Automotive Hot Stamping Tool Die

All supplier products

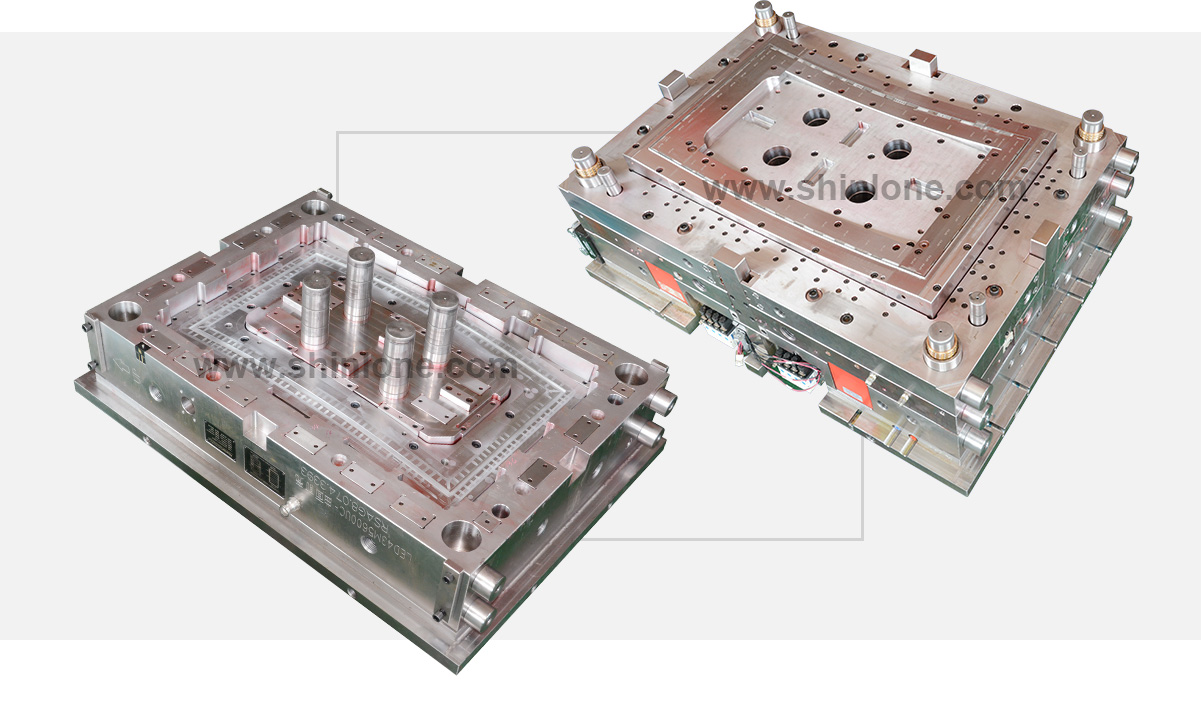

Automotive Hot Stamping Tool Dieis an innovative process by which advanced ultra high strength steel is formed into complex shapes more efficiently than with traditional cold stamping.

The process involves the heating of the steel blanks until they are malleable, followed by formation and then rapid cooling in specially designed hot forming die, creating in the process a transformed and hardened material.

