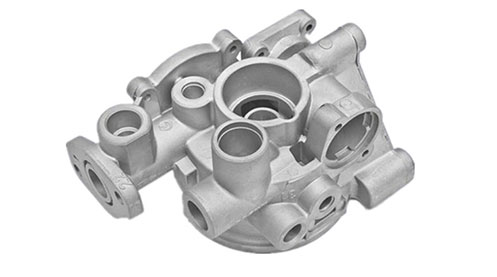

Aluminum Die Casting Mold

Aluminum Die Casting Mold

When working at high or low temperatures, they also maintain good mechanical properties and have good corrosion resistance. properties and antioxidant properties. Die castings are widely used in construction, hardware, equipment, machine tools, ships, aerospace, automobiles, electronics, computers, electrical appliances, lamps, and many other fields.

As a renowned high pressure die casting moldmanufacturer, Green Vitality is proud to offer its premium aluminium die casting mould. Our molds are expertly designed and constructed to meet the exacting demands of the die casting industry. Using top-grade aluminum materials, we ensure durability and heat resistance, guaranteeing a long-lasting and reliable mould die casting.

Aluminum Die Casting Applications

Aluminum pressure die casting mouldis used frequently in the automotive industry as a durable, lightweight alternative to steel and iron. Its electrical and thermal conductivity properties of the make it well suited for the telecommunications and computer industries. The lightweight of aluminium die casting mould makes it an excellent choice for portable applications.

Aluminum Die Casting Capabilities

Aluminum Die Casting Mold Specification

|

Material Capabilities |

Aluminum alloy, zinc alloy |

|

Molding Processes |

die casting |

|

Machine Size/ Clamping Force |

100 - 800 Tons |

|

Number of Cavities |

One or Multiple |

|

Production Volume |

5,000 units up to 100,000+ |

|

Manufacture time (day) |

30-45 days |

|

Quality Certifications |

ISO 9001:2015 |

Benefits Of Aluminum Die Casting Mould

Aluminium casting moldscan manufacture metal parts with complex shapes, clear outlines, thin walls, and deep cavities. Because molten metal maintains high fluidity at high pressure and high speed, metal parts that are difficult to machine by other processes can be obtained.

The material utilization rate is high. Due to the high precision of die castings, they can be assembled and used with only a small amount of machining.

High production efficiency. Due to high-speed filling, the filling time is short, the metal industry solidifies rapidly, and the die-casting operation cycle speed is fast.

Why Choose Green Vitality's Aluminum Die Casting Mould

As one of the best aluminium die casting mould manufacturers, Green Vitality is your best choice for several compelling reasons when you need aluminum die casting molds:

Precision Craftsmanship: Our aluminium die casting mould is meticulously crafted with the highest degree of precision, ensuring your final products meet exact specifications and quality standards.

Durable Materials: We use top-grade aluminum, renowned for its durability and heat resistance, making our molds long-lasting and reliable.

Innovative Design: Our die casting mould features innovative designs that optimize efficiency and performance, resulting in more efficient casting processes.

Customization: We understand the unique requirements of our clients. Our mould die casting can be tailored to meet specific design and production needs.

Technical Expertise: We have a team of experienced engineers and technicians who are always ready to assist you in selecting or customizing the right aluminium die casting moldfor your specific applications.

We Provide Full Service For Die Casting Projects

Green Vitality custom aluminum die casting injection moldsolutions include:

DFM and Design optimization Suggestions

Mold flow simulation analysis

Rapid prototyping

Custom Die Casting Tooling design

Die-casting

CNC and conventional machining

Surface finishing

Coatings, plating, painting

Assembly

Testing & Reports

Packaging &Delivery

We can offer sorts of injection molding dies for sale, if you have needs, please contact us.

Send product request

Other supplier products

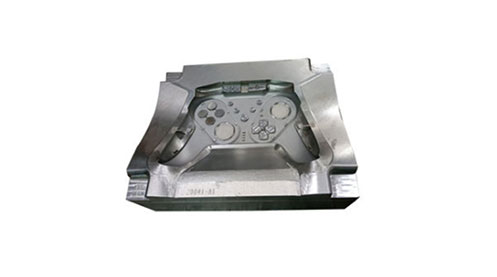

| Game Controller Mold | To increase the production efficiency, we need optimize the mold cooling system to shorten the cycle time. As a result, machining cost and time wil... | |

| Mouse Mold | One computer mouse usually includes these plastic parts: a bottom shell, an upper cover, a middle cover, a wheel, a base of wheel, a frame which co... | |

| Keyboard Mould | Mainly electronic molds we make are electronic housing mold, electronic components mold, electronic dashboard cover mold, computer keyboard mold, c... | |

| Plastic Food Container Mould | Plastic meal boxes mainly used for packing foods, so it need to be heat resistant and non-toxic,and could meet the requirements of environmental pr... | |

| Filter and Flow Limiting Apparatus | The family mold is used to produce injection parts for liquid filtration and flow monitoring and control systems. These accessories are custom... |

Same products

| Motorcycle Body and Frame Plastic Mold | Seller: Taizhou Huangyan Jingnan Moulding Co., Ltd. | As a key component mold professionally manufactured by Jingnan Mould, motorcycle body frame plast... | |

| For 2017 Audi A7 Rear Bumper Mould | Seller: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Mould Name Audi A7 Car Bumper Mould Material PP+EPDM(Contraction: 1, 5%) Bumper Size 1800*510*460... | |

| For Mercedes-Benz-C-206 Modified Bumper Mould | Seller: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Taizhou Huangyan Chenpeng Mold Co., Ltd. is a professionalwholesale Mercedes-Benz-C-206 Modified ... | |

| Front Bumper Lower Lip Mould For 2021 Honda CRV | Seller: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Introducing the for 2021 Honda CRV Front Bumper Lower Lip Mould: Elevate Your Driving Experienc... | |

| Bottle cap mold | Seller: Taizhou Huangyan Yongsheng Mould Co., Ltd. | Taizhou Yongsheng Mould Co., Ltd. can produce cap moulds ()within 64 cavities. The hot runner or ... |