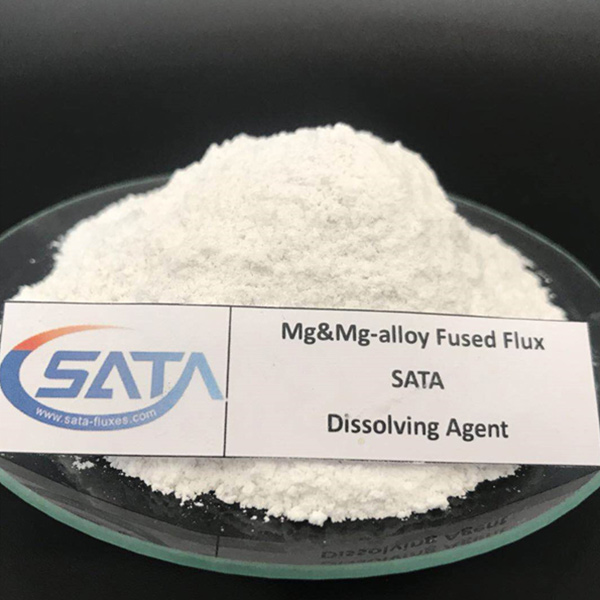

Mg Alloy Flux

Magnesium alloyfluxhas a low melting point and small heat capacity. When heated in the air, it gets oxidized fast, and it is easy to burn when overheated. When in a melting state without any flux, it can be burned violently. Therefore, the magnesium alloy must always be in flux or protective atmosphere during the casting process. The quality of molten casting depends greatly on the quality of the flux and the melt protection.

Other supplier products

|

|

Magnesium Chloride Hexahydrate Flake |

Magnesium Chloride Hexahydrate Flake

General Description of Magnesium Chloride Hexahydrate Flakes

Chemically, magnesium chloride is represented as ... |

|

|

Fluxes for Magnesium Alloy |

Magnesium alloy has a low melting point and small heat capacity. When heated in the air, it gets oxidized fast, and it is easy to burn when overhea... |

|

|

Ti Tablet |

Ti Tablet

General Description of Ti Tablet

Titanium Tabletis used to adjust the content of Ti content in Aluminium Alloy, it is made by metal powde... |

|

|

Sodium Fluosilicate/Hexafluorosilicate (SSF) |

Sodium Fluosilicate/Hexafluorosilicate (SSF)

General Description of Sodium Fluosilicate/Hexafluorosilicate (SSF)

Molecular Formula:Na2SiF6

UN NO.: ... |

|

|

Covering Flux |

General Introduction:

Chemical formular: Mgcl2 6H2O

Purity: 46.00%min.

Appearance: pure white crystal power

CAS NO.:7791-18-6

Chemically, is repr... |

All supplier products

Same products