BMC/SMC Products

BMC/SMC Products Description:

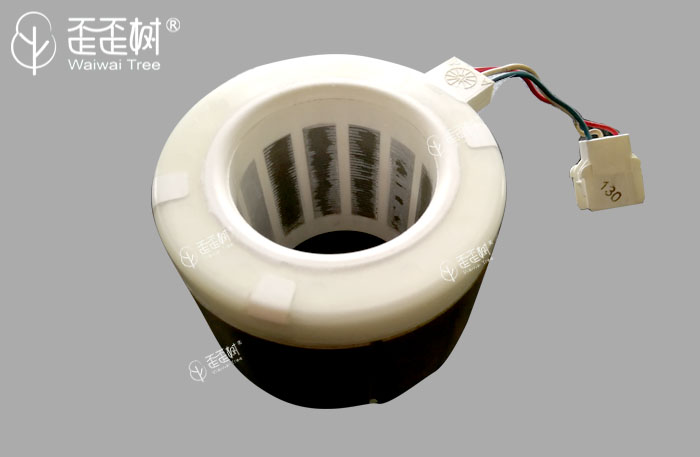

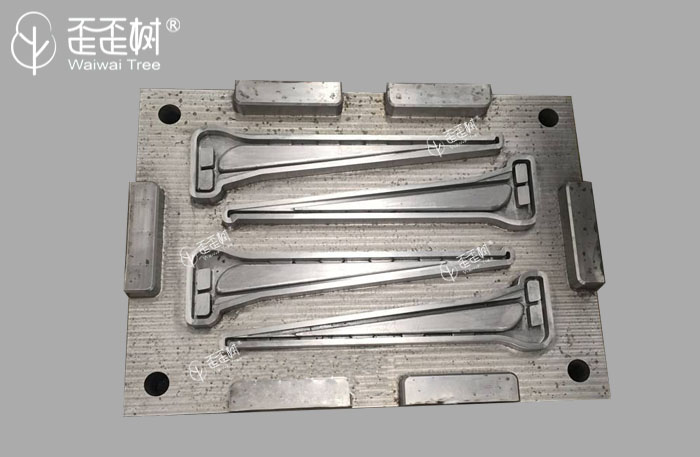

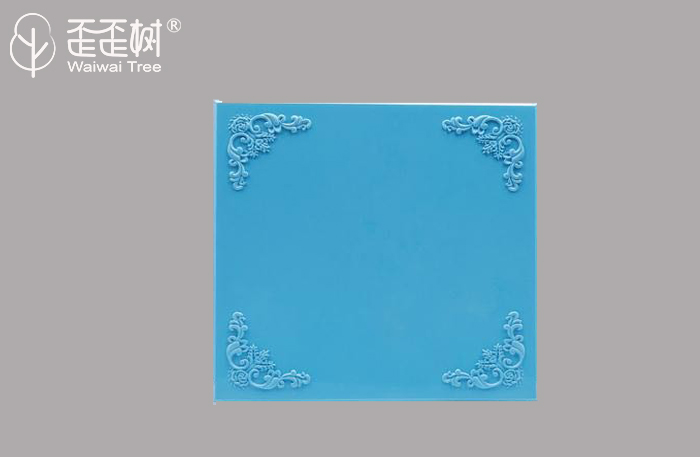

SMC, BMC thermosetting plastic products(such as )are produced by SMC and BMC plastic molding process. SMC/BMC is one of thermosetting plastics, and SMC/BMC thermosetting plastics are thermosetting molding compounds made of unsaturated polyester resin as matrix resin. The main components of SMC/BMC thermosetting plastics include resins, thickeners, low shrinkage additives, fillers, internal mold release agents, colorants, stabilizers, and the like. It is first formulated into a resin paste and then used to impregnate or blend with a reinforcing material to form a preformed molding material. According to the preforming process and the shape of the obtained preformed material, it can be divided into SMC thermosetting plastic and BMC thermosetting plastic or DMC integral molding plastic. SMC/BMC thermosetting plastics are easy to form, have low molding shrinkage, high dimensional accuracy and good processing performance. SMC/BMC thermoset plastic products have excellent electrical insulation, heat resistance, flame retardancy and good mechanical strength. SMC, BMC thermosetting plastic products are widely used in electrical, construction, civil appliances, daily necessities and other industries to process a variety of insulation, structural parts, decorative parts and daily necessities.

BMC/SMC Products Features:

High insulation, chemical resistance, high fire resistance, good water resistance, accurate size, stable working performance, light weight, high strength, acid and alkali resistance, waterproof and moisture proof.

We have complete processing and testing capabilities as well as ISO14001:2004 and ISO9001-2008 management system. With our fast delivery, perfect after-sale service and stable quality, Zhejiang Aobang series plastic-sealed DC motor molds and products can be your best choice for your concern.

