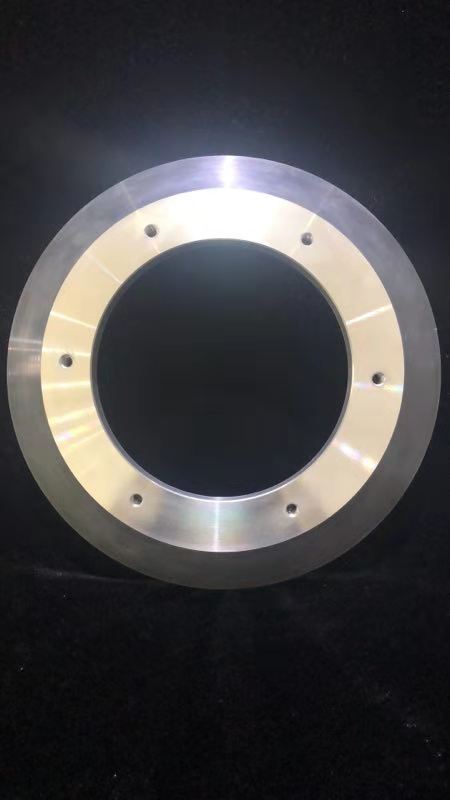

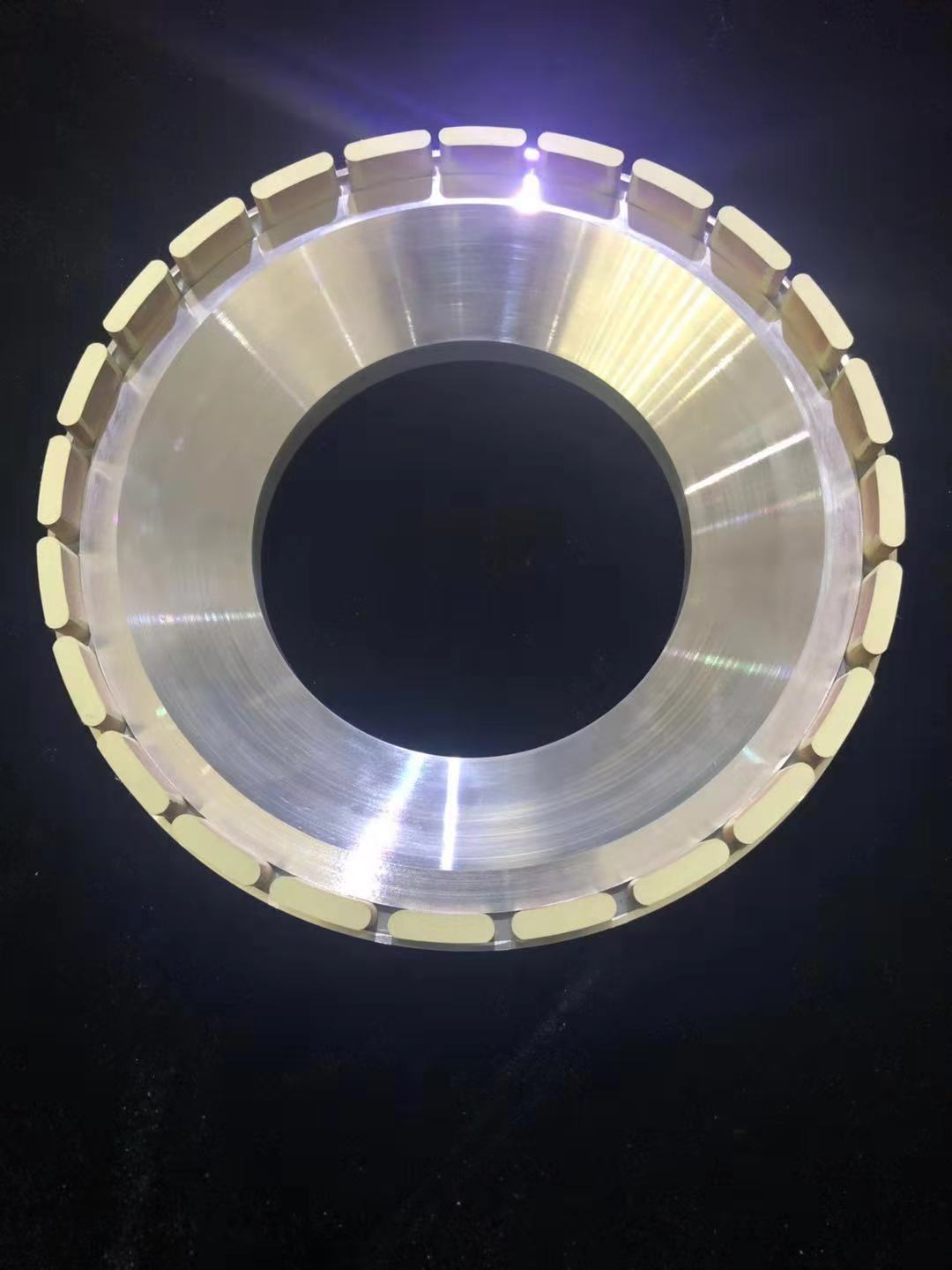

wafer back grinding wheel

Siliconwafer back grinding wheelsare mainly used for the thinning and fine grinding of the silicon wafer.

Coolant: Oil, emulsion

workpiece processed: silicon wafer of discrete devices, integrated chips (IC) and virgin,ATM, Melchiorre, Peter Wolters, Diskus, Viotto, Wendt

Material of workpiece: monocrystalline silicon and some other semiconductor materials.

Grinders: SHUWA SGM-6301, NTS Nanosurface-180G, NTS Nanosurface 250/NC-VDM

Main role of back grinding wheel

In the middle of the pre-production process, thick silicon wafer can reduce damage; before assembly, silicon wafer is thinned, which is conducive to heat dissipation; reduce package volume; improve mechanical strength (softer after thinning, softer after thinning, minus Small stress); improve electrical performance (short connection); reduce the workload of dicing wafer

Vitrified bond suitable for silicon wafer back grinding wheel

Vitrified bond diamond grinding wheel bond agent has higher strength; good wear resistance, sharp cutting Grinding efficiency is high, and easy to trim; generally suitable for silicon wafers, such as rough grinding, semi-finishing grinding, etc.

The diamond grinding wheel has good self-sharpening performance and is not easy to clog; the grinding efficiency is high, the grinding force is small, and the grinding temperature is low The bonding agent itself has good elasticity and polishing performance; the workpiece has high surface finish and good surface quality; it is suitable for fine grinding and polishing of silicon wafers.

