API Flange Cast Steel Swing Check Valve

|

Features: |

|

|

Size Range: |

1/2" up to 30" |

|

Pressure Range: |

ANSI 150LB to 2500LB |

|

End Connection: |

BW,RF,RTJ |

|

Material: |

Carbon Steel |

|

Seals: |

Metal to Metal |

Introduction toSwing Check Valve

Theis also called a or check valve, its role is to prevent the medium in the pipeline from flowing backward. The opening and closing part is opened or closed by the flow of the medium and the force to prevent the medium from flowing backward is called a check valve. The non-return valve is an automatic valve. It is mainly used for pipelines where the medium flows in one direction. It only allows the medium to flow in one direction to prevent accidents. This type of valve should generally be installed horizontally in the pipeline.

|

Standards: |

|

|

Valves Design: |

BS1868 |

|

Face to Face: |

ANSI B16.10 |

|

End Connection: |

ANSI B16.5, ANSI B16.25 |

|

Testing&Inspection: |

API6D, API598 |

|

Suitable Medium: |

Water, Oil, Air And Some Corrosive liquid |

Application of valve:

The swing check valve is suitable for nominal pressure PN1.0MPa ~ 42.0MPa, Class150-2500; nominal diameter DN15 ~ 1200mm, NPS1 / 2 ~ 48; working temperature - 196 ~ 540 ℃ on various pipelines to prevent Media is flowing backward. By using different materials (WCB, CF8 (M), CF3 (M), 1Gr5Mo, 15CrMo1V, it can be applied to various media such as water, steam, oil, nitric acid, acetic acid, strong oxidizing media, and urea. It is mainly used for petroleum, chemical, pharmaceutical, fertilizer, power, and other pipelines.

The adopts a built-in swing-arm swing structure. All the opening and closing parts of the valve are installed inside the valve body and do not penetrate the valve body. Except for the gasket and seal ring in the middle flange, the whole There is no leakage point, preventing the possibility of leakage of the valve.Swing check valverocker arm and valve disc adopt a spherical connection structure, so that the valve disc has a certain degree of freedom within a 360-degree range, with appropriate micro-position compensation. Suitable for clean media, not suitable for media with solid particles and high viscosity.

Structural features of the swing check valve:

The working principle of the swing check valve:

Through the up and down movement of the cylinder plug, the valve flap is opened and closed quickly to achieve the sealing surface

A structural form:

B drive method: butt welding connection

C connection form: butt welding connection

The opening and closing of the D valve are controlled by a pneumatic device to speed up the opening and closing of the valve.

Maintenance and maintenance of swing check valve:

1 The valve should be stored in a dry and ventilated room to prevent moisture, rain, and rust.

2 The storage and opening and closing parts should be in the closing device during storage and transportation.

The valve flap should be fixed to open, and the inner ports at both ends of the diameter should be blocked with foam boards. The ports must be plugged tightly to prevent dust and rust, to keep the passage clean and the end surface flat. And anti-collision; the valve should be stable when placed,

The pneumatic drives are facing up and must not be squeezed against each other.

3 It should be checked regularly when it is left for a long time. Every three months, check the dirt and rust on the two channels, the sealing surface, and the protection of the welding joint. After wiping the dirt and rust, apply anti-rust oil to protect it.

The swing check valve can be installed horizontally or vertically. Theswing check valveflap rotates around the axis of rotation. Its fluid resistance is generally smaller than that of a lift check valve. It is suitable for large-caliber occasions, and its installation position is not affected. Restricted, usually installed in horizontal pipelines, it is suitable for occasions with larger calibers. According to the number of valve flaps, it can be divided into three types: single-lobed revolving, double-lobed, and multi-lobed. A single flap swing check valve is generally used on the occasion of medium caliber. When large-diameter pipelines use , in order to reduce water hammer pressure, it is best to use slow-closing check valves that reduce water hammer pressure. A double flap swing check valve is suitable for large and medium diameter pipelines. Wafer double flap swing check valve has a small structure and lightweight and is a fast check valve. The multi-flap swing check valve is suitable for large diameter pipelines.

's swing check valve is widely used in chemical, metallurgy, pharmaceutical and other fields. Welcome to contact us!

A check valve, clack valve, non-return valve, reflux valve, retention valve or one-way valve is a valve that normally allows fluid (liquid or gas) to flow through it in only one direction.

Application scope: petroleum chemical industry, electric power, metallurgy, medicine, real estate, municipal engineering, and other industries.

click to visit our website.

Send product request

Other supplier products

| JIS FLANGE CAST STEEL SWING CHECK VALVE | Features: Size Range: 1/2" up to 24" Pressure Range: 10K To 40K End Connection: BW,RF Material: Carbon steel Seal... | |

| DIN FLANGE CAST STEEL SWING CHECK VALVE | Features: Size Range: 1/2" up to 12" Pressure Class Range: PN16 To PN100 End Connection: BW,RF,RTJ DIN Flange Swing Cla... | |

| JIS FLANGE CAST STEEL Y-STRAINER | Features: Size Range: 1/2" up to 24" Pressure Class Range: 10K To 40K End Connection: BW,RF Material: Carbon Steel ... | |

| API FLANGE STAINLESS STEEL BALL VALVE | API FLANGE STAINLESS STEEL BALL VALVE SPECIFICATIONS Features: Size Range: 1/2" up to 48" Pressure Range: A... | |

| THREAD SWING CHECK VALVE | Features: Size Range: 1/2" up to 4" Pressure Class Range: 200PSI,PN16 End Connection: BSP,BSPT,NPT Material: Stainles... |

Same products

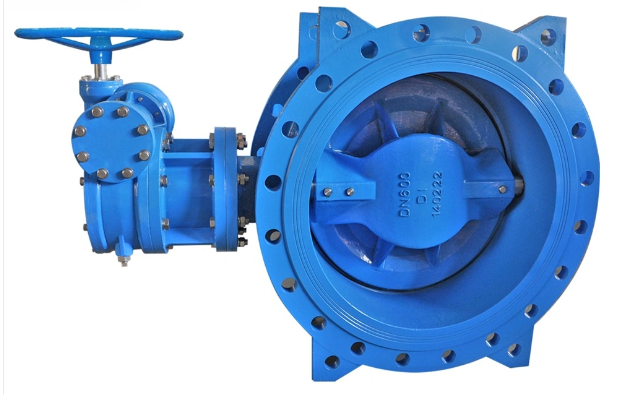

| China Wholesale High Performance Butterfly Valve Supplier | Seller: Tianjin Tanggu TWT Valve Co., Ltd. | High Performance Butterfly Valve Definition A high performance butterfly valveis a type of valve... | |

| China High Quality Ductile Iron Double Eccentric Butterfly Valve Pricelist | Seller: Tianjin Tanggu TWT Valve Co., Ltd. | Product Description Product Name ductile iron double eccentric butterfly valve ... | |

| China Wholesale AWWA C509 Gate Valve Factory | Seller: Tianjin Tanggu TWT Valve Co., Ltd. | Product Description Product Name AWWA C509 gate valve Manual Manu... | |

| Wholesale Resilient Seat Seal Groove Rising Stem Gate Valve Quotes | Seller: Tianjin Tanggu TWT Valve Co., Ltd. | Product Parameters Fluid medium Water, oil, gas, etc. Temperature Rang... | |

| China OEM Steel Gate Valve Series For Sale | Seller: Tianjin Tanggu TWT Valve Co., Ltd. | Product Description As a China industrial valves manufacturer, TWT introduces Steel Gate Valve S... |