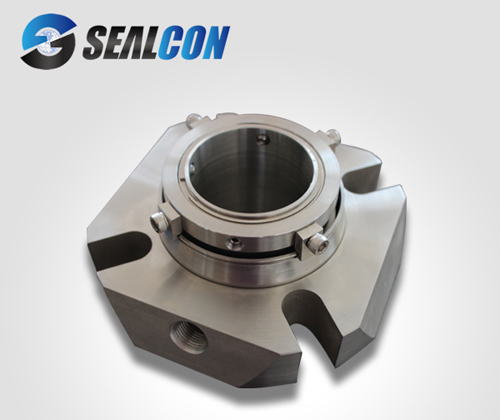

Single Cartridge Seals

Cartridge mechanical seal is assembled by the rotary ring, stationary ring, spring, secondary seal( o rings, PTFE), gland and other mechanical seal parts together as a collection, known as the cartridge seal, sometimes also called the cartridge mechanical seal.

Features ofSingle Cartridge Seals

- faster and easier replacement of pump shaft seals

- less downtime

- reliable start-up after a sealing change

A singlecartridge type mechanical sealconsists of two very flat surfaces that are pressed together by a spring and slide against each other. The singlemechanical seal is a mechanical seal composed of 1 set of seal face. the sealing structure is simple, easy to manufacture and install features. Generally used for the medium with good lubricity and allows a slight leakage. Single cartridge seals are the most commonly used mechanical seal type. Single cartridge pump seals do not work well when the media is the toxic, flammable, explosive and strict requirement of leakage.

Mechanical seals tend to leak a vapor from the high-pressure side to the low-pressure side. This fluid lubricates the seal faces and absorbs the heat generated from the associated friction, which crosses the seal faces as a liquid and vaporizes into the atmosphere. So, it's common practice to use a single mechanical seal if the pumped product poses little to no risk to the environment.

Advantage ofSingle Cartridge Seals

- ready-to-install: components include rotating components, bushingsandglands

- gage bolts appliedforthe most gland box

- easy to replace the packing or bearing

- easy to install in uneasy install place

- Used for longer time than non-cartridge mechanical seal

Disadvantages ofSingle Cartridge Seals

- the structure is more complex, high requirements for manufacturing and processing of mechanical seal ;

- installation and replacement is more complex, and requires workers to have a certain level of installation technology;

- in case of accidental accidents, more difficult to deal with;

- high investment than the non-cartridge mechanical seal.

MaterialofSingle Cartridge Seals

When a single cartridge seals used in the oil-filled motor, it is not only necessary to prevent the machine outside the impurities, sandandwater to enter, but also to prevent the leakage of oil within the machine ,So sealing requirements is higher, sealing ring material requirements need to be good, its sealing face material is made of tungsten carbide or silicon carbide. If it is installed on the shaft of the water-filled motor shaft, it only requires sand control. The sealing ring can be made of alumina ceramic, silicon nitride or other harder materials, so the cost is relatively low.

Recommended applications ofSingle Cartridge Seals

General industrial applications including chemical processing, foodandbeverage, petrochemical processing, pharmaceutical, wastewater and power generation.

Centrifugal pump, Chemical pump, Slurry pump, Mixer, Agitator, Circulation pump, Submersible electric pump, Reactor, Oil pump etc.

Difference betweenand non-cartridge mechanical seal

- Cartridge mechanical seal has a sleeve and gland; non-cartridge seals only have the rotary and stationary ring.

- The installation error rate of the Common non-cartridge mechanical sea is higher than the cartridge mechanical seal. Therefore, use cartridge shaft seal can greatly reduce the occurrence of mechanical seal failure.

- Since the cartridge mechanical seal does not require any adjustment of the mechanical seal by the installer (such as spring, sealing surface, etc.), only the bolts need to be tightened, which greatly improves the reliability of the mechanical seal installation.

Send product request

Other supplier products

| DIN Standard Double Cartridge Seals D21 with ANSI Bore Replacing Burgman Cartex DN | Double Cartridge Seals D21 Replacement for: BURGMAN CARTEX DN Features: DIN standard ANSI bore Performance Capabilities of cartex mechanica... | |

| Rubber Seal | China rubber ringseal is one of the common base components in sealing device, and plays an important role in the leaking and sealing. It is compose... | |

| MECHANICAL SEALS FOR PUMP | Mechanical seal for pump is a kind of dynamic seal assembly, which is widely used on the rotating shaft. It is also known as the end seal. Consisti... | |

| MECHANICAL SEALS FOR PUMP | Mechanical seal for pump is a kind of dynamic seal assembly, which is widely used on the rotating shaft. It is also known as the end seal. Consisti... | |

| Flygt Mechanical Seals FEU-22 | Flygt Mechanical Seals FEU-22 Replacement for: FEU-22 upper parts for flygt 2070 pump FEU-22 upper parts for flygt 2102-40 pump FEU-22 upper pa... |

Same products

| Quick-response Mechanical seal M74N-140 for power generation | Seller: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | "Quick-response Mechanical seal M74N-140 for power generation Is YOYIK for the use of turbine uni... | |

| Oil Seal 118*160*13 for Truck Auto Part Shaft NBR KDIK oil seal factory | Seller: Xingtai Honglei Seal Manufacturing Co., Ltd | Hot sale various high quality Truck oil seal from Chinaleading manufacturer. Our products are eff... | |

| Bh1941g Engine Timing Cover Seal Engine Camshaft Oil Seal | Seller: Xingtai Honglei Seal Manufacturing Co., Ltd | A Suzuki oil sealis a mechanical seal used to seal the gaps between the rotating shaft and the st... | |

| Transmission Oil Seal Bh4371e Tb 35*50*9.5 OEM for Toyota | Seller: Xingtai Honglei Seal Manufacturing Co., Ltd | Automotive oil sealsplay critical roles in different types of four wheeler vehicles. They are pri... | |

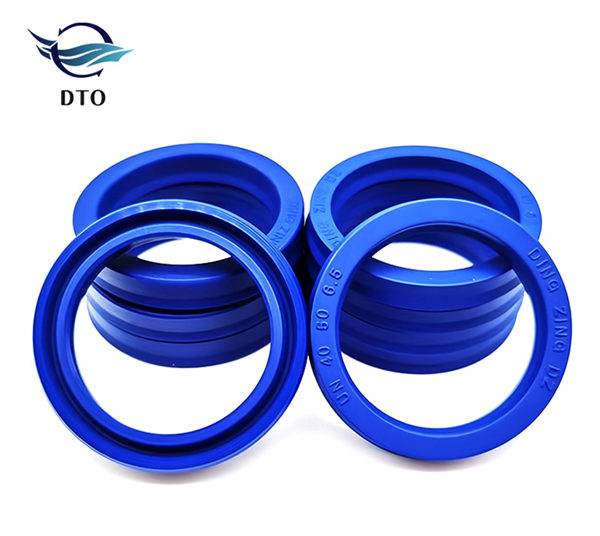

| UN Oil Seal | Seller: Xingtai Dingtong Rubber and Plastic Products Co., Ltd | A pliable, non-metallic PU ringis ingeniously nestled within a precision-machined groove or seaml... |