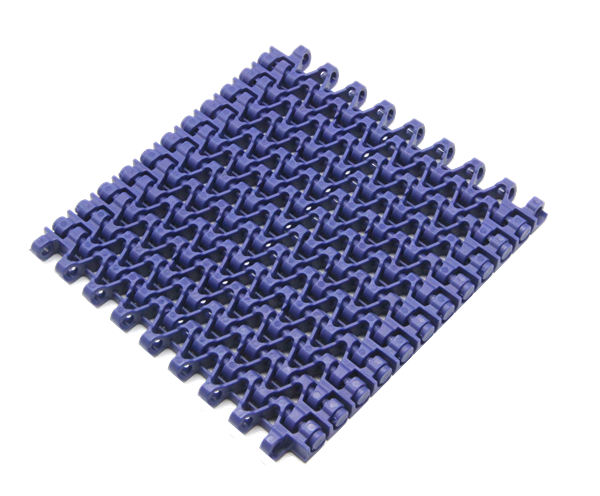

2.Plate chain conveyor

|

1.Simple structure, Horizontal curves 2.The overall structure of the chains 3.Stable drive. 4.High strength and wear-resistance 5.Rolling friction ,reduce friction coefficient 6.Convenient dismounting |

|

3.Steel wire rope conveyer

|

1.Compact structure, Can be universal turning 2.No dead area 3.discharge at multiple points; no special airlocks 4.adjustable plate spacing 5.Suitable for small capacitymaterial conveying 6.Cheaperthan the plate chains, chains 7.Low maintenance cost |

- Pesticides & ORE

|

Pesticides & ORE |

||||

|

Urea |

Phosphate rock |

Molybdenum oxide |

Tungsten powder |

Molybdenum(LV)sulfide |

|

Carbamide |

Glass powder |

Alumina powder |

Ammonium chloride |

Ammonium bicarbonate |

|

Silica fume |

PET molybdena |

Molybdenum oxide |

Titanium concentrates |

copper concentrate powder |

- Chemical lndustry

|

Chemical lndustry |

||||

|

PP |

Sulfur |

Bentonite |

Fiberglass |

Lithum carbonate |

|

PE |

Coke |

Uranium |

Carbon black |

Sodium fluride |

|

PTA |

Kaolin |

Uranium |

Caprolactam |

Barium hydroxide |

|

BPT |

Zeolite |

Ferric oxide |

Heavy calcium |

Potassium fluride |

|

POM |

Breeze |

Caustic soda |

Light calcium |

Calcium carbonate |

|

ABS |

Paints |

Lan carbon |

Sodium chloride |

Aluminium hydroxide |

|

PVC |

Coating |

Oxalic acid |

Lignit powder |

Activated carbonate |

|

Dyes |

Titanium |

Adipic acid |

Titanium pigment |

|

- Food lndustry

|

Food lndustry |

||

|

Sugar |

Cereals |

Food Additives |

|

Starch |

Milk powder |

Chinese herbal medicine residue |

- Building Material

|

Building Material |

|||

|

Silica |

Glass fiber |

Clay powder |

Talcum powder |

|

Cement |

Quartz sand |

Pottery clay |

Limestone powder |

|

Dolomite |

Yellow sand |

Wood powder |

Silicon dioxide |

The relative parts

Other applicaions

Packaging:

Machine packing inside is plastic films and outside is fumigation wooden case.Our wooden case is very strong,it can bear long time shipping on the sea.And machine with preservative film,it can stop the salt sea water enter into the machine and make the machine corrosion.

Shipping:

Upon receipt of payment , delivery date will be in 3-15days

By Air, by Sea or by Express (DHL etc)

Shipment cost will depend on the destination, shipment way,size and the weight of the goods.

Warranty period & After service

Life-time warranty.

Any problem caused by our party within one year from the date of shipment, we will provide free spare parts for the repairment.

After one year, we can provide the spare parts, but the user should pay for the related cost, including cost of the spare parts, delivery cost etc.

As request, we can send our professional engineers to your factory to set up the machine and training your workers , only need you to bear relate charges. and any question you meet when using, you can contact me at any time by Skype or cell or , we will respond you within 12 hours

1. Pre-sale: we given client the details technician offer, sign the sales contract etc.

2. In-sales: we supply the details layout, installation instruction, technician support for the clients.

3. After sales: we arrange engineer to install the machinery and training the workers for client.

4. We have 24hours team to solve the after sales problem.

5. We have free spare parts with the machine.

6. We supply long term spare parts for every customer.

7. We always up date the new technology to every customer.

is a professional manufacturing of machine of packaging,conveying,logistics and warehousing for powders,graniles,pastes,and other materials.we have passed ISO9001 quality management system certification.

Our products if suitable for industry of cement,coal,chemical,plastic,feed and rubber,especial evident for the Non-metallic mineral power,ultra-fine power,Nano powder and powder packaging industry.Our product are small-bag packing machine,ton-bag packing machine,bulk machine ,powder packing machine,pumping vacuum packaging machine,lifting machine,chain conveying machine and bag-unpackaged machine.

For more infomation plz contact us:

Send product request

Other supplier products

| Widely used 25kg bag breaker | BoYang Automatic Bag opener machine Production Flow Automaticbag-cutter is comprised of seven parts,belt feeder,bag-cutting device,screeningd... | |

| competitive price BY Break the 25kg bag machines | competitive price BY Break the 25kg bag machines BagOpening machinery,sometimes called manual bag-unpackaged machineor bag emptying.Ithasdust filt... | |

| BOYANG Universal DC-type Baling press | BOYANG DC-type Baling press Product Description Basic Principle: The machine uses linear feeding mode, two-level control valve, discharge by... | |

| Automatic plastic big bag sealing cutting machine | plastic big bag sealing cutting machine Ton-bag breaker also named big bag split machine, ton- bag unloader, bulk bag dumping station, ton-bag fee... | |

| Automatic Valve Bagging machine with powder | valve pouch packing machine Application Scope valve pouch packing machineSuitable for material of particle size 100-300 mesh with larger prop... |