TSP for drill bit

TSP for drill bit

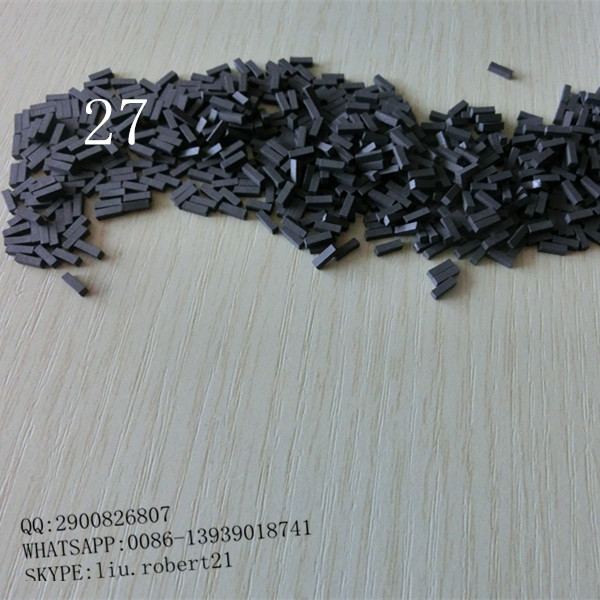

Thermal Stable Polycrystalline Diamond TSP Insert,Polycrystalline Diamond TSP Insert, TSP diamond cutter

tsp insert is anunbacked polycrystalline diamond product,which is manufactured by the same ultra-high pressure and high temperature techniquesasother PCDproducts.It is thermally stable up to 1200 degreefor its binder is chemically insert and has a similar coefficient of thermal expansionlike that of diamond.It is suitable for mining bits and oil drilling bits.

Different shapes and sizes, such as cylinders, triangles, rounds, rectangles, sharps, cubes, etc.

Rectangle:1.5*1.5*3.5,1.5*1.5*4,1.5*1.5*5,2*2*10,3*3*10,4*4*10,etc.

Triangle :4*4*4*2.6,4*4*4*3,6*6*6*4.5,6.2*6.2*6.2*4.3,etc.

Cylinders:1.5*4,1.8*4,2*4,3*8,4*10,5*10,6*10, 6.3*3.3,6.5*3.3,8*3,10*2,10*3, etc.

Rectangle:1.5*1.5*3.5,1.5*1.5*4,1.5*1.5*5,2*2*10,3*3*10,4*4*10,etc.

Triangle :4*4*4*2.6,4*4*4*3,6*6*6*4.5,6.2*6.2*6.2*4.3,etc.

Cylinders:1.5*4,1.8*4,2*4,3*8,4*10,5*10,6*10, 6.3*3.3,6.5*3.3,8*3,10*2,10*3, etc.

Application:

Different TSP products with different performances of wear-resistance, toughness, self-sharpening & high-temperature resistance can be used in gem-processing, wire drawing dies, coated cutters, etc. It can be applied on the drill bits for oilfields.

More Detailed Description:

What is TSP?

Thermal Stable Polycrystalline Diamond(TSP),it has excellent thermal stabilitythan PCD,so it's mainly used in Oil&Gas Drilling,geological drilling and bit reamer,metal processing.

Where DoTSPUse?

- Metal Processing

- Oil well drilling bit

- Geological drilling bit

- Drill bits and bit reamer

- Gas Drilling

Why ChooseTSP?

- Excellent wearability than PCD series

- It is the best choice for Oil&Gas Drilling

- Itis selected in a higher degree.

- Use a new type of tungsten carbide,which improved the strength character of bonding.

- Great Thermal Stability and T/T Data

- Use new super heat-resistant metal, to avoid being contaminative during sintering .

Send product request

Other supplier products

| resin bond superabrasive grinding disc | Main features: efficient batch double and single side grinding high wear resistance and long working life high parallelism and flatness of worpiec... | |

| TSP for drill bit | TSP for drill bit Thermal Stable Polycrystalline Diamond TSP Insert,Polycrystalline Diamond TSP Insert, TSP diamond cutter tsp insert is anunbac... | |

| 1A1 vitrified bond diamond bruting wheel | Vitrified bond diamond bruting wheel also call ceramic bond diamond bruting wheel, it used for grinding of single of single crystal diamond, this w... | |

| Polycrystalline diamond(PCD) Cutting Tool Inserts For Machining Mirror Resin Lens | : PCD inserts for resin lens have high hardness, high speed and wear resistance, etc.More SuperHard offers a complete range of diamond tools for ... | |

| Vitrified bond diamond cup abrasive wheel | Vitrified Bond Diamond & Cbn Grinding Wheel:1)Vitrified Bond Diamond & Cbn Grinding Wheel2)High quality Vitrified Bond Diamond & Cbn Gr... |