3 Rolls Plate Bending Machine

EZHONGis located in the ancient city of Wudu - Ezhou City, Hubei Province. It is one of the heavy forging and shaping equipment enterprises designated by the former First Machinery Department to produce plate bending rolling machines and plate straightening machines. It is a manufacturing company with an independent legal personality established after reform, reorganization and restructuring.

The CNC 3 roll bending machineadopts the structure of the lower cylinder. The upper working roller of this machine is the main driving roller: the upper roller is driven by a hydraulic motor (a motor) through a planetary reducer to drive the upper roller to rotate, and the two lower rollers are respectively driven by a hydraulic motor planetary reducer to drive the lower roller to rotate. The lifting of the upper roller is realized by hydraulic cylinder, the lifting displacement is controlled by computer, automatic leveling, screen display, synchronization accuracy ±0.2mm; the horizontal position of the two lower rollers can be adjusted separately, the horizontal movement adopts hydraulic transmission, the center distance can be adjusted; the side lower roller bearing seat is equipped with a cone stopper to slow down the small end of the sector plate to achieve a certain range of cone rolling; the general cone angle is 30°, 50% of the full load.

The tail of the upper roller is equipped with a balance mechanism, which can facilitate the unloading of the rolled workpiece and the cylinder. The three roller pipe bending machineis equipped with a fixed console and a remote control button box, which are convenient for workers to use. Equipped with safety interlocking device to make the operation safer. The machine has simple operation, convenient maintenance and high rolling precision. It is an advanced and practical large-scale rolling equipment.

Working Principle Of 3 Rolls Bending Machine

lThe controlled movement of the lower roller makes the pre-bending operation very easy.

lThe reduction of the distance between the lower rollers can better drag the plate, which facilitates the subsequent bending of products with smaller diameters and thicknesses, and facilitates the measurement of curved plates that must be welded.

lIncreasing the distance between the lower rollers makes it easier to bend thick plates.

During pre-bending, the steel plate is kept in a horizontal position, which ensures better safety conditions for the operator.

Due to the upper profiled roller operating system, the 3 roll bendingmachine can be used as a traditional press to perform pressing and measure the finished product.

In the same way, very thick cone plates and curved plates can also be produced through different pressing operations.

Advantage of EZHONG 3 Rolls Bending Machine

lHigh-precision end of the pre-bending, set the length of the straight edge freely; direct pressure on the pre-roll bending, high-precision can be completed in advance of the end of the bend.

lCNC control, high productivity products rolling process parameters NC, a simple and substantial increase inefficiency.

lThe roller assumes the bulging form on products accuracy hyper group, have asking a roller to coordinate adjustment, continuous bending on time of roller lower part, this one broad range inner is able to make ideal products roll from lamina to plank.

lOperating under the security of two fixed roll, roll up and down on, move around, do not work with mobile work roll, operations safely.

As one of the 3 roller bending machine manufacturers, EZHONG provides high quality 3 roller bending machine for sale, we also provide a good 3 roller plate bending machine priceand 3 roller bending machine pricefor customers.

Send product request

Other supplier products

| Plate Rolling Machine For Tank | The upper rollers of the machine can be moved vertically and horizontally. The vertical lifting is the hydraulic transmission. The hydraulic oil in... | |

| Plate Bending Machine | The metal plate bending machineis forging equipment used to bend metal plates. It is dedicated to the forming and bending work of metal plates. Thi... | |

| Plate Bending Machine | The plate bending machine chinais forging equipment used to bend metal plates. It is dedicated to the forming and bending work of metal plates. Thi... | |

| Second Hand Metal Forming Machine | EZHONGhas accumulated rich experience in the manufacturing of plate bending rolling machines such as large-scale horizontal 3 roll bending machine,... | |

| W43B Leveling Machine | EZHONG W43B leveling machine adopts a straightening roller layout design of six upper and lower seven. If you need to add straightening rollers, yo... |

Same products

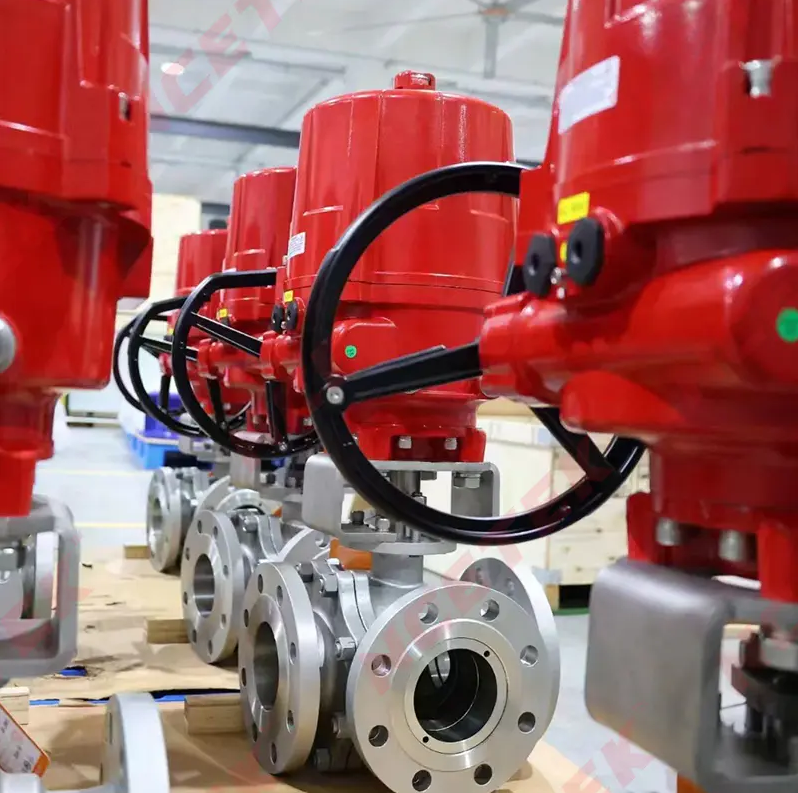

| Three-Way Ball Valve Factory In China | Seller: Zhejiang Naishi Valve Co. | Technical Specifications◎ Design Standard: API6D, ASME B16.34, GB/T 19672, etc.◎ Material: Carbon... | |

| Qianli Super Camera Ai Gorilla 4K Camera with Barlow Lens Kit | Seller: PHONEFIX technology Co.,Ltd | The core function of the kit is to provide ultra HD, wide field of view, long working distance of... | |

| Displacement Sensor 6000TDGN Raj West Lignite power | Seller: Dongfang Yoyik Engineering Co., Ltd | YOYIK has been focusing on the field of industrial spare parts for more than 30 years. With its e... | |

| Calcium ingot chip cutting machine | Seller: Puyang Mingli Petrochemical Machinery Manufacturing Co., Ltd. | We have calcium ingot chip cutting machine and aluminum ingot granulation and powder production l... | |

| Hirschmann MACH102-8TP 943 969-001 Switch | Seller: 840499 | The MACH103-8TP is a fanless 19-inch rack mount Managed Modular Fast Ethernet Layer 2 Industrial ... |