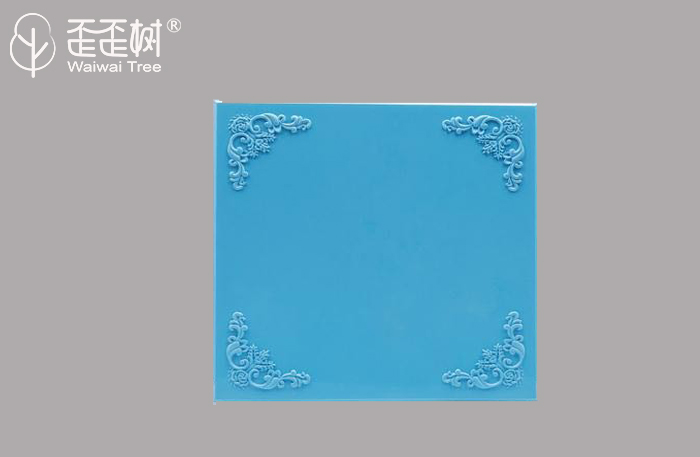

BMC, SMC, GRP, GFK Building & Decoration Materials

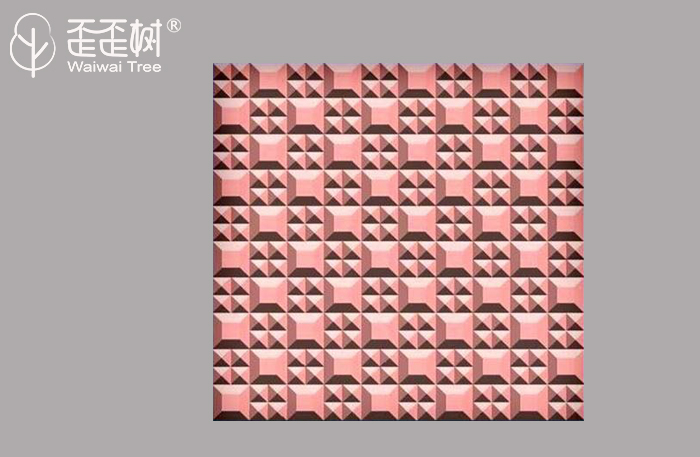

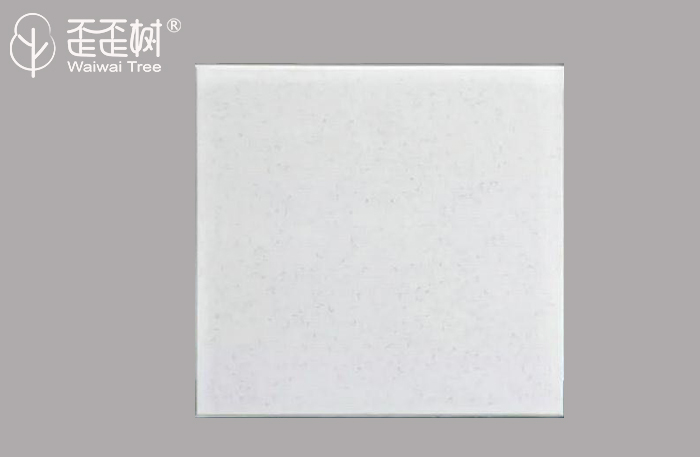

Building decoration materials, also known as building finishing materials, refer to the materials laid or painted on the surface of buildings to decorate and beautify the environment. Building decoration materials are the important material basis of building decoration engineering. The overall effect of architectural decoration and the realization of architectural decoration function are restricted by architectural decoration materials to a certain extent, especially by the decorative characteristics of decorative materials, such as luster, texture, and pattern.

Aobang composite Building & Decoration materialis divided into: BMCcompositebuilding decoration material, SMC building decoration material, GRP building decoration material, GFK building decoration material.

Building decoration materials functions

Beautify urban and rural buildings, improve people's living environment and working environment.

Change the layout of the room to meet the use function of the room.

Laid on the surface of the building, in order to beautify the building and the environment, regulate people's mind, and play the role of protecting the building. Modern architecture requires that the architectural decoration should follow the aesthetic principles, create a good space environment with the meaning of improving life, balance people's body and mind, regulate their emotions, and give better play to their wisdom.

GFK, SMC, GRP, and BMC building materials advantages

Building decoration materials may have heard of commonly used materials such as sandstone and cement. BMC, SMC, GRP, and GFK composite materials have been heard by few people. It is a new type of material. What are the advantages?

Short molding cycle, can be molded or injected, suitable for mass production.

A large amount of filler can be added to meet the requirements of flame retardancy and dimensional stability, and the cost is low.

Complex products can be integrally formed, and inserts, holes, tables, ribs, grooves, etc. can be molded at the same time.

Compared with ordinary thermoplastics, the heat resistance, insulation and modulus of elasticity of the products are higher.

The skills of workers are not high, and it is easy to automate and save labor.

The size of the product is accurate.

The working environment is good.

Here are the long lifetime building decoration materials

According to researches, fiberglass roof tiles have a long lifetime more than most other materials. GFK, SMC, GRP, and BMC materialscan last for 25-50 years in any natural environment, while the traditional materials normally can only last for 10-15 years. This is one of the reasons why GFK, SMC, GRP, and BMC materials are of high performance/cost ratio, and why this kind of material become increasly popular in various areas.

