Nipple Pipe Fittings

Nipple Pipe Socket are made from seamless steel pipes only and nipples cab be made from both seamless and ERW pipes, all Nipple Pipe Socket are made according to standard of BS2387,ANSI/ASTM A733.DIN2982,JIS B2302.Annual output is 2000 tons, the quanlity full guaranteed size suppliable from 1/8" to 6".

Nipple Pipe Socket Technical Specifications

Pipe Nipple Lengths, inch

Close 3/4 7/8 1 1 1/8 1 3/8 1 1/2 1 5/8 1 3/4 2 2 1/2 2 5/8 2 3/4 2 7/8 3 3 1/8 3 1/2 3 7/8 4 1/2

Length 1 1/2 1 1/2 1 1/2 1 1/2 1 1/2 1 1/2

2 2 2 2 2 2 2 2

2 1/2 2 1/2 2 1/2 2 1/2 2 1/2 2 1/2 2 1/2 2 1/2 2 1/2

3 3 3 3 3 3 3 3 3 3 3

3 1/2 3 1/2 3 1/2 3 1/2 3 1/2 3 1/2 3 1/2 3 1/2 3 1/2 3 1/2 3 1/2

4 4 4 4 4 4 4 4 4 4 4 4 4

4 1/2 4 1/2 4 1/2 4 1/2 4 1/2 4 1/2 4 1/2 4 1/2 4 1/2 4 1/2 4 1/2 4 1/2 4 1/2 4 1/2 4 1/2

5 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5

5 1/2 5 1/2 5 1/2 5 1/2 5 1/2 5 1/2 5 1/2 5 1/2 5 1/2 5 1/2 5 1/2 5 1/2 5 1/2 5 1/2 5 1/2 5 1/2 5 1/2

6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6

7 7 7 7 7 7 7 7 7 7 7 7 7 7 7 7 7 7

8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8

9 9 9 9 9 9 9 9 9 9 9 9 9 9 9 9 9 9

10 10 10 10 10 10 10 10 10 10 10 10 10 10 10 10 10 10

11 11 11 11 11 11 11 11 11 11 11 11 11 11 11 11 11 11

12 12 12 12 12 12 12 12 12 12 12 12 12 12 12 12 12 12

13 13 13 13 13 13 13 13 13 13 13 13 13 13 13 13 13 13

14 14 14 14 14 14 14 14 14 14 14 14 14 14 14 14 14 14

15 15 15 15 15 15 15 15 15 15 15 15 15 15 15 15 15 15

16 16 16 16 16 16 16 16 16 16 16 16 16 16 16 16 16 16

17 17 17 17 17 17 17 17 17 17 17 17 17 17 17 17 17 17

18 18 18 18 18 18 18 18 18 18 18 18 18 18 18 18 18 18

19 19 19 19 19 19 19 19 19 19 19 19 19 19 19 19 19 19

20 20 20 20 20 20 20 20 20 20 20 20 20 20 20 20 20 20

21 21 21 21 21 21 21 21 21 21 21 21 21 21 21 21 21 21

22 22 22 22 22 22 22 22 22 22 22 22 22 22 22 22 22 22

23 23 23 23 23 23 23 23 23 23 23 23 23 23 23 23 23 23

24 24 24 24 24 24 24 24 24 24 24 24 24 24 24 24 24 24

DN A B C D

6 15 17 15 8

8 18.5 25 18.5 11

10 21.3 26 21.3 12

15 26.6 34 26.6 15

20 31.8 36 31.8 17

25 39.5 43 39.5 20

32 48.3 48 48.3 22

40 54.5 48 54.5 22

50 66.2 56 68 26

65 82 65 84.2 30

80 95 71 98.4 34

100 121.4 83 124 40

125 146.3 92 149 44

150 173.3 92 177 44

Nipple Pipe Socket Advantages

It is convenient to get the material. Nipple Pipe Socket are made from the pipe which is easy to get.

Easy to install, just screw in.

Nipple & socket's length can be customized according to customer requirements

Nipple socket's production process is not competitive, manufacture cost is not high, it is cost-effective.

Nipple Pipe Socket Manufacturing Process

The technological process of manufacturing steel pipe fittings and nipple sockets is simple. Firstly purchase the manufacturing material pipe, then we need to inspect the pipe material quality, thirdly the raw material needs to be automatically cut off as per standard or client's requirement, Forth threads tapping, and stamping, Last but not least inspection the Nipple Pipe Sockets.

For more information about valves and lug type butterfly valve, please feel free to contact us!

Other supplier products

|

|

90° Elbow Varnish Paint Seamless Buttweld |

The extension line of the two nozzles of the 90° Elbow is vertical, and the two sides formed a right angle after taking over, which is the most... |

|

|

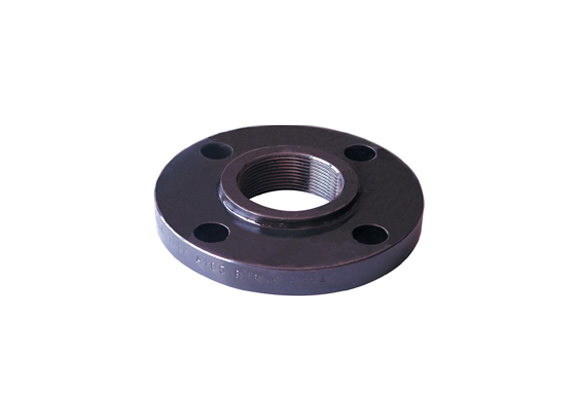

ANSI 150 Flange |

ANSI 150 flange, the standard flange with pressure grade CLASS150 (150LB), is the most widely used pressure flange in practice, its relevant flange... |

|

|

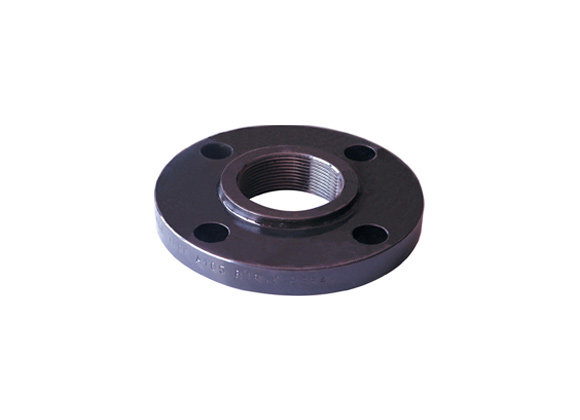

ANSI 150 Flange |

ANSI 150 flange, the standard flange with pressure grade CLASS150 (150LB), is the most widely used pressure flange in practice, its relevant flange... |

|

|

LSAW Pipes |

LSAW Pipe (Longitudinal Submerged Arc-Welding Pipe), DSAW pipe (Double Submerged Arc Welded Steel Pipe), Both of them are made of Steel raw materia... |

|

|

Rubber Expansion Joints |

Rubber expansion joints are used in the transportation of pressurized fluids. As they eliminate the need for coupling gaskets they are widely used ... |

All supplier products

Same products