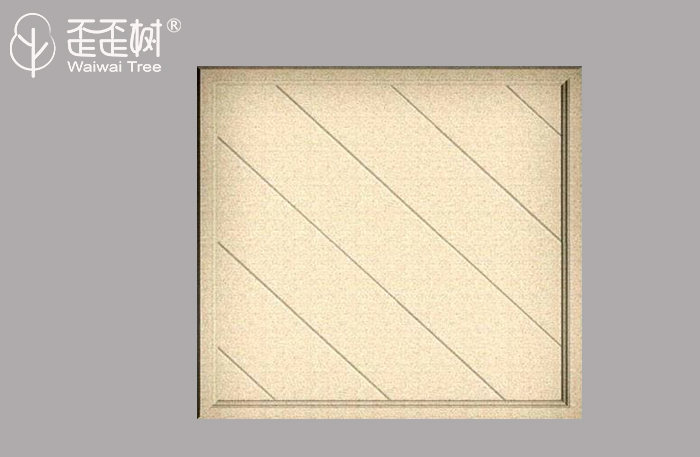

BMC, SMC, GRP, GFK Ceiling

The BMCcompositeprecision molds produced by Waiwai Tree have the characteristics of low energy consumption; our SMC and BMC moldinghave no waste, and there is no need to clear the inner cavity. Having only a small temperature difference, our SMC/BMC composites have stable mold temperature, good appearance, and high efficiency.

Ceiling is a kind of decoration on the top of living environment. In short, it refers to the ceiling decoration, is an important part of interior decoration. The ceiling has the functions of heat preservation, heat insulation, sound insulation and sound absorption. It is also the hidden layer of electrical, ventilation, air conditioning, communication fire prevention, alarm pipeline equipment and other projects.

Aobang composite ceiling is divided into: BMC ceiling, SMC ceiling, GRP ceiling, GFK Ceiling.

Development of ceiling molding material

lThe ceiling materials have been developed for more than ten years, and the technology is constantly being updated. The PVC ceiling is not resistant to high temperature, and it is easy to deform in a hot environment. The plastic steel plate is improved from the second generation of ceiling material PVC, which has the advantages of lower price, good thermal insulation and sound insulation, rich color and easy making and installation.

lHowever, according to the supervision and inspection results of the plastic sheet market by the Supervisory Office, the quality pass rate of plastic steel products on the market is only 40%, and the phenomenon of “water injection” in bending strength, coating thickness and alkali resistance is serious. Moreover, the plastic steel sheet has low strength, is easily twisted, is not environmentally friendly, has poor weather resistance, and releases toxic gases when burned. The physical properties of the composite material aggregate ceiling are very stable, and will not be deformed even if the water is long time.

lThe composite ceiling is an excellent material for the ceiling and naturalization board in terms of strength and rigidity. The ceiling uses BMC,SMC,GRP,GFK bulk molding compound as a completely environmentally friendly material.

BMC,SMC,GRP,GFK composite material ceiling advantages

lBeautiful, moisture-proof, easy to clean, excellent flame retardant effect, high strength, long life, high environmental protection, easy installation, moisture-proof and waterproof, heat insulation, corrosion resistance, tight connection, oxidation resistance, anti-aging, no deformation, high strength, Light and tough, with natural texture and wooden texture, a variety of colors, natural and beautiful, with a variety of specifications, size, shape, thickness, the same processing properties as logs, no pollution, recycling, no cracks, no expansion, no deformation, no maintenance, no mold, anti-corrosion, anti-insect, anti-termite, energy saving. What is important is the low material cost of BMC,SMC,GRP,GFK molding compound, making it a cost-effective ceiling material than such as steel-plastic panels, aluminum gussets, and aluminum alloys.

lThe visual effect is soft, feels good, high strength, flame retardant, fireproof, and has strong weather resistance.

lExcellent insulation and heat insulation performance, which overcomes the poor thermal insulation performance of traditional ceilings.

lGood water resistance, no corrosion, no deformation, no fading and no other undesirable phenomena in a humid environment.

lExcellent sound absorption, it is a good sound insulation material, suitable for public places such as medium and high-grade office buildings and large conference halls.

Lifetime usage of the BMC, GFK, GRP, SMC Ceiling

A competitive good point of the BMC, GFK, GRP, SMC Ceiling is that you can use it for 25 to 30 years without any sign of breaking or deterioration. Researches show that, a BMC, GFK, GRP, SMC Ceiling’s estimated lifetime is 28 years. The BMC, GFK, GRP, SMC Ceiling has no obvious weak point, and since it is fire-proof and chemical-proof, it would not easily damaged by man.

BMC, GFK, GRP, SMC Ceiling is the environmentally friendly choice

Compared with other ceiling materials, one important aspect of BMC, GFK, GRP, SMC Ceiling is that it’s environmentally friendly. It need less energy than other materials, and since it’s “cold-applied”, there is no need to use heat sources for installation.

BMC, GFK, GRP, SMC Ceiling is here! Offered by Aobang!

Aobang is a professional manufacturer offer molding for ceiling and wall panels, especially GRP tiles, GFK plastic, SMC ceiling fan parts, GRP battery box, gfk panel, and other BMC, GFK, GRP, SMC material parts. Please contact us to check more plastic ceiling molding services and the attractive price.

Send product request

Other supplier products

| SMC Cable Braket | The SMC cablebracket is a combination consisting of a cable bracket, a post and a fixed pin. The material of the column and the pin is also made by... | |

| BMC/SMC Motor | BMC/SMC Motor Description BMC plastic edging motor replaces traditional iron and aluminum, reduces the process, seals more, and has higher safet... | |

| BMC, SMC, GRP, GFK Wall Panel | Composite wall panel is a new generation of high performance building partition board made of a variety of building materials instead of traditiona... | |

| BMC, SMC, GRP, GFK Ceiling | Aobang composite ceiling is divided into: BMC ceiling, SMC ceiling, GRP ceiling, . The ceiling materials have been developed for more than ten yea... | |

| SMC Cable Braket | The SMC cable bracket is a combination consisting of a cable bracket, a post and a fixed pin. The material of the column and the pin is also made b... |

Same products

| Motorcycle Body and Frame Plastic Mold | Seller: Taizhou Huangyan Jingnan Moulding Co., Ltd. | As a key component mold professionally manufactured by Jingnan Mould, motorcycle body frame plast... | |

| For 2017 Audi A7 Rear Bumper Mould | Seller: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Mould Name Audi A7 Car Bumper Mould Material PP+EPDM(Contraction: 1, 5%) Bumper Size 1800*510*460... | |

| For Mercedes-Benz-C-206 Modified Bumper Mould | Seller: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Taizhou Huangyan Chenpeng Mold Co., Ltd. is a professionalwholesale Mercedes-Benz-C-206 Modified ... | |

| Front Bumper Lower Lip Mould For 2021 Honda CRV | Seller: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Introducing the for 2021 Honda CRV Front Bumper Lower Lip Mould: Elevate Your Driving Experienc... | |

| Bottle cap mold | Seller: Taizhou Huangyan Yongsheng Mould Co., Ltd. | Taizhou Yongsheng Mould Co., Ltd. can produce cap moulds ()within 64 cavities. The hot runner or ... |