China Top 1 Laser Spot Welding Machine for Jewelry

China Top 1 Laser Spot Welding Machine for Jewelry

Description

The Laser spot welder give extraordinary quality of laser welded joints from a machine that is quick and easy to use. Within a few minutes spot and seam welds can be realized with an accuracy in the micron range - even in complicated areas. The rule of thumb is: if you can see the joint, it can be laser welded. With a laser, experienced users can join filigree work-pieces with a fineness and precision which no other method can even remotely achieve.

Advantage

Laser welded joints are of high strength and resist even high mechanical strain without any wear. Other than adhesive seals, they are temperature-resistant and show pore-free surfaces. Compared to other joining techniques, post processing of laser weld is reduced to only a few simple steps,or can be ignored completely.

1.High flexibility:Perfect welds - even in complicated areas

2.High Precision:Spot-accurate positioning and visual control via stereo microscope

3.Minimal heat input:No distortion, no damage to temperature-sensitive components

4.Micro welding:Weld seams smaller than 50 microns with high pulse-to-pulse stability

5.Filigree and robust:Welds of 50 micron to 2 mm seam depth

6.Multifunctional:Spot, seam, overlap and deposit welding

Features

By matching the parameters and shape of the laser pulses to each material, the laser generates a minimal heat affected zone, thus meeting the precondition for welding temperature-sensitive components. Another positive effect of the low thermal load of the two parts is, that unwanted modifications of the joint by the welding process can almost always be avoided.

1. Smaller size, save space.

2. Internal water to air cooling. No shake.

3. High performance laser beam quality, flat-top laser beam shape. No spatter, no dark, smooth spot.

4. High stability laser energy output.

5. Stable power supply system ensure 24hours running.

6.The energy, pulse width, frequency and light spot size can be adjusted in a large range to realize different welding effects.

Application

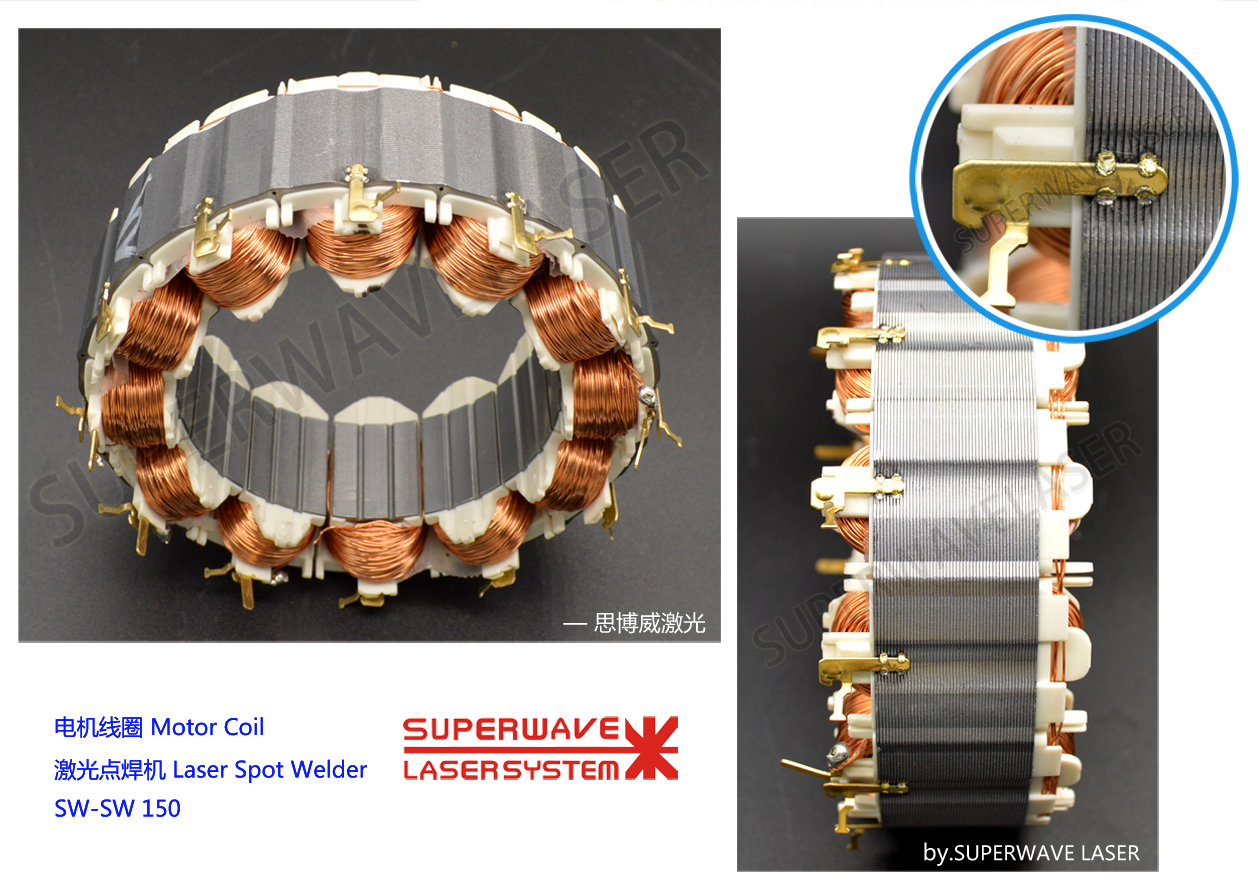

K-Gold, brass, Stainless steel, and their alloys. It is mainly used for manufacturing and repairing jewelries, as well as precisely welding a variety of micro and heat-sensitive parts, just like nickel straps of batteries, hairsprings, watch components, down-leads of chips.

Laser spot welder is mainly use in jewelry and dental industry or other hardware field. This kind of machine can process all metallic material, which used for making jewelries such as gold, silver, platinum, titanium, palladium, K-Gold, Stainless steel, and their alloys. It is mainly used for manufacturing and repairing jewelries, as well as precisely welding a variety of micro and heat-sensitive parts, just like nickel straps of batteries, hairsprings, watch components, down-leads of chips.

Product Parameter

| Model |

SW-SW40A |

SW-SW60A |

SW-SW100A |

| Laser medium |

Nd:YAG |

| Wavelength |

1064nm |

| Max. output power |

40W |

60W |

100W |

| Max. pulse energy |

30J |

60J |

100J |

| Peak pulse power |

4KW |

5KW |

7KW |

| Pulse duration |

8ms |

12ms |

15ms |

| Pulse frequency max |

5Hz |

1-15Hz |

1-15Hz |

| Focal diameter |

0.2-2.0mm |

| Cooling system |

Internal cooling system |

| Vision system |

Stereo microscope 10X,CCTV camera system optional |

| Program memory |

100set |

| Power supply |

AC220V/1Ph/50Hz or 60Hz.16Amp |

| Net weight |

50kg |

60kg |

65kg |

| Dimensions |

L:900mm,W:505mm,H:500mm |

TEST SAMPLES VIDEO:

Other supplier products

All supplier products

Same products