Exceptional Robot Fiber Laser Welding Machine

Description

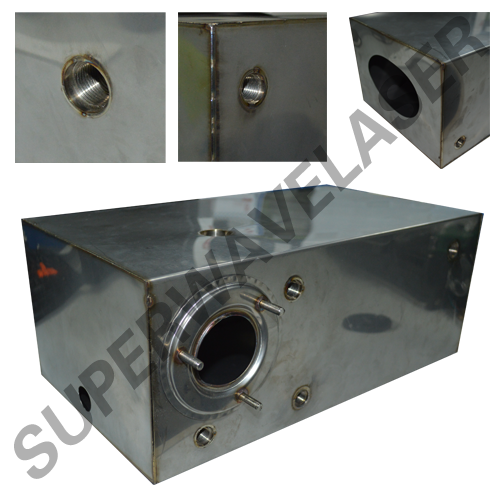

Robot manipulatorfiberlaser welding machineis a laser welding equipment which couples the high energy laser beams into the optical fiber, after long-distance transmission, then transformed into parallel lights through collimating mirror tobe focused on the work piece to implement the welding.

It’s more flexible to implement flexible transmission of non-contact welding for those difficult to weld site. The laser beam can realize the spectrum separation on time and energy, can be multi-beam processing at the same time, for more precise welding provides the conditions.

Advantages

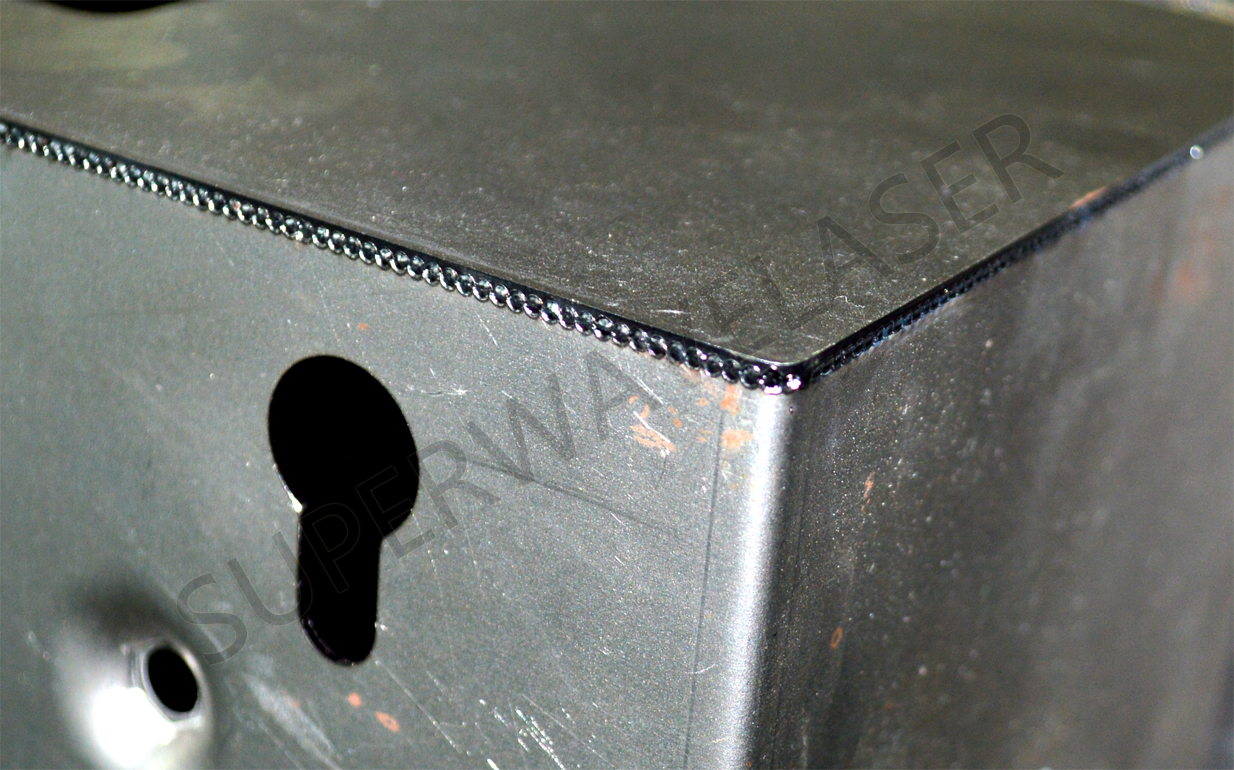

►Imported 6-axis linkage of high-precision robot welding system, with our energy closed-loop (energy negative feedback) laser welding machine, laser energy output stability, energy closed-loop real-time monitoring, automatic compensation, so as to ensure the consistency of the welding energy;

