PVC Sheet Extrusion Line

1.Uniformed and Even Plasticization 2. PLC Controlled, High Precision 3.CE, ISO, GOST,SGS Certification 4.Life Long Service PVC Sheet Extrusion Line THIS EXTRUSION LINE CONSISTS OF : 1. Spring Feeding Machine 2. Double Screw Extruder 3. T-Type Die Head 4. Three-roller Calendar 5. Cooling Frame 6. Edge Cutting Machine 7. Hauling off Machine 8. Knife Cutting Machine 9. Stacker Techincal Details about this Extrusion Line: 1. ZJF-700 Spring Feeding Machine 1 set Item Description Unit ZJF-700 1 Feeding Capacity Kg/h Max.1000 2 Container Volume Kg 150 3 Spring Diameter mm φ59 4 Feeding Tube and Spring Length mm 3-5 5 Material Trunk Volume Kg 200 6 Electric Power 3-380V 50Hz 7 Main Motor Power Kw 2.75 8 Dimensions mm 950×950×960 Φ820×1550 9 Total Weight Kg 250 1.2 Double-Screw Extruder type SJSZ65/132 1 set Item Description Unit SJSZ65/132 1 Output Capacity Kg/h Max.250 2 Number of the Screws 2 3 Diameter of the Screw mm 65/132 4 Rotating Direction of the Screws Forth & Reverse 5 Rotation Speed of the Screw r/min 1-34.7 6 Available Working Length of the Screws mm 1430 7 Main Motor Power Kw 37 8 Speed Adjusting Mode frequency conversion adjustable, Invertor from Innovance 9 Gear reducer Rigid-gear surface low noise design 10 Heating Capacity of the Screw barrel Kw 24 ( casting-aluminium electric-thermal elements ) 11 Material of the Screws and the barrel 38CrMoA1 12 Nitriding Depth of the Screws and the barrel mm 0.5~0.7 13 Nitriding rigidity of the Screws and the barrel HRC 50~55 14 Cooling Mode of the Screw barrel by air cooling 16 Indicators temperature indication by gauge 17 Temperature controllor Brand: Omron, Japan 18 Element of Electric System ( contactors, buttons, switches ) Brand: Schneider 19 Power of the Vacuum Pump Kw 1.5 20 Max. Vacuum Degree MPa -0.093 21 Cooling Water Consumption L/min 1~3 22 Plastic Material Feeding Mode By Fixed-quantity Screw Feeding Device 23 Rotation Speed of the Feeding Screw R/min 3.5~47 ( frequency conversion ) 24 Height of the Screw Axes mm 1000 25 Figure Dimensions ( L×W×H ) mm 4235×1520×2450 26 Weight Kg 4000 1.3 T -die head, 1 set Item Description Unit 1350mm 1 Die width mm 1350 2 Adjusted thickness mm 0.2-1.2mm 1.4 Three roller calendar 1 set Discription Unit 1 Roller motor power KW 3*3 sets 2 Speed adjusting inverter INNOVANCE 2 Roller width mm 1400 3 Roller mm 350 5 Chromed thickness mm 0,05-0,06 6 Roller wall thickness mm about 35 7 Roller adjusting Electrical, manual 8 Thermocontrol Mould thermocontroller, 1 set 1.5 Cooling Frame and Edge Cutting Unit 1 set Item Description Unit 1 Diameter of Roller mm 63mm 2. Length of cooling frame mm 4000 3 Material of cooling roller Stainless Steel 4 Method of edge cutting knife 1.6 Haul off Machine 1 set Item Description Unit 1 Length of rubber rolls mm 1350 2 Clamping method Pneumatic 3 Driving motor kw AC, 4kw, ABB inverter 4 Hauling speed m/min 0.5-4.5 5 Clamping Force Pneumatic 1.7 Guillotine- knife cutting machine and Stacker 1 set Item Description Data 1 Main Motor Power 3 kw 3 Available Cutting Width 1350 mm 4 Available Cutting Thickness 0.3-2mm 5 Working Height 800 mm 6 Figure Dimension 1860*2210*1180mm