The Specification Of Diamond Back Grinding Wheels:

|

Model |

Diameter (Mm) |

Thickness (Mm) |

Hole (Mm) |

|

6A2 |

175 |

30, 35 |

76 |

|

200 |

35 |

76 |

|

|

350 |

45 |

127 |

|

|

6A2T |

195 |

170 |

|

|

280 |

30 |

||

|

6A2T(Three Ellipses) |

350 |

35 |

235 |

|

209 |

158 |

||

|

Other Size Can Ba Made According To Customers Requirements |

|||

silicon wafer back grinding wheel features:

1, surface quality: require grinding lines evenly, without chipping, debris, scribe, etc.;

2, processing accuracy: TTV <5 μm etc. (Total thinning veracity);

3, processing quality: surface roughness: < 10 nm; damage layer thickness: < 10 μm;

Applicationof back grinding wheel

The grinding wheels for LED substrateare mainly used for back thinning of sapphire epitaxial wafer, silicon wafer, gallium arsenide and GaN wafer.

Workpiece processed: sapphire epitaxial wafer, silicon wafer, gallium arsenide and GaN wafer.

Material of workpiece: synthetic sapphire, single crystal silicon, gallium arsenide and GaN materials.

The LED substrate thinning grinding wheel is mainly used for the back surface thinning of the sapphire epitaxial wafer, silicon wafer, gallium arsenide and gallium nitride wafer in the LED industry. The grinding LED substrate grinding wheel developed by our company has superior grinding performance and high cost performance. It can be used stably in European, American, Japanese and domestic grinding machines, and can replace imported products.

