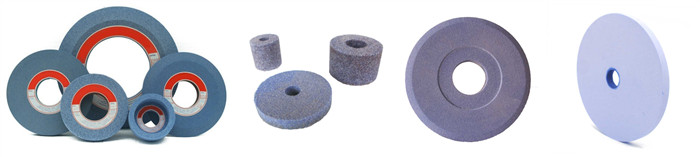

Grinding Wheel sets for CNC Machining centers

Work linear velocity: 35 m/s - 70 - m/s

Grit: 400#

Material:Diamond

Bonds:Resin

Type:1A1,1V1,11V9,12V9 ect

Size: 75-300mm

Process: Sintered

Roundness: <0.01mm

Manual/automatic: automatic

Grinding way:Wet

Application: CNC grinding wheel is mainly used for the overall carbide, high-speed steel, stainless steel drill bits, milling cutters and reamers and other CNC cutting tools, shovel back, the end of the tooth grinding

Application grinder: the United States Sac Australian ANKA (ANCA), Germany Walter (Walter), Germany Sutter (Schutte), Taiwan Ding Wei and other 5-axis CNC tool grinding machine.

Detail

CNC Tool Grinding Machine Diamond Grinding Wheel

CNC tool grinding machine with excellent stability and flexibility, the requirements of diamond grinding wheel is also unconventional diamond grinding wheel can be achieved, the strength of the grooved wheel cutting requirements of 4-5mm or even 7-8mm, while requiring good surface quality, because Large grinding contact surface, the coolant is difficult to be effectively utilized, therefore, in order to avoid the workpiece burn, using ordinary diamond grinding wheel can only take to reduce the amount of feed approach. And our new generation of RM Powerful Grinding Wheels, designed for use with CNC tool grinding machines such as ANCA, WALTER, SCHUTTE, EWAG, SCHNEEBERGER, HUFFMANN, etc., offers outstanding performance with very high spindle loads Cutting speed, a large amount of feed for a strong slot, the surface quality of the workpiece being machined, while maintaining a good wheel-shape retention.

CNC Tool Grinder Diamond wheel feature:

1, high-security type, suitable for high-precision tool production and processing;

2, a large amount of knife up to 4-7mm;

3, the workpiece surface finish is good

4, low spindle load;

5, high cutting speed;

6, grinding wheel sharp wear, long dressing cycle.

Performance Comparison of Grinding Wheel with CNC Tool Grinding Wheel and Conventional Bonding Agent

|

Resin bond |

Metal bond |

Vitrified bond |

RM powerful grinding wheel |

|

|

Cutting efficiency |

general |

general |

high |

high |

|

Free cutting |

general |

low |

high |

high |

|

Insurance type performance |

general |

high |

general |

high |

|

Fluting : Perfect Flute Surface Quality; Extremely High Stock Removal; Very Low Energy Consumption |

|||||

|

Model |

D (Mm) |

T (Mm) |

X (Mm) |

H (Mm) |

Grit |

|

1A1 |

75 |

10 |

5 |

20 |

D64 |

|

100 |

6, 10, 12 |

5, 10 |

20 |

D46, D64 |

|

|

125 |

10, 12, 16 |

10 |

20 |

D46, D64 |

|

|

150 |

12 |

10 |

20 |

D64 |

|

|

1V1 |

D (Mm) |

T (Mm) |

X (Mm) |

H (Mm) |

V° |

|

75 |

10 |

5 |

20 |

45 |

|

|

100 |

10, 15 |

5 |

20 |

45 |

|

|

125 |

6, 10, 15 |

5 |

20 |

45 |

|

|

150 |

12 |

5 |

20 |

45 |

|

|

14F1 ( Flute For Drill ) |

D (Mm) |

U (Mm) |

X (Mm) |

H (Mm) |

R |

|

100 |

4 |

6 |

20 |

2 |

|

|

125 |

3 |

5 |

20 |

||

|

150 |

1,5 |

5, 7 |

20 |

||

|

Gashing And Clear Edge:The Production Of Superior Tool Edge Quality ;High Stock Removal; Maintaining Wheel Profile |

|||||

|

Model |

D (Mm) |

T (Mm) |

X (Mm) |

H (Mm) |

V° |

|

1V1 |

100 |

10, 15 |

5, 10 |

20 |

45 |

|

125 |

4, 10, 15 |

5, 6, 10 |

20 |

45 |

|

|

12V9 |

D (Mm) |

W (Mm) |

X (Mm) |

H (Mm) |

|

|

75 |

3 |

10 |

20 |

||

|

100 |

3 |

10 |

20 |

||

|

125 |

3 |

10 |

20 |

||

|

150 |

3 |

10 |

20 |

||

|

Relief Angle Grinding: Excellent Surface Finish And The Best Profile Consistency;Excellent Edge Quality ;High Stock Removal At Second Relief |

