Tapered Roller Bearing

Tapered roller bearing, which is produced by THB, a tapered roller bearing supplier, have tapered inner and outer ring raceways and are configured with tapered rolling elements. This design can withstand the simultaneous action of combined axial and radial loads. The followings are the tapered roller bearings for sale.

Single Row Tapered Roller Bearing

Designed to bear radial load and axial load in one direction. There is a set of tapered roller and cage assembly in this bearing.

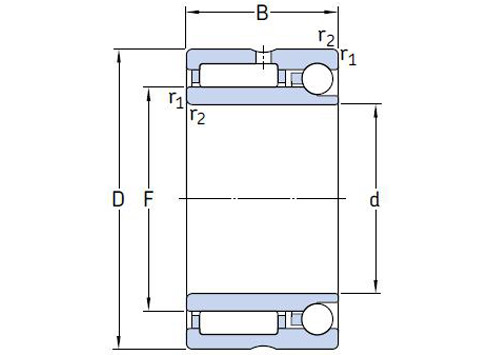

Double Row Tapered Roller Bearing

It consists of two inner rings with single-row raceways, an outer ring with double raceways, and two sets of cage tapered roller assemblies. Generally, there is a spacer ring between the two single-race inner rings. Or it is composed of two outer rings with single raceways, one outer ring with double raceways and two sets of cage tapered roller assemblies. Generally, there is a spacer ring between the two single raceway outer rings.

Four-row Tapered Roller Bearing

Four-row tapered roller bearing can bear heavier axial loads in two directions, and can adapt to combined (radial and axial) loads of low and medium speeds.

Key Features of Tapered Roller Bearing

Low friction - The roller end face and the baffle are optimally designed, and the baffle guide surface is polished to reduce its roughness, thus promoting the formation of lubricating oil film and reducing friction. It also reduces the wear of the retaining edge. Preload is better maintained and noise levels during operation are reduced.

Long service life - Optimized design of the outer surface profile of the rolling element with convexity or logarithmic curve shape can optimize the load distribution between the contact surface of the raceway surface and the rolling element, avoiding the generation of edge stress at both ends of the rolling element. And it can reduce the sensitivity of the bearing to misalignment error and shaft deflection.

Improve bearing reliability - THB tapered roller bearing raceway and rolling body surface profile are optimized and finely machined to ensure a lower surface roughness. It is more conducive to the formation of lubricating oil film when working. Thus improving the overall performance and reliability of the bearing.

Easy to install - Separable and interchangeable bearing parts are more convenient for installation, disassembly and maintenance.

Taper Roller Bearing Advantages

Can bear the combined bearing and radial load

Low friction, low noise, low vibration, longer life

Separable and interchangeable parts for easier installation, disassembly and maintenance

Tapered Roller Bearing VS Ball Bearing

Angular contact ball bearing can withstand a large speed and a certain axial force.

The taper roller bearings bear lower speed than the former, and bear greater axial force than the former.

Tapered Roller Bearing Types

Precision tapered roller bearingsare separable bearings. Both the inner and outer rings of the bearing have tapered raceways. This type of bearing is divided into single row, double row and four row tapered roller bearings according to the number of columns of rolling elements.

Generally, the tapered angle of the outer ring raceway of a single row tapered roller bearing is between 10° and 19°, which can bear the combined action of axial load and radial load at the same time. The greater the cone angle, the greater the ability to withstand axial load. Bearings with large taper angle, add B to the rear code, and the taper angle which is between 25° and 29°can bear larger axial loads. In addition, single row tapered roller bearings can adjust the size of the clearance during the installation process.

The cup (or cone) of a double row tapered roller bearing is a whole unit, integrated. The small end faces of the two cones (or cups) are opposite, with a spacer in the middle. The clearance is adjusted by the thickness of the spacer. The thickness of the spacer can also be used to adjust the preload of the double row tapered roller bearing.

The performance of four row tapered roller bearings is basically the same as that of double row tapered roller bearings, but it bears a greater radial load than double row tapered roller bearings and has a slightly lower limit speed. It is mainly used for heavy machinery.

Tapered Roller Bearing vs Cylindrical Roller Bearing

Tapered roller bearings and cylindrical roller bearings have similar names, and both belong to separable bearings, but they are quite different.

