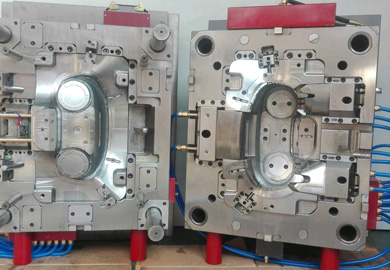

Multi Cavity Mould

A multi cavity moldis known as a mould with multiple cavities. The multi-cavity mold consists of a multi-cavity of different plastic parts.

Though multi-cavity plastic injection moldingprocess may be much more complex than others such as insert injection molding process, it is still popular as the improvements of production efficiency and cost-efficiency. As a leading multi-cavity mould manufacturer, GM-TECH provides you with high-grade multiple cavity mould to meet the needs of high-yield, high-precision products.

Features of Multi Cavity Mould

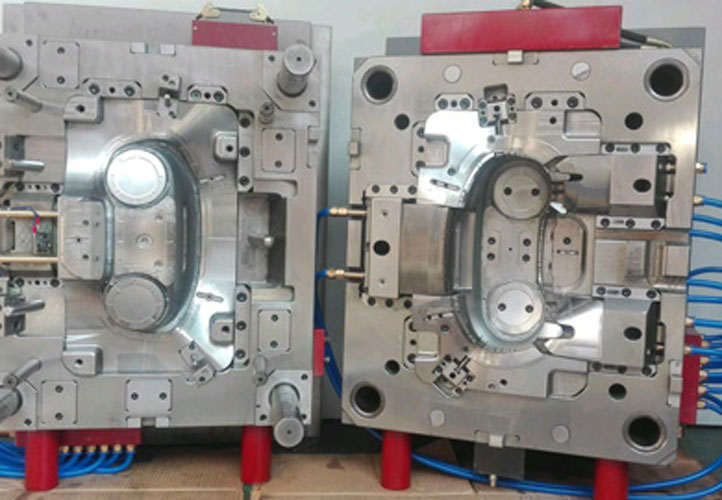

Multi cavity molds contain more than one cavity of the same part. It’s able to produce many parts per custom plastic injection moldingcycle with high-volume production. Here are some major features of a multi-cavity mould.

More parts can be manufactured by the same mold within the cavity.

Generally speaking, a multi-cavity mould is at a lower custom plastic molding cost than a single cavity mould.

The requested number of components will be finished faster due to the shorter lead time per batch.

More efficient use of the cycle time

The processes of multi-cavity mould are more stable

It keeps flow balance of cavity injection molding

The Specification of Multi Cavity Mould

|

Part material |

PP |

|

Cavity |

16 |

|

Runner:16 drops hot runner |

|

|

Mold accuracy |

+ / - 0.02 |

|

Mold steel |

|

|

Mold blank steel |

|

|

Mold life |

100W |

|

Mold standard |

HASCO |

|

Mold structure |

12 lifters |

|

Exporting country |

Australia |

|

Lead time |

5 weeks |

|

Mold quality customer satisfaction |

1 |

|

FAI pass rate |

1 |

|

Project cooperation service customer satisfaction |

1 |

How does Multi Cavity Mould Work?

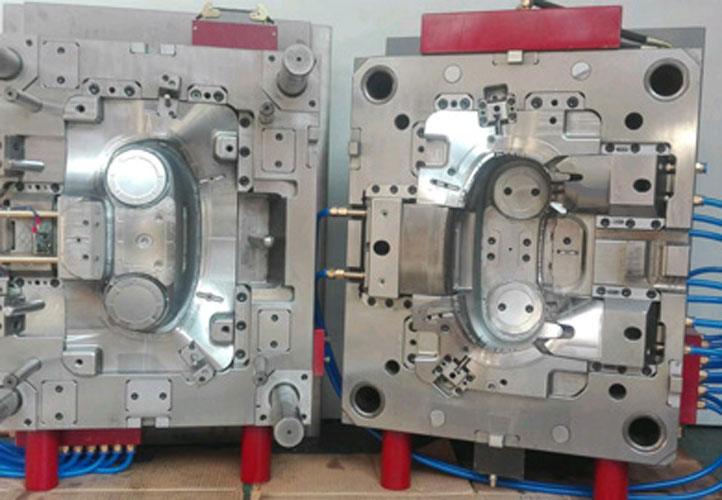

The basic manufacturing process of multi-cavity mould by GM-TECH, a professional company specializing in moulding products, are as follows:

Plastic is melted in a plastic injection molding machine and then injected into a mold under high pressure. The material is cooled and solidified inside the mold, then the two halves are opened and the product is removed. The technology produces plastic products with predetermined fixed shapes.

To simplify production, the parts of multi-cavity mould that function in the plastic injection molding process must be carefully designed. Products made using multi-cavity injection molding machines are first designed by industrial engineers or designers. The die manufacturer takes into account all the key conditions: the materials used in the final product, the function of the product; In addition, the material of the mold, and the characteristics of the multi-cavity injection molding machine.

Send product request

Other supplier products

| CNC Components | CNC Components Gmmoldtech CNC component can greatly reduces the number of tooling, and complex tooling is not needed to process complex parts. ... | |

| Die Casting Mould | GM-TECH, plastic injection molding manufacturer,has been manufacturing tools for injection molding of plastics for various industries for more than... | |

| Die Casting | GM-TECH, injection molding supplier,has been manufacturing tools for injection molding of plastics for various industries for more than 10 years. W... | |

| Electronics Product Mould | Decades of accumulation of mould manufacturing technology have witnessed the popularity of electrical plastic molding products. The electronics ... | |

| Mould Design | GM-TECH have a much experienced design team, familiar with China domestic, European, American, Japanese and other mold design standards, be able to... |

Same products

| Motorcycle Body and Frame Plastic Mold | Seller: Taizhou Huangyan Jingnan Moulding Co., Ltd. | As a key component mold professionally manufactured by Jingnan Mould, motorcycle body frame plast... | |

| For 2017 Audi A7 Rear Bumper Mould | Seller: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Mould Name Audi A7 Car Bumper Mould Material PP+EPDM(Contraction: 1, 5%) Bumper Size 1800*510*460... | |

| For Mercedes-Benz-C-206 Modified Bumper Mould | Seller: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Taizhou Huangyan Chenpeng Mold Co., Ltd. is a professionalwholesale Mercedes-Benz-C-206 Modified ... | |

| Front Bumper Lower Lip Mould For 2021 Honda CRV | Seller: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Introducing the for 2021 Honda CRV Front Bumper Lower Lip Mould: Elevate Your Driving Experienc... | |

| Bottle cap mold | Seller: Taizhou Huangyan Yongsheng Mould Co., Ltd. | Taizhou Yongsheng Mould Co., Ltd. can produce cap moulds ()within 64 cavities. The hot runner or ... |