|||||

|

12V9 |

D (Mm) |

W (Mm) |

X (Mm) |

H (Mm) |

|

|

75 |

3 |

10 |

20 |

||

|

100 |

2, 3 |

10 |

20 |

||

|

125 |

3 |

10 |

20 |

||

|

Other Specification Can Be Made According To Customers Requirements. Email: |

|||||

anna.wang

Send product request

Other supplier products

| cd Diamond Plate for Diamond Milling Cutter | Synthetic diamond single crystalare synthetic diamonds produced underhigh temperatureand high pressure(HTHP) conditions. We have a high quality ma... | |

| SG ( Sol Gel ) Grinding Wheel | Introduction of SG grinding wheel : Ceramic abrasives prepared by sol-gel methodis a kind of sintered abrasive , grain size is tiny, only 100- 500n... | |

| PCD External Grooving Tools | PCD External Grooving Tools PCDGrooving Tools Specification: PCD grooving tools also be called Diamond grooving tools, Slotting cutter,Grooving ... | |

| Vitrified Grinding Wheels For PCD & PCBN Tools | How to sharp the tools with PCD & PCBN inserts? Tools with PCD&PCBN inserts are very reten-tive, but demand an occasional sharpen-ing.In co... | |

| Resin bonded diamond wheels | Resin bonded diamond wheels are used for alloy grinding; Resin bonded CBN wheels are used for steel grinding. Resin bond diamond grinding whe... |

Same products

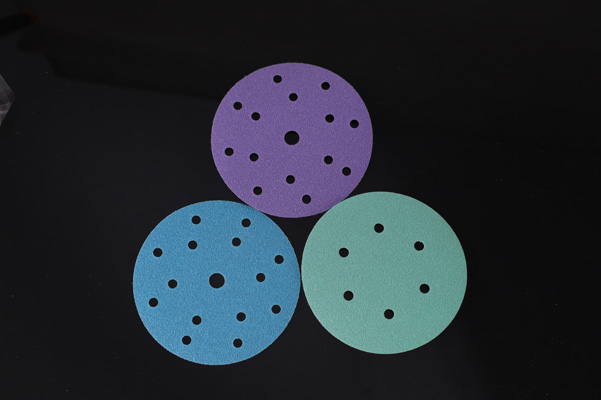

| AF38M Blue Abrasive Film | Seller: CHANGZHOU RMN ABRASIVES CO., LTD | RMC AF38M blue abrasive film can be used as Velcro and PSA disc, and also suitable for different ... | |

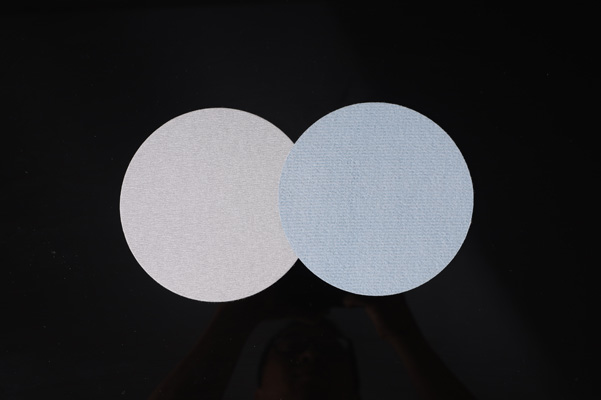

| AP36M Velcro Disc | Seller: CHANGZHOU RMN ABRASIVES CO., LTD | RMC AP36M abrasive velcro sandpaper discsimpregnated latex, flexible. Special super stearated coa... | |

| AP36M PSA Sanding Discs | Seller: CHANGZHOU RMN ABRASIVES CO., LTD | RMC AP36M abrasive paper PSA sanding discimpregnated latex, flexible. Special super stearated coa... | |

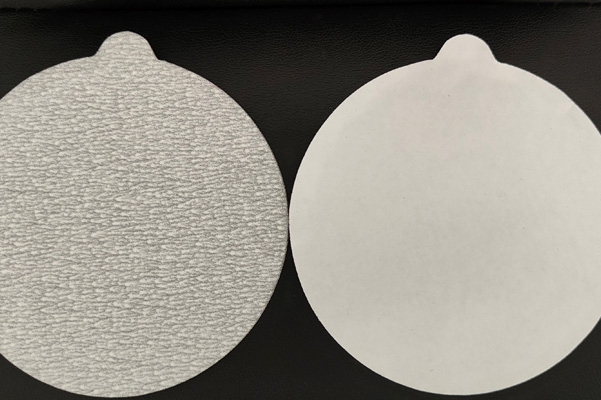

| AP33M Velcro Backed Sandpaper | Seller: CHANGZHOU RMN ABRASIVES CO., LTD | RMC AP33M velcro sanding paperroll is a special sandpaper product suitable for fast sanding. Prem... | |

| AP33M PSA Sanding Discs | Seller: CHANGZHOU RMN ABRASIVES CO., LTD | RMC AP33M PSA sanding discis a special sand paper product suitable for fast sanding. Premium alum... |