Professional Fiber Optical Laser Welder Energy Feedback Type

Description

Our company is one of the few domestic professional laser welding company covering the whole field of welding applications, and thelaser output poweris from 5watts to 5000 watts. The key technologyof our company is theenergy negative feedback control for arbitrary waveform, details as follows:

1) Energy negative feedback control

The energy negative feedback control is to compare the output laser energy waveform with the actual output energy waveform in real time to determine the energy input of the pump lamp and then control the output energy. With the energy negative feedback control technology, the laser output energy can be accurately controlled within 2% range. At the same time, the following problems can be solvedwhich can lead to large fluctuations of laser output energy:

1-1) Thefluctuation of city electricity.

1-2) The difference of each discharge of xenon lamp.

1-3) The reduction of output laser energy caused by xenon lamp aging.

2) Arbitrary waveform setting

In the processing of production, for copper, aluminum, gold and other materialsas itshave a high surface reflectivityfor the 1064nm wavelength laser, resulting in the processing have strength is not enough, welding surface is notbeautiful and other issues; for high-carbon and other materials, hot cracks, cold cracksand other issues occur in the process due to rapid quenching and rapid heating. For the above problems, by changing the energy fluctuation of the laser pulse to control the change of the laser energy during the welding process, the above problem is solved by using the method to achieve the best welding effect.

Advantages

► Optional CCD camera monitoring system, easy to observe and precise positioning.

► Uniform energy distribution of welding spot, the best spot needed for welding characteristics.