Bearing capacity: When cylindrical roller bearings have no ribs or retaining rings, they can only bear radial force; tapered roller bearings can bear radial force and axial force; but they are generally used in the form of bearings with double row or more rows. Double row cylindrical roller bearings can withstand larger radial forces, but no axial forces. In addition to the radial force, the one with a single retaining ring can also withstand the axial force of one side, and the one with double retaining rings can not only bear the radial force, but also bear the axial force of both sides. Double-row and multi-row tapered roller bearings can withstand radial forces as well as axial forces on both sides.

Running speed: The speed of single row cylindrical roller bearings is the best. Whether they are double row cylindrical roller bearings, cylindrical roller bearings with single ribs, or cylindrical roller bearings with retaining rings, their limiting running speeds are faster than tapered roller bearings.

Accuracy: Generally, the accuracy of single-row and double-row cylindrical roller bearings is better than that of single row tapered roller bearings. Compared with other types of bearings, cylindrical roller bearings and tapered roller bearings have lower accuracy.

Noise: Among them, the single row cylindrical roller bearing has the lowest noise.

These differences determine their different working environments. If you want to choose the most suitable bearing, you need to know enough about the characteristics of the bearings.

As one of industrial bearing manufacturers, we have types of industrial bearing for sale, if you have any needs, please leave us a message.

Send product request

Other supplier products

| V Groove Roller Bearing | A china v groove ball bearingis a type of bearing that has a V-shaped groove in its outer ring. The rollers in the bearing are also V-shaped and ru... | |

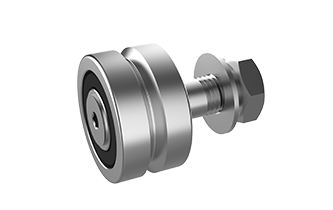

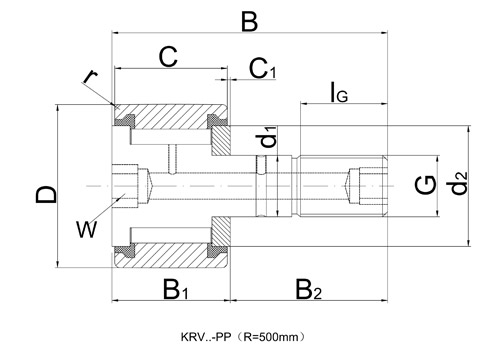

| KRV 52 PP Cam Follower | Specifications of KRV 52 PPCam Follower Designation KRV52PP (Mass)m≈g 463 Dimens... | |

| NKIA 5907 Combined Needle Roller Bearing | Specifications of NKIA 5907Combined Needle Roller Bearing Designations NKIA5907 Dimensions(mm) d 35 D ... | |

| Cam Roller | Cam yoke roller, also called ball bearing track roller. They are non-separable,single-row or double-row ball bearings with thick outer rings. In... | |

| Angular Contact Thrust Ball Bearing | Performance of Angular Contact Thrust Ball Bearing It can accommodate both radial and axial loads with high load capacity, adaption to high speeds... |

Same products

| Tandem roller bearing M4CT3278 with shaft 78x32x110.5mm | Seller: JinHang Precision Bearing Co.,LTD | The tandem roller extruder bearing m4ct3278 that use for PVC screw extruder gearbox, the shaft di... | |

| Tandem roller bearing F-86722 for Rubber extrusion machine | Seller: JinHang Precision Bearing Co.,LTD | The bearing f-51909 t3ar mainly used in the twin screw plastic extrusion machine gearbox.The bear... | |

| Tandem roller bearing t6ar3278 for the extruder shaft gearbox | Seller: JinHang Precision Bearing Co.,LTD | The bearing T6 AR 3278 with size 32X78X163.5mm mainly used for the high speed extruder machine ge... | |

| Tandem roller bearing MTCT2468 for Screw extrude gearbox | Seller: JinHang Precision Bearing Co.,LTD | The bearing M5CT2468 for food/feed/plastic/rubber extrusion machine gearbox use. With high perfor... | |

| twin screw extruder gearbox used t5ar3278 bearing | Seller: JinHang Precision Bearing Co.,LTD | Bearing T5AR3278 fullsize 32x78x137mm bearing actual picture, Please reference them. Bearing fact... |