Automotive Mold

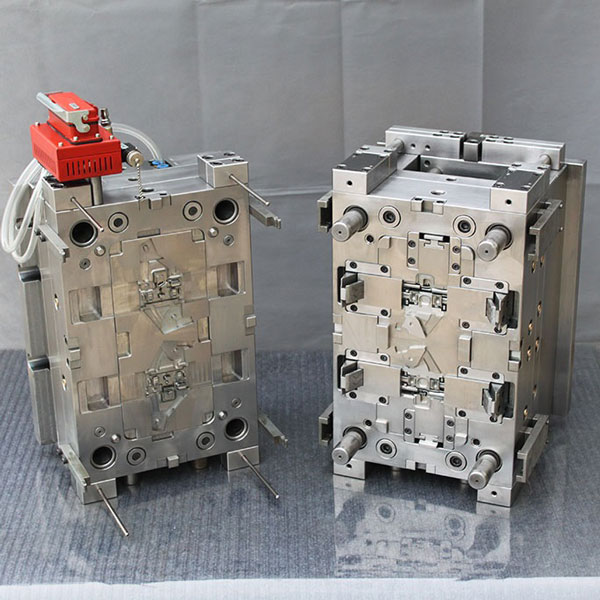

HanKing Mould serves global Automotive & Vehicle products customers, more than 10 years of experience enabling the HanKing team to provide customers the fast development time and stable quality to ensure the new project running well. HanKing engineer will analysis the filling to obtain the best gate position the best flowing regime, and design the best cooling channel to ensure the minimum wrapping deformation and we have a very good injection operator to help set the best injection parameter to avoid any development time waste and improving the molding parameter reliability.

HanKing Mould is very experienced in small and medium-sized precision auto parts molds, in the past years, the types of products we involved were included fuse and fuse box, connector, switch, relay, sensors, actuators, terminal, valve, handle and other body accessories. We are one of the leading automotive moldsmakers in China.

Why are automotive plastic mouldImportant?

In the development of the automotive industry, the proportion of plastic parts in automotive parts is very large, and the demand for plastic parts is increasing day by day because plastics have the advantages of beautiful appearance, lightweight and easy processing. Most plastics have a specific gravity of 0.9 to 1.6, and the proportion of glass fiber reinforced composites will not exceed 2.0, while A3 steel is 7.6, brass is 8.4, and aluminum is 2.7. The use of plastic can reduce the weight of parts by about 40%, and the cost can be greatly reduced, which makes plastic the preferred material for automotive light-weighting. Plastic is easy to molding parts with complex shapes. According to the plastic composition of the plastic, by adding different fillers, plasticizers and hardeners to produce the desired properties of the plastic, changing the mechanical strength and processing properties of the material to meet the requirements of different parts of the car. The plastic consumption of each auto part accounts for 20% of the total vehicle materials and may reach 35% in the future. When the auto company develops a new car, it needs to use hundreds of sets of customized automotive injection mould, which requires the quality assurance of plastic parts in production, and the quality of plastic parts is determined by the mold. Learn more about how to improve the quality of the mold.

Which Parts of the Car Are Commonly Used in Plastic?

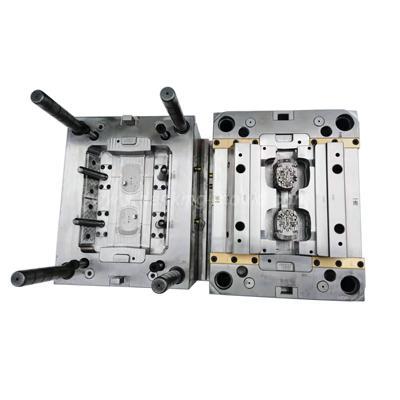

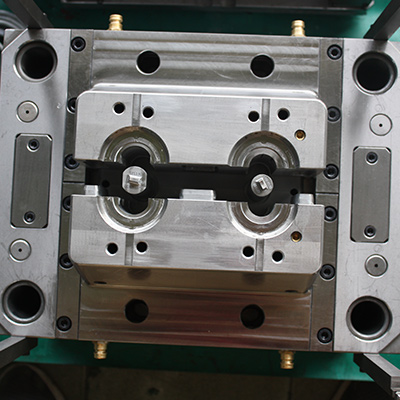

Auto parts mold refers to a specialized tool used in the manufacturing process of automotive parts. It is a precision tool that is used to shape raw materials, typically plastic or metal, into the desired shape and size for use in automobiles.

Auto parts molds are typically made of high-quality steel and are designed to withstand high temperatures and pressure. They are used in injection molding machines, which melt the raw materials and then inject them into the mold to create the finished product.

Bumper, the instrument panel accessories, inlet grille, fender, radiator grille, trim panel, engine parts, Water tank accessories, air conditioning accessories, air filter accessories, various kettles, seat accessories, floor panel accessories, roof panel accessories, bar accessories, steering wheel accessories, door trims, rearview mirrors and various fastener, front and rear lamp, etc.

Send product request

Other supplier products

| Electronic Molding Parts | Two Color Tooth Brush Injection Mould Plastic Parts Make plastic injection moldingand injection molding production for two color tooth brush inject... | |

| Insert Molding | What is medical insert molding? Insert molding toolingrefers to a molding process in which an integrated product is made by inserting a pre-prep... | |

| Insert Molding Technologies for Automotive Industry | Mould Type: Automotive Sensor Plastic Injection Mould Production Material: Nylon PA66 No of Cavities: 4 cavities Core Material: S7 Cavity Mater... | |

| Insert Molding | Plug Mold Mould Name: Plastic Injection Wall Plug Mold Part Material:PBT GF15 Product Size: Product Description: Plug CH versionMould Cavity: 4 Cav... | |

| Family Mould | What is the family mold? A mold that can only produce one product at a time is called a single-cavity injection mold. If a mould is used to prod... |

Same products

| Galvanized Fishtail Terminal End for Highway Guardrail | Seller: Wuhan Dachu Traffic Facilities Co., Ltd | Galvanized Road Fence Highway Guardrail Crash Barrier Terminal Endare the specially designed end ... | |

| COMMUNICATIONS PARTS | Seller: ShenZhen Haohaichang Industrial Co.,Ltd | High Precision Parts are radar system componentsin radar systems, where accuracy, reliability, an... | |

| POM CNC TURNING PARTS | Seller: ShenZhen Haohaichang Industrial Co.,Ltd | CNC POMturning parts are precision components made from polyoxymethylene (POM) using computer num... | |

| Nut | Seller: ShenZhen Haohaichang Industrial Co.,Ltd | Nuts are essential hardware components that work in tandem with bolts, screws, or other threaded ... | |

| HEATINGS/APPLIANCES PARTS | Seller: ShenZhen Haohaichang Industrial Co.,Ltd | High Precision Parts are essential components in heating and appliance systems, contributing to t... |