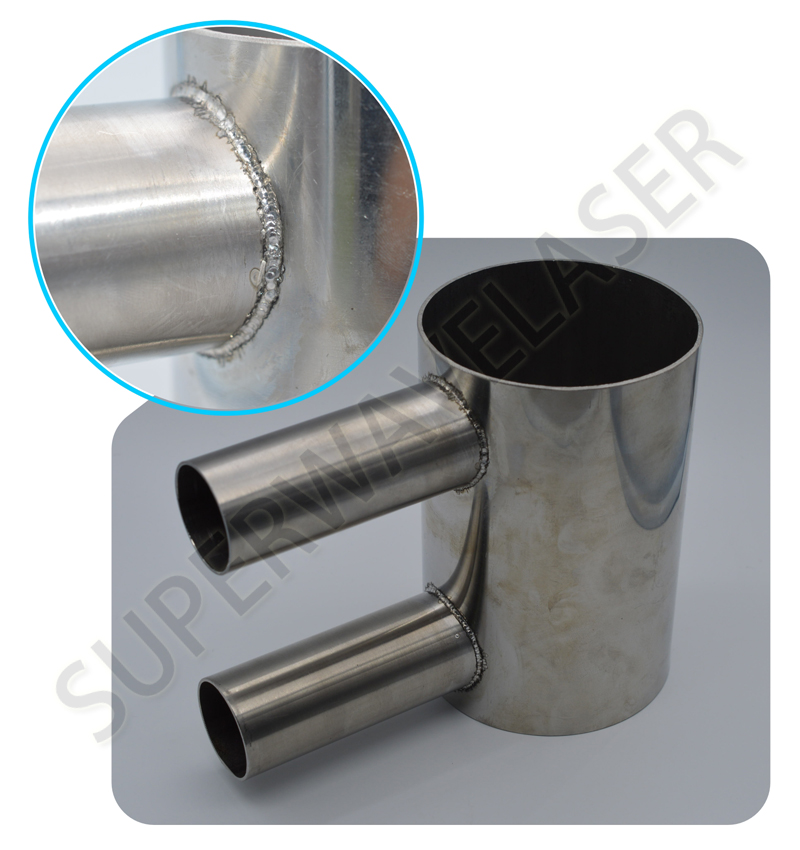

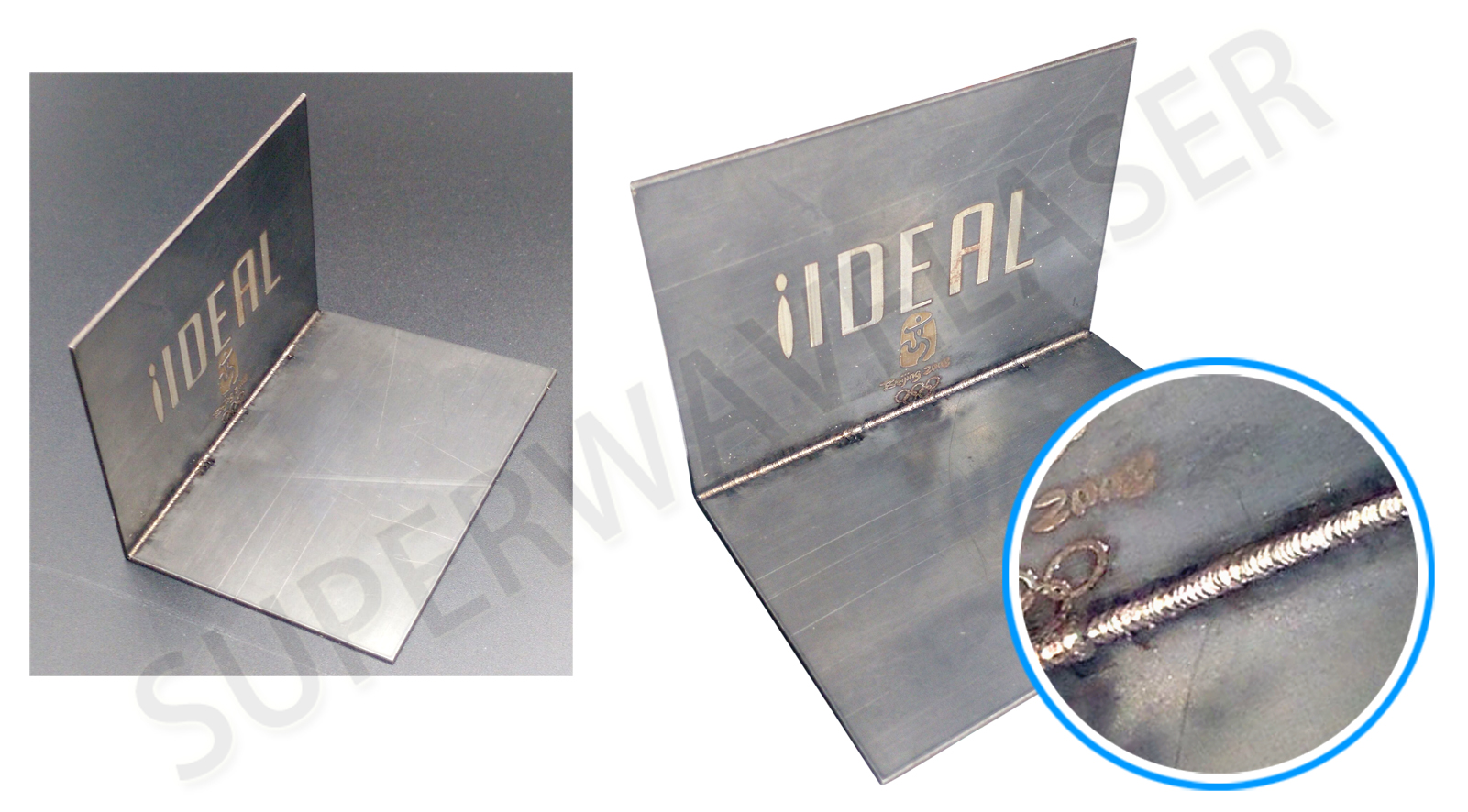

► Adapt to a variety of complex welds, spot welding of various devices, and within 1mm sheet of seam welding.

► Customized automatic fixture for mass production.