Send product request

Other supplier products

| Diamond Coated Drill Bit//Electroplated Core Bits | Product Description 1. Shank: Straight shank2. Diameter: 1.5mm ---150mm3. Length: 40mm4. Segment Height: 10mm5. Wall Thickness: 1mm6. Machine: H... | |

| Glass Diamond Drill Bits - Threaded Shank Drill | Application of threaded shank drill bits: Diamond glass core drill bits are used to drill glass,ceramics, porcelain, ceramic,porcelain tile, limes... | |

| Blade Type Diamond Dressers | diamond dresser for grinding wheel diamond dressersare used for dressing specific forms into conventional abrasive grinding wheels require longer ... | |

| Big Rough Diamond plate | Synthetic diamond single crystalare synthetic diamonds produced underhigh temperatureand high pressure(HTHP) conditions. We have a high quality ma... | |

| wool buffing pad for car polis | cotton wool pad Product Description 100% wool felt polishing wheel 1)Felt polishing wheel use the imported wool as raw materials, which Not on... |

Same products

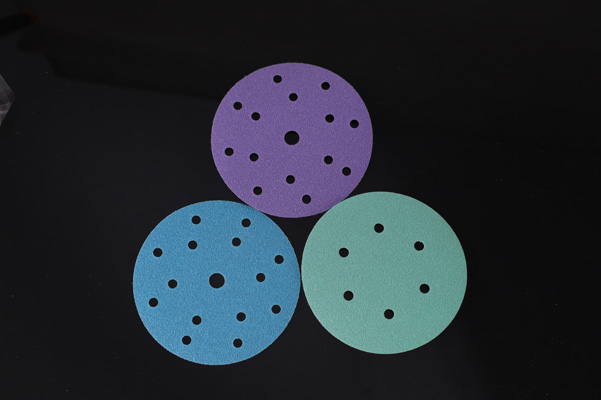

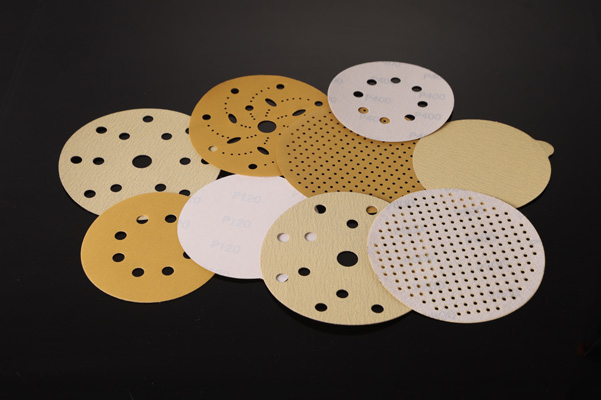

| AF38M Blue Abrasive Film | Seller: CHANGZHOU RMN ABRASIVES CO., LTD | RMC AF38M blue abrasive film can be used as Velcro and PSA disc, and also suitable for different ... | |

| AP36M Velcro Disc | Seller: CHANGZHOU RMN ABRASIVES CO., LTD | RMC AP36M abrasive velcro sandpaper discsimpregnated latex, flexible. Special super stearated coa... | |

| AP36M PSA Sanding Discs | Seller: CHANGZHOU RMN ABRASIVES CO., LTD | RMC AP36M abrasive paper PSA sanding discimpregnated latex, flexible. Special super stearated coa... | |

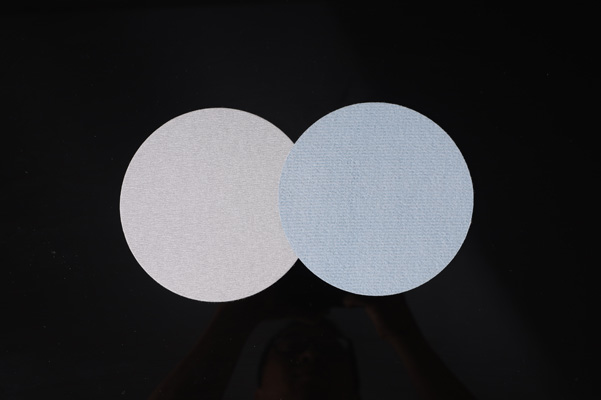

| AP33M Velcro Backed Sandpaper | Seller: CHANGZHOU RMN ABRASIVES CO., LTD | RMC AP33M velcro sanding paperroll is a special sandpaper product suitable for fast sanding. Prem... | |

| AP33M PSA Sanding Discs | Seller: CHANGZHOU RMN ABRASIVES CO., LTD | RMC AP33M PSA sanding discis a special sand paper product suitable for fast sanding. Premium alum... |