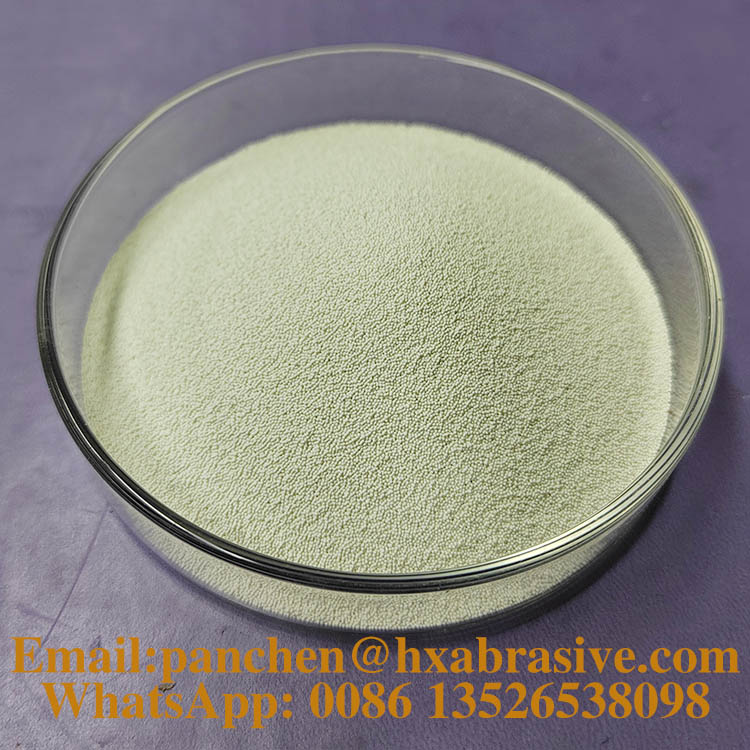

Zirconia beads microsphere B170 B205

Zirconia beads microsphere B170 B205

The main component of ceramic shot is zirconia, which is mainly used for surface treatment such as sand blasting and shot peening. The production process of ceramic shot is to melt high-quality imported zircon sand into liquid at high temperature, and then spray it into balls. The zirconia ceramic spheres are sieved and removed by magnetic separation to obtain particles with high roundness, high strength and uniform particle size. The spherical particles of ceramic shot can achieve better surface brightness during sandblasting, while the workpiece itself does not change color. It is widely used for sandblasting and surface treatment of aviation parts, stainless steel plates, structural parts, stainless steel kitchenware, medical devices, mobile / laptop shell, automobile chassis / engine, sports equipment and other industries.

Characteristics of ceramic shot:

Chemical composition of ceramic shot:

|

Chemical |

Typical value(%) |

Value range(%) |

|

ZrO2 |

60-70 |

|

|

SiO2 |

28-33 |

|

|

AL2O3 |

Max 10 |

|

|

Fe2O3 |

Max 0.1 |

|

|

TiO2 |

Max 0.4% |

Physical features of ceramic shot

|

Mohs Hardness |

|

|

Vickers Hardness/ Rockwellhardness |

700HV/60HRC |

|

Specific gravity |

|

|

Bulk density |

Size >125um:2.30g/cm3,size<125um:2.1-2.2g/cm3 |

Specification:

|

Specification |

Particle size range |

|

B20 |

600-850 um |

|

B30 |

425-600 um |

|

B40 |

250-425 um |

|

B60 |

125-250 um |

|

B80 |

180-250 um |

|

B100 |

125-180 um |

|

B120 |

63-125 um |

|

B125 |

0-125 um |

|

B170 |

45-90 um |

|

B205 |

0-63 um |

|

B400 |

30-63 um |

|

B500 |

10-30 um |

*Other customized sizes are available.