Send product request

Other supplier products

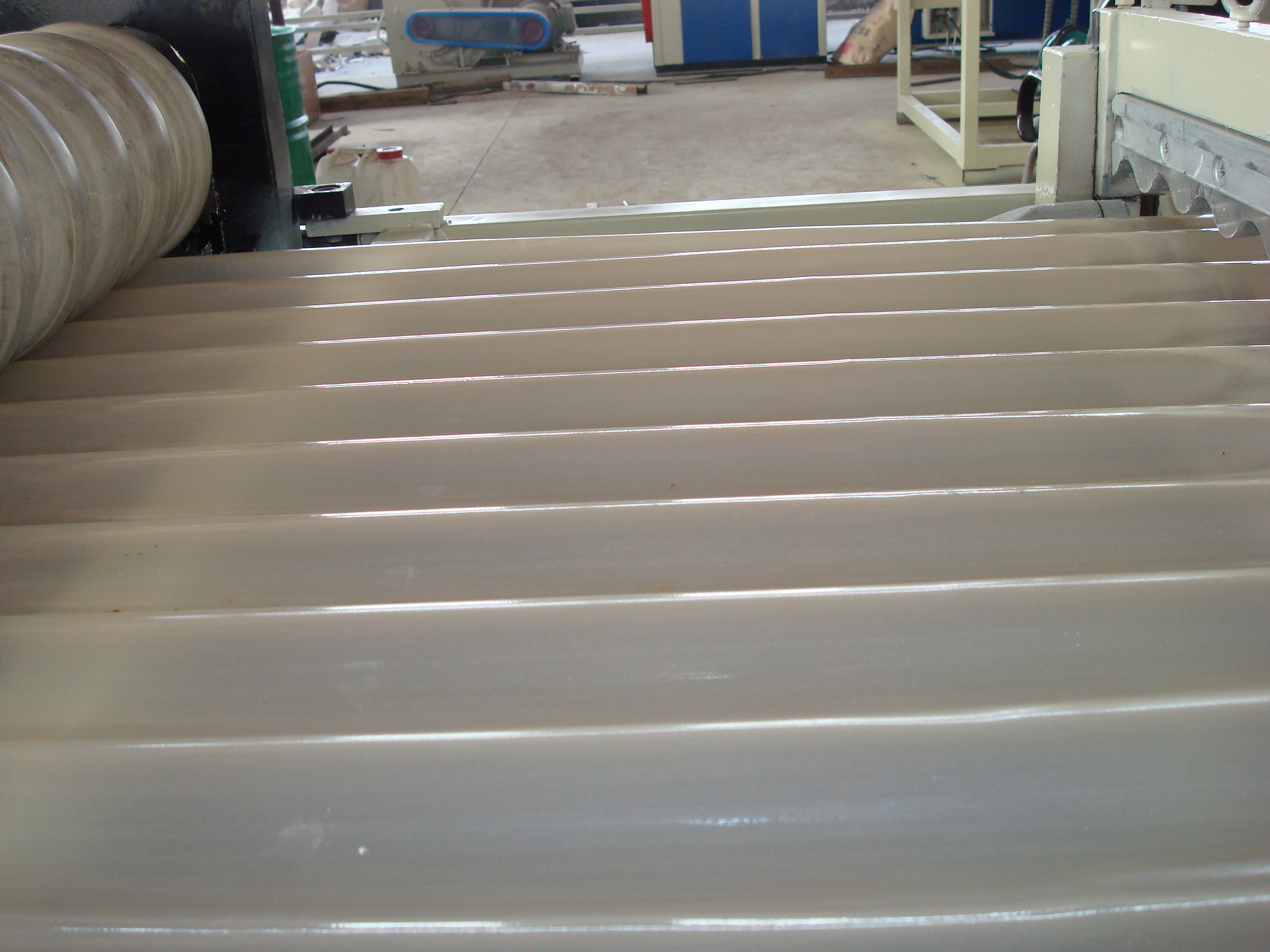

| PVC/PP Corrugated Sheet Extrusion | Wave plate has an excellent corrosion resistance, weather resistance, easy processing, low cost and many other characteristicsm abd is widely used ... | |

| UPVC/CPVC Water Supply/Drainage Pipe Extrusion Line | Using advanced design concepts to ensure the efficient extrusion of PVC powder, combined with the unique concept of plasticization screw design to ... | |

| FPR (PPR+GF+PPR) pipe extrusion line | Diameter range of 20-160mm, Maximum line speed up to: 10m/min FEATURES OF THIS EXTRUSION LINE: This extrusion line is consist of the single screw e... | |

| PVC skirting extrusion line | PVC skirting extrusion line 1.High output capacity 2.Low energy consumption 3.High precise 4.Long using life PVC skirting extrusion line main feat... | |

| UPVC Double Pipe Extrusion Line | The main extruder of this line is LSZ51/105 or LSZ65/132 twin screw conical extruder, installed with single controlled double pipe spraying water... |