2K Injection Molding

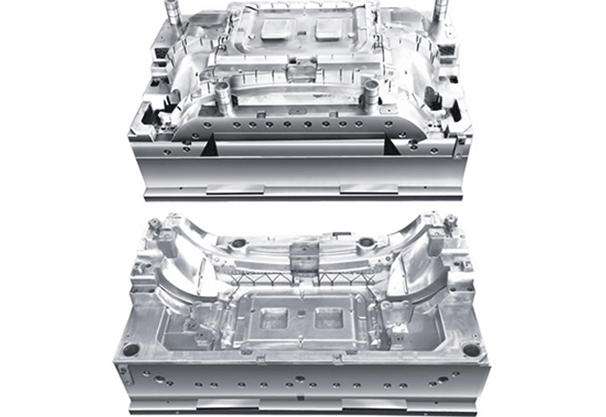

Multi-component molding is a highly efficient and cost-effective technology that enables the molding of custom plastic parts using two or three plastic resins or colors in a single operation, resulting in faster cycle times and flash-free products. As a leading expert in this technology, Packson has mastered the process and has been manufacturing parts using multi-component molding for many years.

With our state-of-the-art 2k injection servicesand advanced 2K technology, we are capable of manufacturing various types of 2K molds. As your competent partner in this area, Packson is committed to providing you with the highest quality products and services. We would be glad to support you in any way we can.

2k injection molding is one type of injection mold. 2k molding is also named as two shot molding, double shot molding, double-color mold, Multi-material, or multi-component injection mold. 2k injection molding consists of two different plastic materials and colors.

What is 2k mould?

2K injection molding, also named a double injection, two-color injection molding, or 2 shot molding, is a process used to produce molded parts from two different materials with two colors.

AAs the 2k moulding factories, we operate 2K injection molding at one machine and perform two injections in one cycle. For the first cycle, plastic material is injected into a mold. Then rotated automatically and mix another property of plastic which was injected into the mold by the second nozzle.

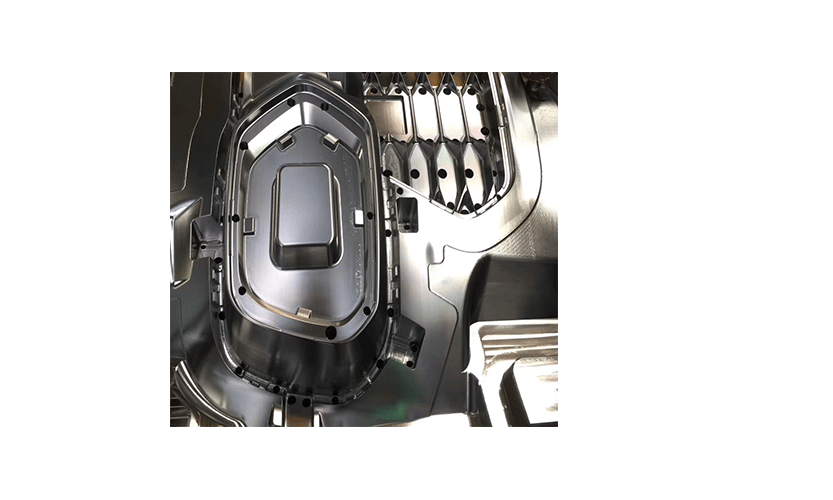

22k plastic injection mouldingintegrates two different grad materials like hard and soft material to make a perfect combination with production. Two color injection molding is widely used in a variety of industries and it also allows for using clear plastics, colored patterns, and new style designs which help to make functionality products like medical plastic parts and reach marketplace value.