Features:

► Imported gold cavity, corrosion resistance, high temperature resistance, life 8-10 years, xenon lamp life’s more than 800 million times.

► Non-contact processing, stress free, noiseless, no pollution to the environment, which belongs to the green processing.

► High laser energy density, small thermal effect area, not easy deformation, less or no subsequent processing.

► Easy spot welding, stack welding, splicing and continuous welding.

► Good quality laser beam, high conversion efficiency and therefore high welding speed, high aspect ratio, high strength.

► Good welding quality, smooth and beautiful appearance.

► Solder joints non-pollution, weld strength and toughness at least equivalent to or stronger than the base metal.

► With energy negative feedback control function, the laser energy instability caused by the fluctuation of the grid, the aging of the xenon lamp and the change of the water temperature is eliminated, and realized the stable and high-quality welding processing. It is especially suitable for welding high reflectivity materials such as copper and aluminum.

Application

Laser welding can be used in welding stainless steel, aluminum, copper, gold, silver, chromium, nickel, titanium and other metals or alloys, can also be used for a variety of welding between different materials, such as: copper - brass, titanium - gold, Titanium - molybdenum, nickel - copper and so on.

Laser welding is widely used in the IT industry, medical equipment, communications equipment, aerospace, machinery manufacturing, battery manufacturing, elevator manufacturing, craft gifts, household appliances manufacturing, tooling, gears, automobile shipbuilding, watches and clocks, jewelry and other industries.

Shenzhen Superwave Laser Technology Co., Ltd is one of the world’s leading high-tech laser equipment manufacturers which included R & D, research and development, production and sales department. With more than 10year experience of research and development, production of laser industrial equipment, some products have passed the international CE certification and exported to the United States, Britain, Singapore, Japan, Taiwan, Korea, Malaysia, Thailand, Australia and other countries of the world, reliable quality and enthusiastic service has been widely recognized by customers.

Send product request

Other supplier products

| Best Selling Fiber laser marking machine | Description Fiber laser marking machine: The optical fiber laser markers feature high efficiency in electrical/opticalconversion, and wind cooling... | |

| High Efficiency Mobile Laser Welding System | Description This is fiber optical laser welding system, the high power laser beam delivery by an optical fiber, so it's ensure to do the long dista... | |

| Professional Mobile Laser Welding System | Description The mobile laser welding system, it's suitable for welding large size mould, which is heavy and difficult to move. The MLW laser welder... | |

| High Efficiency Laser Mould Welding Machine | Description This is laser mould welding workstations specialized for mould repair, for the all tooling steels; With our laser welding system we can... | |

| High Standard Fiber laser marking machine | Description The optical fiber laser markers feature high efficiency in electrical/opticalconversion, and wind cooling is employed. The whole system... |

Same products

| Portable Handheld Fiber Laser Welder – Water Cooling for Industrial Use | Seller: Beijing JCZ Technology Co., Ltd | This portable handheld fiber laser welderis designed for industrial-grade welding operations. It ... | |

| MEDIUM FREQUENCY WELDER | Seller: NINGBO XIHE AUTOMATION EQUIPMENT CO.,LTD | The single-rib brake shoe seam frequency welding machineadopts intermediate frequency welding tec... | |

| LONGITUDINAL SEAM WELDER | Seller: NINGBO XIHE AUTOMATION EQUIPMENT CO.,LTD | Xihe automatic longitudinal seam welding machineis the most versatile aluminum seam welder on the... | |

| High Efficiency Laser Welding Machine OEM laser welding Machine price aluminium laser cutting machine manufacturer | Seller: Jinan MYST Laser Equipment Co., Ltd. | High Efficiency Laser Welding MachineOEM laser welding Machine price aluminium laser cutting mach... | |

| Advanced Laser Spot Welder | Seller: Shenzhen Superwave Laser Technology Co.,Ltd | Features 1.The energy, pulse width, frequency and light spot size can be adjusted in a large ran... |