Here are the environmental friendly building decoration materials

The application of GFK, SMC, GRP, and BMC building materials can effectively reduce indoor environmental pollution, reduce the harm of pollutants emitted by decoration materials to human body, and environmental protection materials can be recycled. This recycling of building decoration materials can reduce pollution and save resources.

Find the great building decoration materials here in Aobang!

Aobang has affluent experience in GFK, SMC, GRP, and BMC building materials, you can find various types of building material here, such as resin roof tiles, SMC tiles, BMC tiles, GRP building products, etc. To check more products of GRP material, SMC material, or other fiberglass related new material, please contact us now!

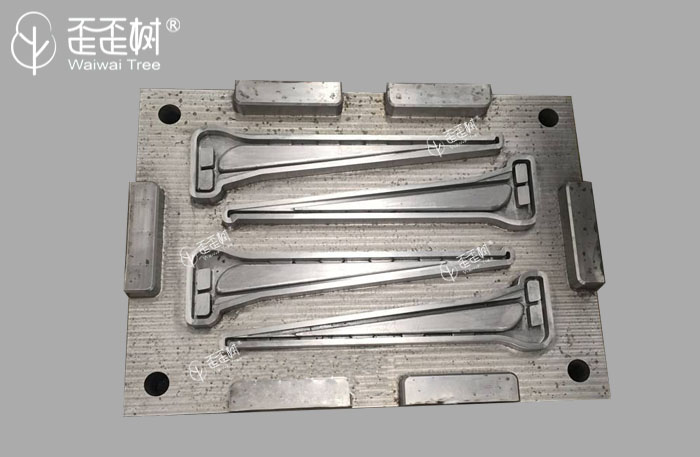

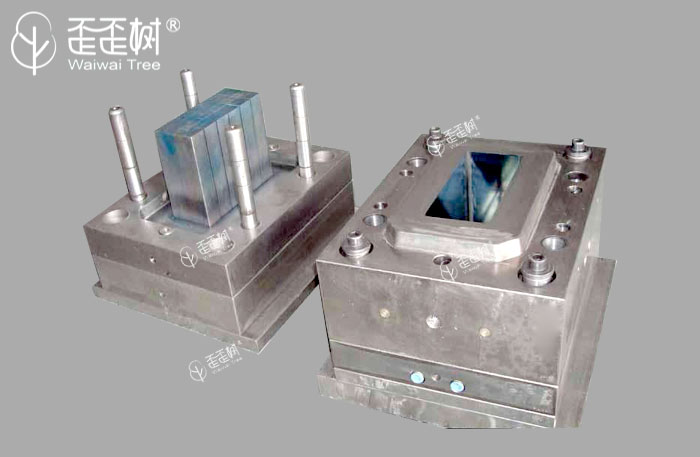

BMCmoldingcustom molds and products manufacturing with bulk molding compound and sheet molding compound, which is superior to meet specific needs in compression moulding and injection moulding.

Send product request

Other supplier products

| SMC Cable Braket Moulding | Mainly for pressure molding, the cavity pressure should be considered as small as possible when designing the parting surface. The exhaust should b... | |

| Auto Parts Mould | BMC Car PartsMould Automobiles are different in size and shape. That means automobile suppliers always need flexible auto parts molds, once there ... | |

| BMC, SMC, GRP, GFK Ceiling | Aobang composite ceiling is divided into: BMC ceiling, SMC ceiling, GRP ceiling, GFK Ceiling. The ceiling materials have been developed for more t... | |

| BMC, SMC, GRP, GFK Building & Decoration Materials | Building decoration materials, also known as building finishing materials, refer to the materials laid or painted on the surface of buildings to de... | |

| BMC, SMC, GRP, GFK Roof Tiles | BMC, SMC, GFK, GRPRoof Tiles BMC, SMC, GFK, GRP roofing materialsare glassfiber reinforced plastic, also known as glassfiber roof, which are compo... |

Same products

| Motorcycle Body and Frame Plastic Mold | Seller: Taizhou Huangyan Jingnan Moulding Co., Ltd. | As a key component mold professionally manufactured by Jingnan Mould, motorcycle body frame plast... | |

| For 2017 Audi A7 Rear Bumper Mould | Seller: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Mould Name Audi A7 Car Bumper Mould Material PP+EPDM(Contraction: 1, 5%) Bumper Size 1800*510*460... | |

| For Mercedes-Benz-C-206 Modified Bumper Mould | Seller: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Taizhou Huangyan Chenpeng Mold Co., Ltd. is a professionalwholesale Mercedes-Benz-C-206 Modified ... | |

| Front Bumper Lower Lip Mould For 2021 Honda CRV | Seller: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Introducing the for 2021 Honda CRV Front Bumper Lower Lip Mould: Elevate Your Driving Experienc... | |

| Bottle cap mold | Seller: Taizhou Huangyan Yongsheng Mould Co., Ltd. | Taizhou Yongsheng Mould Co., Ltd. can produce cap moulds ()within 64 cavities. The hot runner or ... |