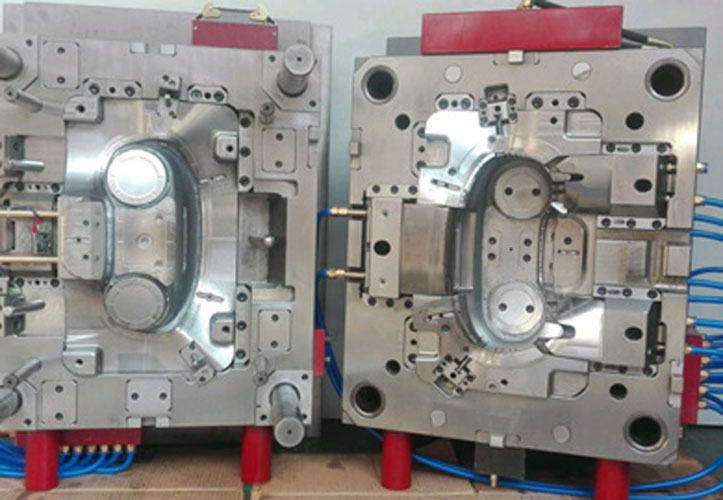

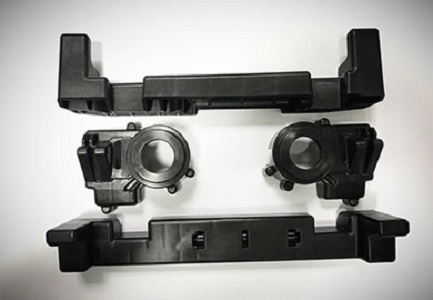

Insert Mould

Insert molding is a precision injection moldingprocess used to encapsulate a component in a plastic part.

The insert plastic injection molding process can be divided into two basic steps. First, the component is loaded into the mold before the molding process. Second, it takes the shape of the part and locks the component into the plastic as molten plastic is injected into the mold.

Features of Insert Mould

Insert molding is the process of inserting a part into a mold prior to the injection molding process. Since the insert injection molding process is the same, different materials are fed into the mould so as to produce different mould products. The main features of using insert mould by GM-TECH, a reliable injection moulding manufacturer, include:

Improved strength

A strong and reliable attachment point for inserts

Cost-effective compared with other inserting processes

No significant mold changes required

The Specification of Insert Mould

|

Part material |

ABS |

|

Cavity |

1 |

|

Mold accuracy |

+ / - 0.02 |

|

Mold steel |

H13 |

|

Moldbase steel |

|

|

Mold life |

100W |

|

Mold standard |

HASCO |

|

Mold structure |

3 slides |

|

Exporting country |

Germany |

|

Leadtime |

4 weeks |

|

Mold quality customer satisfaction |

98% |

|

FAI pass rate |

96% |

|

Project cooperation service customer satisfaction |

98% |

How does Insert Mould Work?

Insert molding is a powerful tool used to support the form and function of plastic injection molded parts. Insert molding refers to incorporating other parts, particularly metal parts, directly into the injection-molded product.

For instance, if there are metal inserts that we need to paste it to plastic. We need to place the metal inserts into the insert mold before injecting the plastic. The inserts will be surrounded by the plastic during the injection process, leaving the insert bonded firmly to the material after cooling and curing.

If you want to know more about mold technology, please contact us.

Send product request

Other supplier products

| Die Casting Mould | Die casting mould is a method of casting liquid die forging. It is a process completed in a special die casting moulding machine. The major adva... | |

| Die Casting Mould | Die casting mould is a method of casting liquid die forging. It is a process completed in a special die casting moulding machine. The major adva... | |

| 2K Mould | GM-TECH, injection moulding manufacturers,has been manufacturing tools for injection molding of plastics for various industries for more than 10 ye... | |

| 2K Mould | 2k injection mouldingis a manufacturing process that refers to molding two materials or colors into one plastic part. This technology combines t... | |

| Electronics Product Part | With the fast growth in the electronic industry, the demand for injection molding electronics is much higher. The injection molding electronics can... |

Same products

| Zbk03 Series Roots Vacuum Pump/Roots Pump | Seller: Greentech International (Zhangqiu) Co., Ltd | ZBK series roots vacuum pump is a kind of coarse vacuum acquisition of equipment, it is widely us... | |

| Quick-response Mechanical seal M74N-140 for power generation | Seller: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | "Quick-response Mechanical seal M74N-140 for power generation Is YOYIK for the use of turbine uni... | |

| "High-reliability Support ring Y10-4 for power station | Seller: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | "High-reliability Support ring Y10-4 for power station Deyang YOYIK have power plant professional... | |

| "Wear Resistance dn50 globe valve WJ25-F1.6P for thermal power plant | Seller: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | "Wear Resistance dn50 globe valve WJ25-F1.6P for thermal power plant YOYIK professional productio... | |

| High-efficiency Superheater outlet plug valve SD61H-P61305V SA-182 F92 for power generation | Seller: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | "High-efficiency Superheater outlet plug valve SD61H-P61305V SA-182 F92 for power generation Deya... |