Applications:

Ceramic shot is suitable for materials as below:

Send product request

Other supplier products

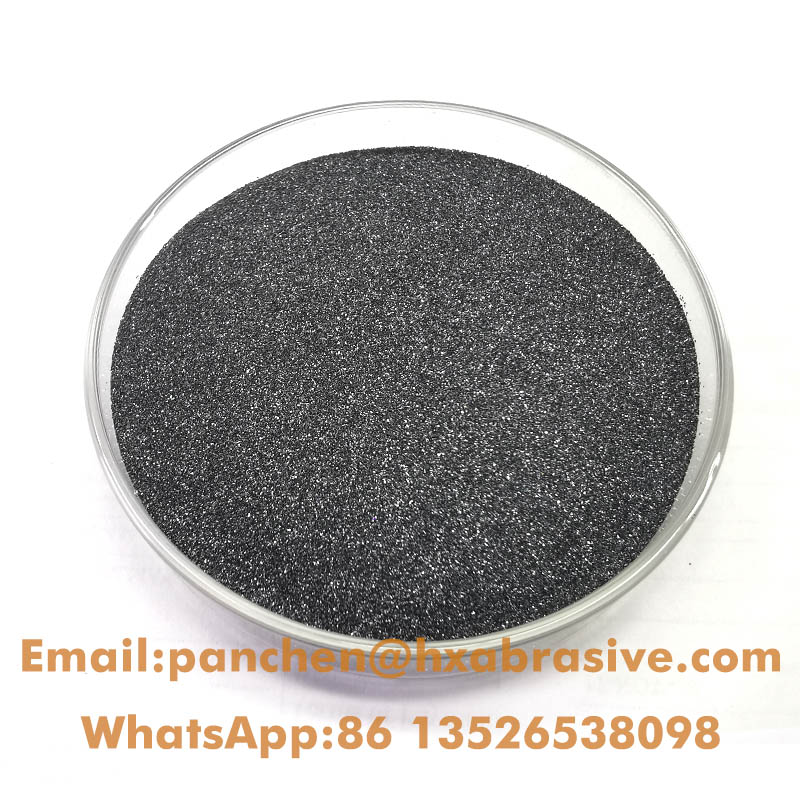

| Abrasive grain Green silicon carbide 64C F60 F80 | Green silicon carbide grit Green silicon carbide grit is a very hard abrasive material . The hardness of itonly ranks after diamond and B4C, and it... | |

| Silicon carbide Black 53C F120 F150 grinding powder | Black Silicon carbide Grain is an extremely hard and 99% SiC carborundum grit. As an abrasive material, it can work well for abrasive blasting, sur... | |

| Green Carborundum powder α-SiC 64C F1200 for ceramics | Green Carborundum powder α-SiC 64C F1200 for ceramics Green silicon carbide powder is a very hard abrasive material with uniform particle si... | |

| Silicon carbide powder 64C M50 M40 M28 | Silicon carbide powder 64C M50 M40 M28 Green silicon carbide powder is a very hard abrasive material with uniform particle size distribution. Th... | |

| Silicon carbide Black powder 54C F180 F220 Abrasive Grit | Black Silicon carbide Grain is an extremely hard and 99% SiC carborundum grit. As an abrasive material, it can work well for abrasive blasting, sur... |

Same products

| Fabric thickness tester | Seller: Qinsun Instruments Co., LTD | Fabric thickness tester mainly used to measure the thickness of the fabric, suitable for leather,... | |

| Dresser, 0.4 Carat Single Point Grinding Wheel Tapered Point Tool for Dressing and Grinding Bench, Item surface, Cylindrical Internal Grinding | Seller: 青岛晟鑫杰金刚石工具有限公司 | ||

| Aluminum Oxide Fiber Disc | Seller: CHANGZHOU RMN ABRASIVES CO., LTD | Aluminum Oxide Fiber Disc It is strong and has durable, long sanding life, high sanding performa... | |

| AJ26M Abrasive Belts for Metal | Seller: CHANGZHOU RMN ABRASIVES CO., LTD | AJ26M Abrasive Belts for Metal RMC AJ26M abrasive belts for metal backing is Jwt flexible and hi... | |

| AJ25 Aluminium Oxide Abrasive Belts | Seller: CHANGZHOU RMN ABRASIVES CO., LTD | AJ25 Aluminium Oxide Abrasive Belts The backing cloth make anti-slip treatment with high strengt... |