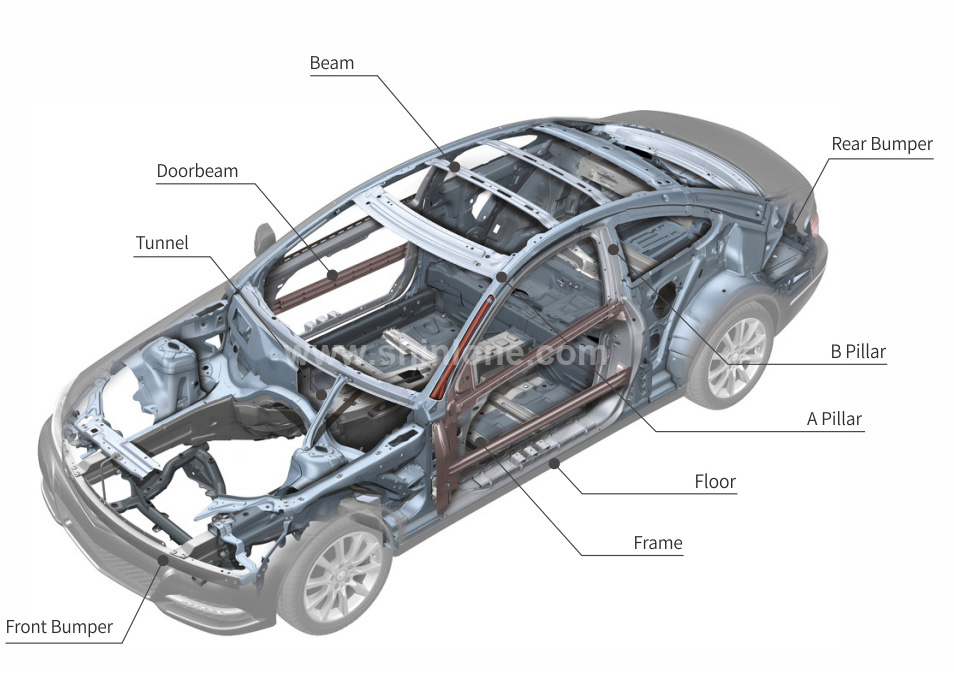

Because of this ability to efficiently combine strength and complexity, press hardened parts accomplish in one relatively light-weight piece what would typically require thicker, heavier parts welded together in more than one process under cold stamping.

Press hardening parts therefore currently represent one of the most advanced lightweight solutions for the car body structure that simultaneously allows us to improve crash performance and passenger safety requirements.

We are the supplier of press hardening tools, hot stamping dies, hot stamping tools, hot stamping automotive parts,auto hot stamping tools,hot forming tool, hot forming die. Our press hardening production model cover the entire value chain from the manufacturing of our own dies to production lines in the future.

We are Dies & Hot Forming Die, hot stamping toolingsupplier,provide hot forming tool and hot stamping tools.

Send product request

Other supplier products

| TV mould supplier | The TV Mould include: Front Cover, Bottom Cover, and TV Frame We have a great experience of making TV mould, the front frame we use RHCM (Ra... | |

| tv frame mould | We have a great experience of making TV mould, the front frame we use RHCM (Rapid Heat Cycle Molding) technology, Our main customer include Hisense... | |

| Rapid Heat Cycle Molding | The TV Mould include: Front Cover, Bottom Cover, and TV Frame We have a great experience of making TV mould, the front frame we use RHCM (Ra... | |

| rhcm molding | The TV Mould include: Front Cover, Bottom Cover, and TV Frame We have a great experience of making TV mould, the front frame we use RHCM (Rapid H... | |

| 2k mold process | 2K injection mold, two kinds of plastic material in the same injection machine, two times of forming, but the product out of the mold only once. T... |

Same products

| Motorcycle Body and Frame Plastic Mold | Seller: Taizhou Huangyan Jingnan Moulding Co., Ltd. | As a key component mold professionally manufactured by Jingnan Mould, motorcycle body frame plast... | |

| For 2017 Audi A7 Rear Bumper Mould | Seller: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Mould Name Audi A7 Car Bumper Mould Material PP+EPDM(Contraction: 1, 5%) Bumper Size 1800*510*460... | |

| For Mercedes-Benz-C-206 Modified Bumper Mould | Seller: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Taizhou Huangyan Chenpeng Mold Co., Ltd. is a professionalwholesale Mercedes-Benz-C-206 Modified ... | |

| Front Bumper Lower Lip Mould For 2021 Honda CRV | Seller: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Introducing the for 2021 Honda CRV Front Bumper Lower Lip Mould: Elevate Your Driving Experienc... | |

| Bottle cap mold | Seller: Taizhou Huangyan Yongsheng Mould Co., Ltd. | Taizhou Yongsheng Mould Co., Ltd. can produce cap moulds ()within 64 cavities. The hot runner or ... |