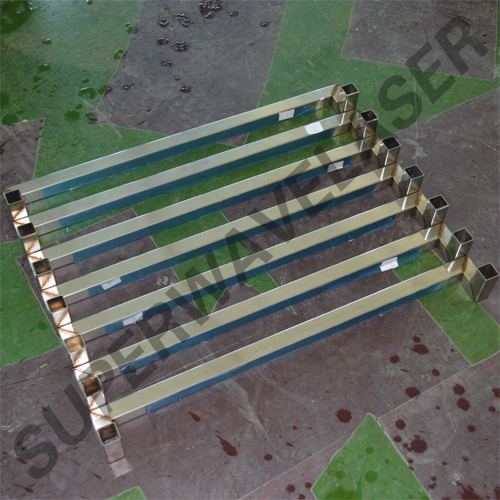

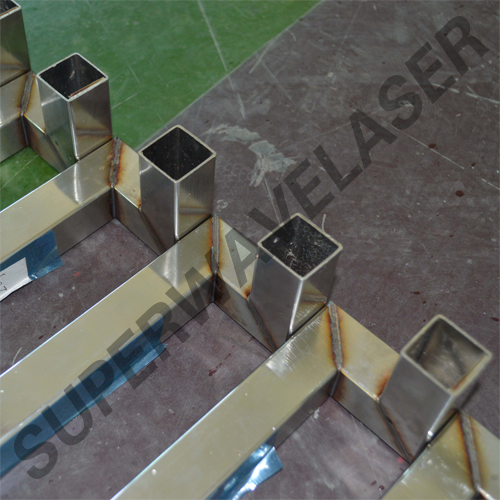

►High yield, laser head in the space moverandomly, easy alignment, only a simple fixture to complete the difficult welding of special-shaped parts;

►Multiple stationscan be setto facilitate loading and unloading, thus improving welding efficiency;

►Lowest deformation due to heat conduction;

►No electrode pollution or damage concerns; Non-contact welding work, welding head wear and deformation can be minimized;

►Weldinghead can be placed on the artifacts at the appropriate distance,reducing the range of space constraints;

►Artifacts can be placed in a closed space (by vacuum or internal gas environment under control)

Application

Welding and brazing, protective gas welding, other welding, brazing, painting, surface treatment, and other applications. Applicable to microelectronic components, precision parts, high-grade digital components, fiber optic connectors, medical equipment, large-scale mold welding, injection molding and other welding.

Weldable material: carbon steel, ordinary alloy steel, stainless steel, laser welding ofdifferent steels, stainless steel - low carbon steel, 416 stainless steel -310 stainless steel, 347 stainless steel -HASTALLY nickel alloy, nickel electrode - cold forging steel, different nickel content of bimetal strip, titanium, nickel, tin, copper, aluminum, chromium, niobium, gold, silver and other metals and their alloys, and steel, Kovar alloy and other alloys ofthe same material.

Shenzhen Superwave Laser Technology Co., Ltd is one of the world’s leading high-tech laser equipment manufacturers which included R & D, research and development, production and sales department. With more than 10year experience of research and development, production of laser industrial equipment, some products have passed the international CE certification and exported to the United States, Britain, Singapore, Japan, Taiwan, Korea, Malaysia, Thailand, Australia and other countries of the world, reliable quality and enthusiastic service has been widely recognized by customers.

Superwave set up the marketing management, production and R & D center in ShenzhenChina, focusing on the forefront of the world's high-tech information technology, the company gathered a group of innovative spirit and professionalism of the technical talents in the field of laser technology research and development and application, constantly digestion and absorption of European and American laser technology and production management experience, Superwave uphold the spirit of "Sustainable research and development, Pioneering and innovative, Excellence", after more than 10 years of technical precipitation and experience accumulation, Superwave has become one of the few domestic master "Energy Closed-loop Welding System" "3D Relief Technology"; "3D Welding Technology"; "3D Cutting Technology"; "3D Dynamic Focusing Marking Technology"; "Pipe Cutting"; "Metal Precision Cutting"; "Fragile Material Laser Cold Processing Technology"; "Robot Welding Cutting"; "Flight Marking"; "Visual Recognition and Positioning System"; "Closed Loop Control Data Chain Information Chain Image processing"; "Scanning Welding Technology”and other core technology of the national high-tech laser technology enterprises.

Send product request

Other supplier products

| High Efficiency Spot laser welding machine | Features 1.The energy, pulse width, frequency and light spot size can be adjusted in a large range to realize different welding effects. The param... | |

| Paramount Mobile Laser Welding System | Description This is fiber optical laser welding system, the high power laser beam delivery by an optical fiber, so it's ensure to do the long dista... | |

| Superfine CO2 laser marking machine | Description CO2 laser marking machine is the gas marking machine, its wavelength is 10.6um which belonging to the infrared band.CO2 laser machine ... | |

| High Standard UV laser marking machine | Description Ultraviolet laser has less thermal effect by comparing with green laser and infrared laser. Various materials have high absorption rate... | |

| High Accuracy Mobile Laser Welding System | Description This is fiber optical laser welding system, the high power laser beam delivery by an optical fiber, so it's ensure to do the long dista... |

Same products

| Ferrite Block Magnets | Seller: Hangzhou Tengye Magnetic Materials Co., Ltd. | Block ferrite magnetsare a type of permanent magnet made from a mixture of iron oxide and barium ... | |

| CUSTOM HIGH DENSITY GRAPHITE ROD | Seller: Pingdingshan Wanhui Graphite Co., LTD | WH conductive graphite roduses graphite block as raw material. After the processing of profession... | |

| Round Magnet N52 1/2 inch x1/8 inch Small Flat Magnet Disc | Seller: Huatai Xinding(Beijing)Metal Materials Co., Ltd. | This powerful small neodymium magnetsmeasures 1/2" in diameter, 1/8" in thickness, with the pull ... | |

| Magnetic Assemblies | Seller: Huatai Xinding(Beijing)Metal Materials Co., Ltd. | Magnet assemblyincorporates magnet alloy and non-magnet material, usually creating much more magn... | |

| Lead free Brass Rod | Seller: Ningbo Jintian Copper (Group) Co., Ltd., | Jintian is a leading manufacturer of high-quality lead free brass rodbased in China. The company ... |