Soldering & Brazed PCBN Inserts

Details

Our Solid PCBN / CBN Inserts Display A Serious Of Preminum Performance, Such As Strong Corrosion Resistant, Perform A Good Thermal Stability And Red-Hardness, Suitable To Process Cast Iron, Quenched Steel And Other Kinds Of Ferrous Metal.CBN Polycrystalline Block Cutter Of Our Company Shall Greatly Improve Cutting Speed And Realize Real High-Speed Cutting; Meanwhile It Is Fit For Continuous Processing; Dry Cutting Causes No Pollution And No Noise. Currently Our Company Can Provide Round,Cube, Square And Triangle Solid PCBN Inserts (Polycrystalline Cubic Boron Nitride).

More Superhard PCBN Cutter Insert ( Polycrystalline Cubic Boron Nitride) Mainly Used For Ferrous Materials Machining,Like Gray Cast, Cast Iron,Carbon Steels, Alloy Steels, Nickel Or Cobalt, Etc... PCBN Diamond (Polycrystalline Cubic Boron Nitride) Products Is Second Only ToDiamondIn Hardness. The Hardness Allows The Ability To Machine Hardened Work Pieces. The High Thermal Conductivity Of PCBN Allow For An Increase In Tool Life Over Carbide Tools. Furthermore, The High Chemical Stability Allows For PCBN To Be Stable Up To 1000° C And No Reaction With Fe, Ni, CO Etc... Allowing Easy Grinding And EDM Cutting.

Features of soldering brazed PCBN inserts:

* High chemical resistance stability

* High hardness and abrasive resistance

* Strong impact resistance

* Good fracture resistance

* High working efficiency

* Dry cutting

Applications of soldering brazed PCBN inserts:

Idea for machining hard ferrous metals, such as hardened steels, gray cast iron. PCBN inserts are widely used to machine brake discs, engine cylinder liners, engine blocks, break drumsticks, valve seats and guides, gears and mould,etc.

Specifications of Soldering brazed PCBN inserts:

|

inserts type |

dimension |

standard cutting edge |

||||||

|

L |

ø i.c |

s |

r |

ø d1 |

ø d2 |

|||

|

SCGW09T304-2S |

6 |

|||||||

|

SCGW09T308-2S |

6 |

|||||||

|

SCGW09T312-2S |

6 |

|||||||

|

inserts type |

dimensions |

standard cuttingedge |

||||

|

L |

ø i.c |

s |

r |

ø d |

||

|

TNGA160404-6S |

T01020T02020S01020S02020 |

|||||

|

TNGA160408-6S |

||||||

|

TNGA160412-6S |

||||||

|

TNGA220404-6S |

22 |

|||||

|

TNGA220408-6S |

22 |

|||||

|

TNGA220412-6S |

22 |

|||||

* Other Types Of brazed PCBN inserts Like WNGA,CCGW,DNGA,TNGA,SNGA,All Available Upon Request. For More Information, Please Click On The PDF Below.

Why choose our product

More SuperHard Products Co., Ltd is dedicated to finding solutions that help our clients in all markets succeed. More SuperHard has been manufacturing high-quality, competitively priced superabrasivediamond and cbn tools that are designed to perform in a wide range of industrial ,such as pcd tools grinding, natural diamond polishing, auto parts processing , thermal spray coated industry, optical glass, semicon and led industry, woodworking tool , cnc tool grinding and roll machining ,others ultral precision industry.

The company production and sales of products covered vitrified bond tools, resin bond tools, metal bond tools, electroplated diamond/cbn tools, vaccum brazed products, cvd diamond tools, polycrystalline diamond (pcd) tools, cubic boron nitride (cbn) tools.our objective is to meet all the customers’ needs and help every customer achieve maximum benefits. more brings in revenue for you, you win, we win!

More SuperHard supplies the wheels for several application mainly:

- Carbide round tools on cnc machines : flute grinding, gash grinding, end facing, clearance angle and cylindrical grinding .

- Insert grinding for machines such as: agathon, wendt, haas, waida and ewag.

- Woodworking saw blade and tools .

- Hss tools

- Cutting wheels

Products Range:

- 2. PCD milling tools, PCD turning tools, PCD drilling tools, PCD engraving tools, PCD/pcbn inserts, PCD/pcbn cutting tools, PCD/pcbn grooving tools, CBN inserts3. PCD/TSP diamond, CVD diamond tools, large size synthetic diamond, Natural diamond tools, diamond abrasive tools4. diamond grinding&cutting discs, diamond cutting blade, diamond cup wheel, diamond dressers5. Roller cutting tools, PDC cutters, PDC drill bits& PDC core bits6. PCD tool grinder & PCD grinding machine

Packaging and shipping

|

Packing |

Carton, plastic bag,or as your request |

|

Shipping |

we use DHL,UPS,FEDEX,ect.to ship the goods,or according to the customer's requirement |

|

Delivery time |

about3-7days, for special time according to your quantity |

Our services

FAQ:

A: yes, you can. We will give some discount according to your quantity.

- ’s production progress?

A: we will keep closely track the production and shipment progress. And we will inform you with the newest progress about producing and shipping.

A: We have pass the ISO 9001:2008. If there is any problem with our products, please send me the detailed picture of the problem, once we verify it, we will change the products for you within 30 days.

Q4: When I contact you is suitable?

You can contact Us at any time, we promise that we will reply you within 12 hours.

A:So, please contact me for more information about our product, service and related issues.

If you have any questions, please contact us

Whats App:

Tel:

URL:

To meet your requirements in every way, we need the following information

----- Shape and Dimension of the wheels

----- Grit size (Mesh, refer to Table#1)

----- Concentration

----- Bond(Resinoid, Vitrified, Metallic, Electroplated)

----- Quantity

Send product request

Other supplier products

| 11B2 CBN Superhard diamond grinding wheel | Introduction to resin bond: Resin wheel is a wheel made of resin, such as phenolic, epoxy, polyurethane, polyvinyl alcohol, etc.Resin grinding whe... | |

| Flexible Diamond Belts,Flexible Diamond Abrasive Tool Sanding Belt | Specification: The open dot pattern provides flexibility, aggressive cutting and reduced loading. The flexible backing also means they run great o... | |

| Dental Diamond Burs | Details: More SuperHard dental diamondburs are used for precise drilling and polishing of critical ceramic parts on high speed handpiece. Dental d... | |

| Glass resin grinding wheel is used in straight edge machine and chamfering machine | Introduction to resin diamond grinding wheel The resin bond diamond wheels are mainly used for grinding tungsten carbide and non-metal materials. ... | |

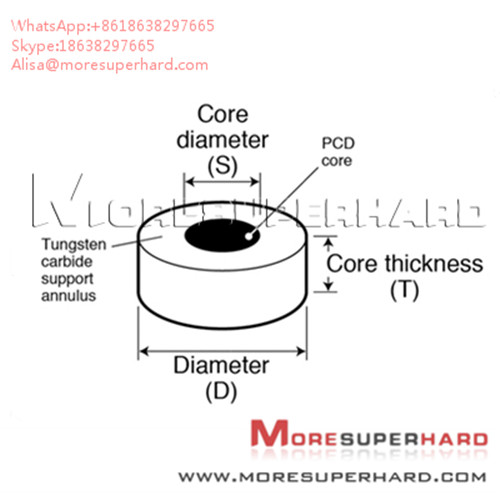

| Tungsten Carbide Supported Diamond Die Blanks used to wire drawing | Descriptions of Tungsten Carbide Supported Diamond Die Blanks: Tungsten carbide supported diamond die blanks is manufactured by means of cold pres... |