Send product request

Other supplier products

| SMC Cable Braket Moulding | Mainly for pressure molding, the cavity pressure should be considered as small as possible when designing the parting surface. The exhaust should b... | |

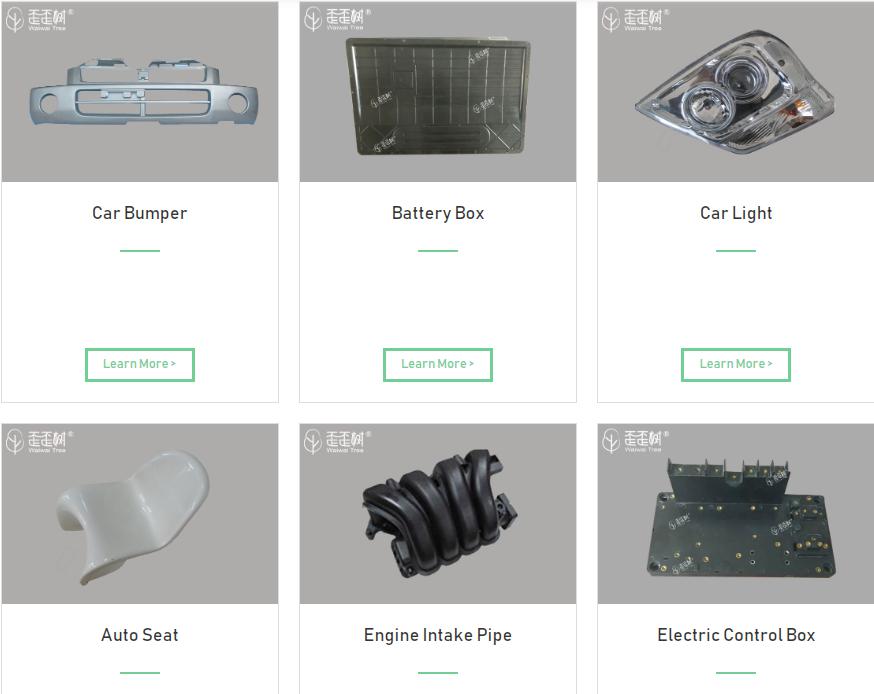

| Auto Parts And Accessories | Auto Parts Description Parts made from sheet molding compound (SMC) are typically 25-35% lighter than steel parts and aluminum products of the same... | |

| BMC, SMC, GRP, GFK Roof Tiles | The BMCcompositeprecision molds produced by Waiwai Tree have the characteristics of low energy consumption; our SMC and BMC moldinghave no waste, a... | |

| Shell Moulding | Shell MouldingDescription Mainly for injection molding, the cavity pressure should be considered as small as possible when designing the runner an... | |

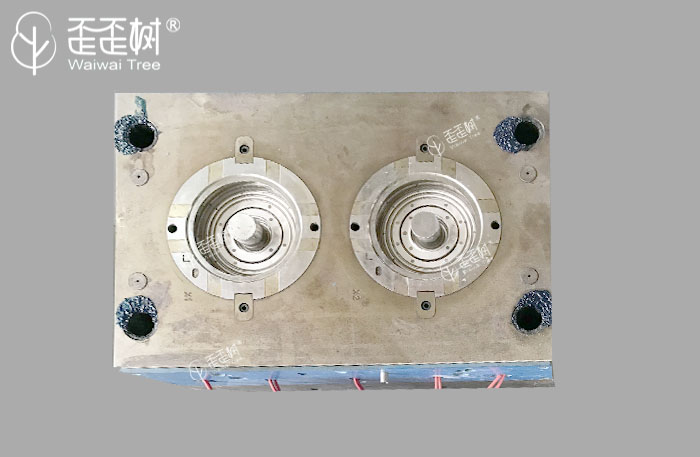

| BMC/SMC Molds | Custom high Precision Compression/Injection Moulds Manufacturing with fast lead time BMC/SMC Mould Manufacturer As one of sheet molding compoun... |

Same products

| Motorcycle Body and Frame Plastic Mold | Seller: Taizhou Huangyan Jingnan Moulding Co., Ltd. | As a key component mold professionally manufactured by Jingnan Mould, motorcycle body frame plast... | |

| For 2017 Audi A7 Rear Bumper Mould | Seller: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Mould Name Audi A7 Car Bumper Mould Material PP+EPDM(Contraction: 1, 5%) Bumper Size 1800*510*460... | |

| For Mercedes-Benz-C-206 Modified Bumper Mould | Seller: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Taizhou Huangyan Chenpeng Mold Co., Ltd. is a professionalwholesale Mercedes-Benz-C-206 Modified ... | |

| Front Bumper Lower Lip Mould For 2021 Honda CRV | Seller: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Introducing the for 2021 Honda CRV Front Bumper Lower Lip Mould: Elevate Your Driving Experienc... | |

| Bottle cap mold | Seller: Taizhou Huangyan Yongsheng Mould Co., Ltd. | Taizhou Yongsheng Mould Co., Ltd. can produce cap moulds ()within 64 cavities. The hot runner or ... |