2K Mold Design

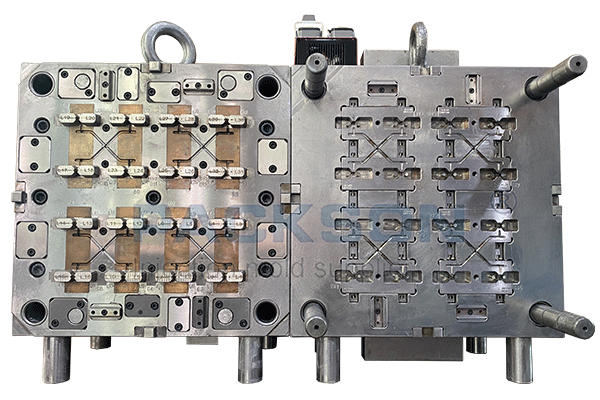

2K molddesign is a pivotal factor for molding success. Followings are factors that will make an influence 2k molding: dimensioning and location of the sprue gates, dimensioning of shear edges, flow aids, cooling and ejector techniques, etc. Here at Packson 2k moulding factories, we keep making good 2K mold designs and we are committed to making durable mold that is highly efficient operating and easy to make maintenance and molding production.

The followings are the points that we need to consider during 2K mold design:

Shrinkage of plastic material

Wall thickness

Cavity Numbers

Plastic material flow systems-Runner and Gate

Cooling system for around cavity and core

Ejection System

Air venting

Applications of 2K Injection Moulding

2K injection molding is perfect for combinations of hard and soft plastics and also if you want to process 2 colors of plastic in one product.

2K injection molding is a good way for you if you want to combine two different materials like hard material and soft material into one product by injection molding processing. We create full products in 2 steps by two color injection molding. The most common example made by 2K injection molding is bicycle handlebar, automotive button, toothbrushes with hard handle and soft handle piece, medical diagnosis machine control button, etc.

2K Molding Design Guide

The 2K injection molding allows us to integrate multiple properties into one product: for instance, layered products, combinations of hard and soft plastic for making different color combinations.

The 2K injection molding allows us to combine two different properties of the material with hard and soft plastic for making two different colors. 2k injection moulding has wide applications and many strengthes.

Here are some advantages Of 2K Injection Molding:

One-stop finished part without secondary processing and assembly steps

Excellent adhesion to the plastic part

Quick cycle times

The high degree of automation

High efficiency

Stable molding processes

Low-cost molding

If you need any kinds of medical injection moulding, please contact us, as a professional china injection moulding company, Packson Mold is willing to offer you high quality products.

Send product request

Other supplier products

| Custom Metal Machining Parts | Packson provides our customers a various CNC machining services to our customers, including milling, turning, grinding, drilling and more. Our t... | |

| Multi-cavities Injection Molding | Multi cavity mouldis an injection mold that has more than one cavity. The shape of each cavity is the same. Multi cavity mold designis to produce m... | |

| Prototype Injection Mould | Packsonmold is a company that provides high-quality prototype services, including 3D printing, CNC machining, micro-injection molding, and prototyp... | |

| Clean Room Injection | Packson - Clean Room Injection Expert Packson specializes in delivering top-notch clean room manufacturing and assembly solutions tailored to meet... | |

| Custom Contract Molding | Packson is the OEMinjection mold maker china. We can supply custom injection molding parts. Our high quality and precision injection molding proces... |

Same products

| Motorcycle Body and Frame Plastic Mold | Seller: Taizhou Huangyan Jingnan Moulding Co., Ltd. | As a key component mold professionally manufactured by Jingnan Mould, motorcycle body frame plast... | |

| For 2017 Audi A7 Rear Bumper Mould | Seller: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Mould Name Audi A7 Car Bumper Mould Material PP+EPDM(Contraction: 1, 5%) Bumper Size 1800*510*460... | |

| For Mercedes-Benz-C-206 Modified Bumper Mould | Seller: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Taizhou Huangyan Chenpeng Mold Co., Ltd. is a professionalwholesale Mercedes-Benz-C-206 Modified ... | |

| Front Bumper Lower Lip Mould For 2021 Honda CRV | Seller: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Introducing the for 2021 Honda CRV Front Bumper Lower Lip Mould: Elevate Your Driving Experienc... | |

| Bottle cap mold | Seller: Taizhou Huangyan Yongsheng Mould Co., Ltd. | Taizhou Yongsheng Mould Co., Ltd. can produce cap moulds ()within 64 cavities. The hot runner or ... |