Injection Mold Design Engineering

Injection mold design engineeringis a procedure at the first stage of injection molding process, which develops the injection mold designs to improve the effectiveness and efficiency in injection molding. Plastic mold designtechnical team of R&D and engineers of Keyplast is diligent for every project from our clients. As one ofleadingplastic injection molding manufacturers china, Keyplast could assist our clients to make 2D/3D designs per the samples or concepts and bring their ideas into reality. If any defects, our team will offer professional suggestions and take rapid modifications for every project.

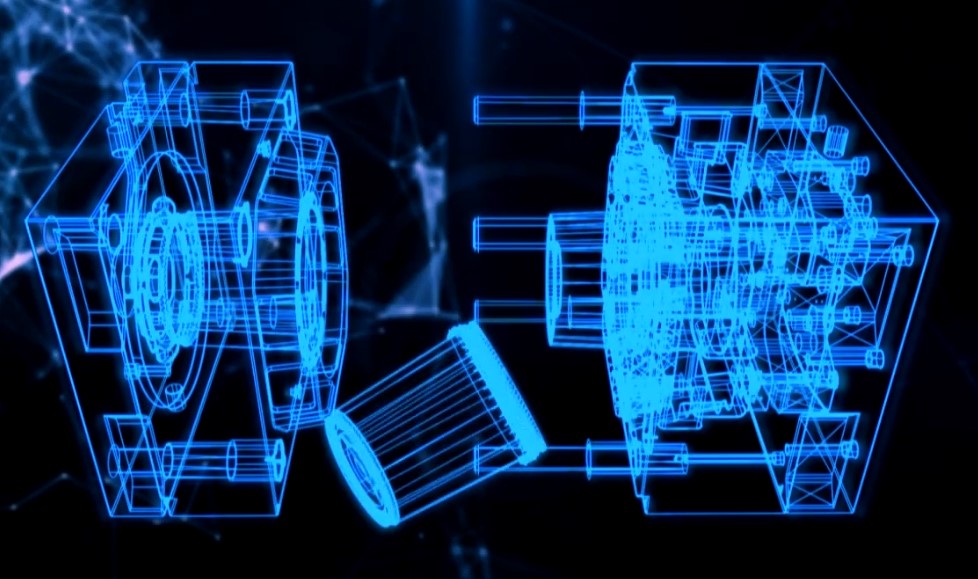

Mold Design

Plastic injection molding mold designis a procedure after confirmation of product design and before molding process. In the mold industry, there's never a one-size fits for all project. For each project whether you send us a sample or a 2D file, we always work with you to make improvements for all technical drawings including 2D files, 3D files of the product. You can start from sharing important details about your project, then our designers will run an analysis on your plastic mold tooling design and make adjustments for injection molding accordingly. With correct injection molding part designs, parts can be manufactured with well consistency and high quality, but without good injection moldingmold designs, you may make costly processing mistakes.

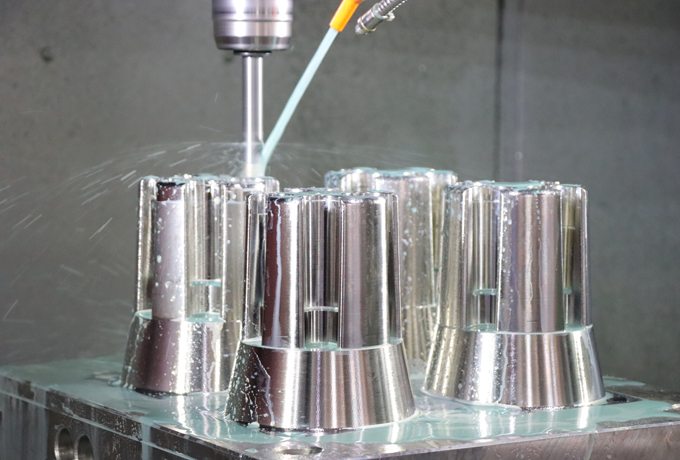

Mold-Flow Analysis

Mold flow Analysis simulates the flow of plastic materials to improve the products and plastic mould design, so to create products of high quality. Mould flow analysis could help you to have a virtual look into how the plastic materials fill the cavities of the molds. It could help to analyze the moulding process before cutting the steel, thus saving money and time.

Prototyping: 3D Printing

3D Printing is a process to produce a 3-dimensional part by using a CAD file. The objects are created layer by layer using a variety of different plastic molding materials and layer bonding techniques, with the types of FDM, SLS, SLA, PolyJet and etc. Compared to CNC process, 3d printed injection moldcould easily achieve a higher level of complexity through rapid prototyping, but 3d injection molding requires less tooling cost at lower volumes, like Multi Jet Fusion. But regarding the manufacturability, wall thickness is a key consideration to ensure parts in sound structure.

Send product request

Other supplier products

| Insert Molding | Insert molding is one category of injection molding that allows preformed parts or components, usually metal inserts, to be inserted into the plast... | |

| Medical Injection Molding | Keyplast has efficient team with many years' experience of injection moulding, while medical industry is one of our mainly focused industries. With... | |

| Plastic Injection Mould Tooling | Plastic Injection Mould Tooling Plastic molds are tools that are matched with plastic mold makers in the plastic processing industry to give plast... | |

| Over Molding | Over moldingof keyplast is a special plastic molding process. Overmolding custom injection moldingis similar to the two-color molding or two-shot m... | |

| Market Status Of China's Mold Manufacturing Industry | In recent years, due to the continuous improvement of China's industrialization, China has become a major mold manufacturing country and a major mo... |

Same products

| Motorcycle Body and Frame Plastic Mold | Seller: Taizhou Huangyan Jingnan Moulding Co., Ltd. | As a key component mold professionally manufactured by Jingnan Mould, motorcycle body frame plast... | |

| For 2017 Audi A7 Rear Bumper Mould | Seller: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Mould Name Audi A7 Car Bumper Mould Material PP+EPDM(Contraction: 1, 5%) Bumper Size 1800*510*460... | |

| For Mercedes-Benz-C-206 Modified Bumper Mould | Seller: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Taizhou Huangyan Chenpeng Mold Co., Ltd. is a professionalwholesale Mercedes-Benz-C-206 Modified ... | |

| Front Bumper Lower Lip Mould For 2021 Honda CRV | Seller: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Introducing the for 2021 Honda CRV Front Bumper Lower Lip Mould: Elevate Your Driving Experienc... | |

| Bottle cap mold | Seller: Taizhou Huangyan Yongsheng Mould Co., Ltd. | Taizhou Yongsheng Mould Co., Ltd. can produce cap moulds ()within 64 cavities. The hot runner or ... |